Kaizen as Operational Strategy Training Ppt

The PowerPoint Module on Kaizen as Operational Strategy outlines a structured approach to Kaizen implementation, providing practical guidelines and a roadmap to ensure successful integration into business practices. It begins by detailing the Kaizen Implementation Process. Next, it offers Guidelines for Kaizen Implementation, highlighting the need to identify areas with potential for improvement, analyze existing workflows for inefficiencies, brainstorm innovative solutions, plan effectively for implementation, and critically assess the outcomes. It also includes a Roadmap for Kaizen Implementation. The PPT Deck covers the Challenges to Kaizen Implementation, acknowledging common obstacles such as perceptions of Kaizen as a short term project, lack of adequate resources, goal setting miscalculations, internal and external resistance, and inconsistent efforts. Finally, it concludes by defining the Qualities of a Kaizen Leader. The PPT also has Key Takeaways and Discussion Questions related to the topic to make the training session more interactive. The deck contains PPT slides on About Us, Vision, Mission, Goal, 30 60 90 Days Plan, Timeline, Roadmap, Training Completion Certificate, Energizer Activities, Client Proposal, and Assessment Form.

The PowerPoint Module on Kaizen as Operational Strategy outlines a structured approach to Kaizen implementation, providing ..

- Google Slides is a new FREE Presentation software from Google.

- All our content is 100% compatible with Google Slides.

- Just download our designs, and upload them to Google Slides and they will work automatically.

- Amaze your audience with SlideTeam and Google Slides.

-

Want Changes to This PPT Slide? Check out our Presentation Design Services

- WideScreen Aspect ratio is becoming a very popular format. When you download this product, the downloaded ZIP will contain this product in both standard and widescreen format.

-

- Some older products that we have may only be in standard format, but they can easily be converted to widescreen.

- To do this, please open the SlideTeam product in Powerpoint, and go to

- Design ( On the top bar) -> Page Setup -> and select "On-screen Show (16:9)” in the drop down for "Slides Sized for".

- The slide or theme will change to widescreen, and all graphics will adjust automatically. You can similarly convert our content to any other desired screen aspect ratio.

Compatible With Google Slides

Get This In WideScreen

You must be logged in to download this presentation.

PowerPoint presentation slides

Presenting Training Deck on Kaizen as Operational Strategy. This deck comprises of 80 slides. Each slide is well crafted and designed by our PowerPoint experts. This PPT presentation is thoroughly researched by the experts, and every slide consists of appropriate content. All slides are customizable. You can add or delete the content as per your need. Not just this, you can also make the required changes in the charts and graphs. Download this professionally designed business presentation, add your content, and present it with confidence.

People who downloaded this PowerPoint presentation also viewed the following :

Content of this Powerpoint Presentation

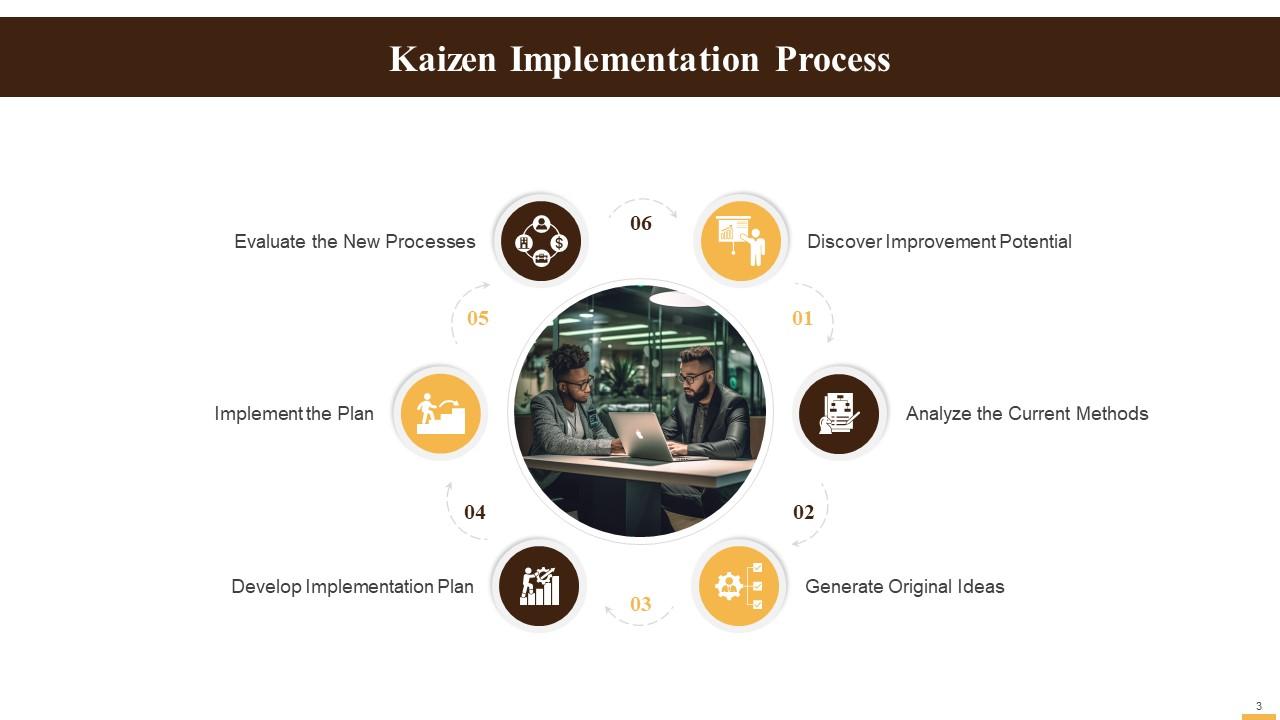

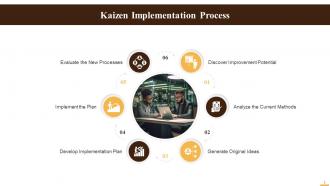

Slide 3

This slide illustrates steps in Kaizen implementation process such as discover improvement potential, analyze current methods, generate original ideas, develop implementation plan, implement the plan, and evaluate new methods.

Instructor’s Notes:

Steps for successful Kaizen implementation process are:

- Discover Improvement Potential: Identify waste and improvement potential around work area

- Analyze Current Methods: Analyze current methods of work-related processes

- Generate Original Ideas: Stimulate original ideas and synthesize solutions using multiple Kaizen techniques

- Develop Implementation Plan: Have an implementation plan for free communication and to track progress

- Implement Plan: Implement Kaizen with a positive and open attitude to embrace the change

- Evaluate New Methods: Evaluate results of new methods used for continuous improvement

Slide 4

This slide provides information about the Kaizen implementation process step that is used to discover improvement potential. It illustrates that employees should have a continuous improvement and waste elimination mindset to be successful.

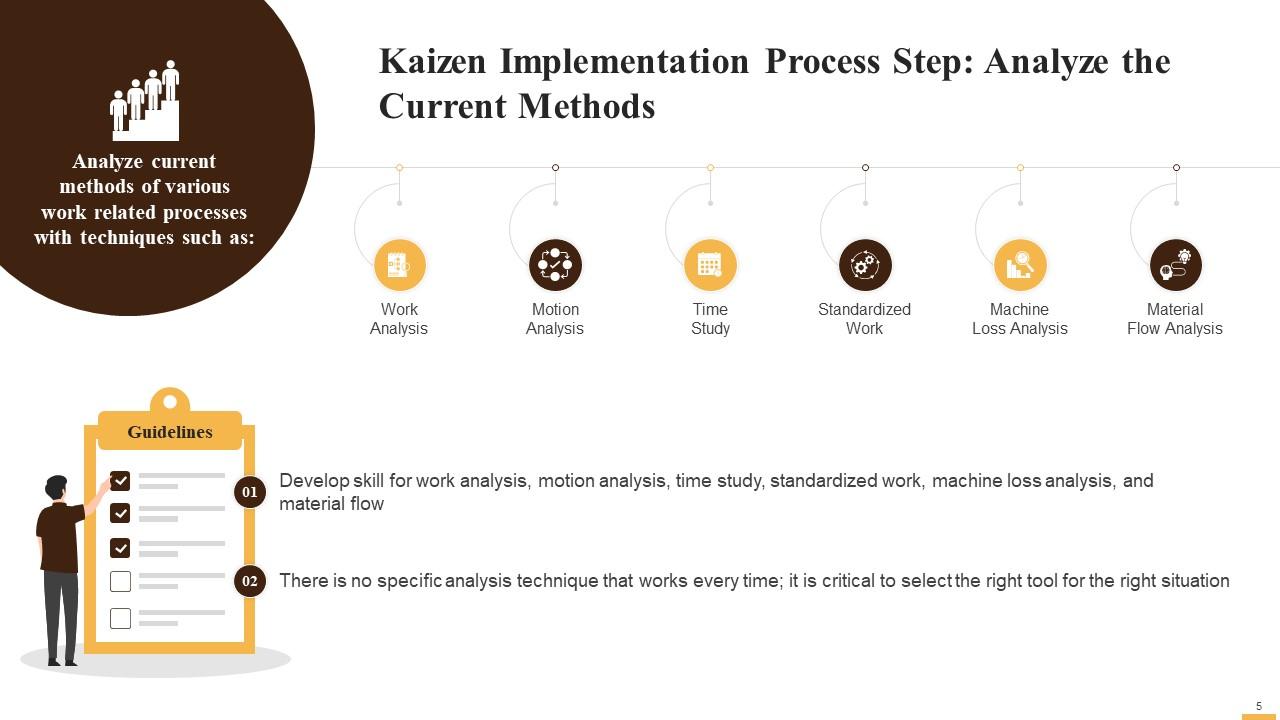

Slide 5

This slide provides information about the Kaizen implementation process step of analyzing the current methods. It emphasizes that it is essential to develop skill such as work analysis, motion analysis, time study, standardized work, machine loss analysis, and material flow to analyze current business processes for improved efficiency.

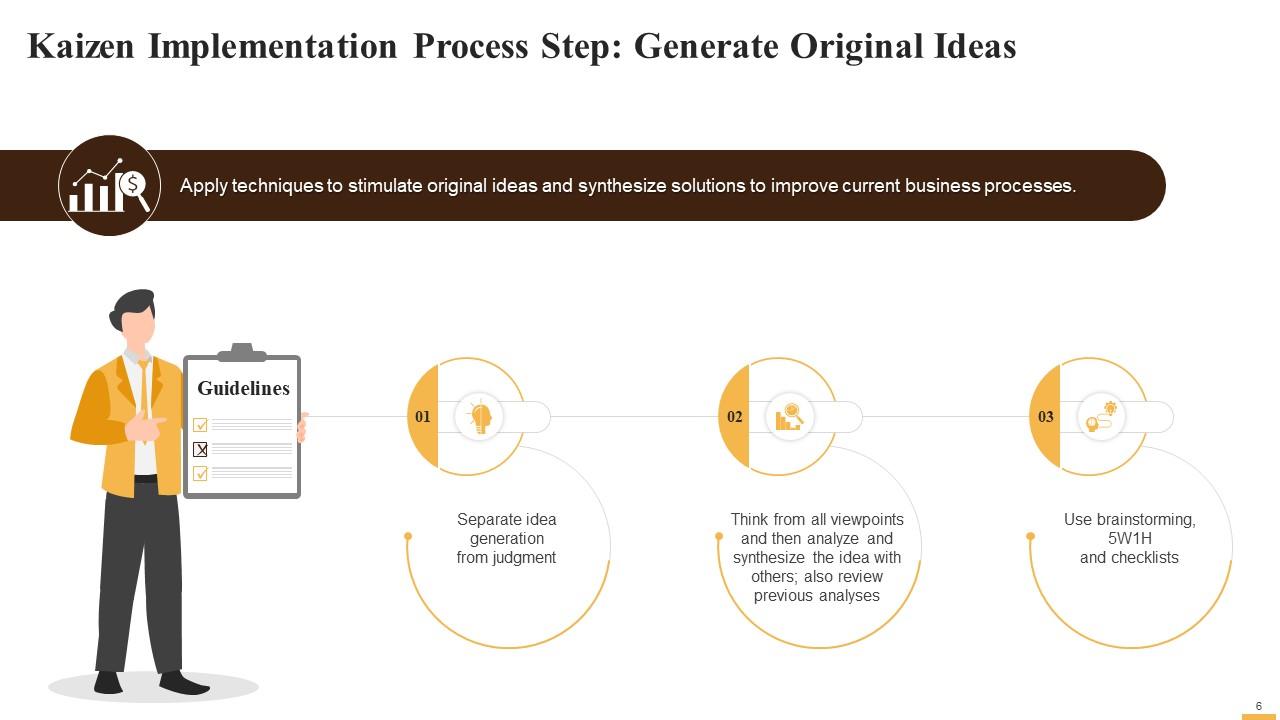

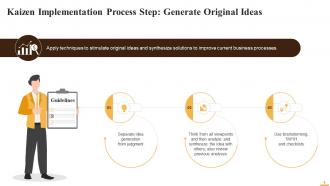

Slide 6

This slide provides information on the Kaizen implementation process step to generate original ideas. It accentuates conscious development of process improvement ideas such as brainstorming, 5W1H, and checklists.

Slide 7

This slide provides information on the guidelines for developing the implementation plan step of the Kaizen process. It highlights that the execution plan must have a tasks list, a well-defined employee’s role, and task completion dates.

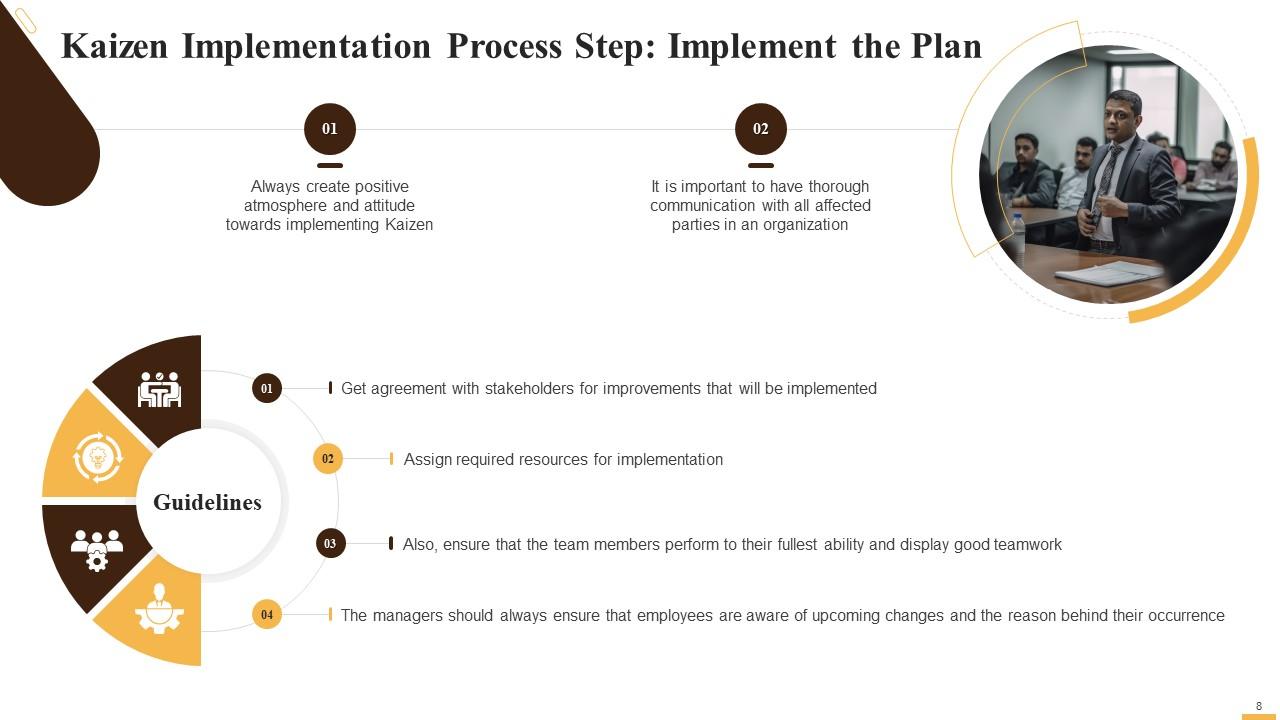

Slide 8

This slide provides information about the Kaizen implementation process step to toward actualization of the plan. The most important guideline is that managers should always ensure that employees are aware of upcoming changes and why they have occurred.

Slide 9

This slide provides information on the Kaizen implementation process step evaluate the new process. It also highlights that if the process used for improvement is ineffective, then it is advised to revisit the analysis and find a new approach that could result in positive change.

Slide 10

This slide showcases the roadmap for the Kaizen execution process in the organization to achieve the objective of continuous improvement. It includes steps, associated activities, and a timeline. The major steps listed are: discover improvement potential, analyze current methods, generate original ideas, develop an implementation plan, implement the plan, and evaluate the new process.

Slide 11

This slide showcases challenges faced while implementing Kaizen. These are that Kaizen is perceived as a short-term project; lack of adequate resources for its implementation; miscalculation in goal setting; insufficient management support; internal and external resistance; lack of training on Kaizen, and inconsistent efforts.

Challenges to Kaizen implementation are:

Kaizen is Perceived as Short-Term Project:

- It is important for employees to understand the concept of Kaizen, which requires time

- The issue with implementation is that organizations often expect quick improvement results in a short time; when this does not happen, then Kaizen is written off as a failure

- The benefits of implementing Kaizen usually appear, first, on a small scale, on a small scale before it propagates throughout the organization

- Toyota started the production of cars which were considered undesirable and low quality, but with the implementation of Kaizen, it turned out to be the poster child for quality

Lack of Adequate Resources:

- Another common challenge to Kaizen implementation is the lack of access to resources

- Lack of resources that hinder the continuous improvement process is manifested in an all-inclusive budge. Then, organizations are also able to allocate special resources for Kaizen training, Kaizen software solution, and manufacturing hardware

- Among all of these resources, the lack of Kaizen software is the most common and challenging resources that plagues adoption of the technique

- It is important to track and monitor manufacturing performance to ensure organizations overcome this resistance to allocate resources

Miscalculations in Goal Setting:

- Poor planning of goals can turn out to be counterproductive to the improvement process

- The prime goal for Kaizen implementation is to improve important metrics of all aspects of businesses, from the purchase of raw material to the delivery of finished products to the customer

- Once the problem has been identified, try to find the root cause of the issue with an in-depth analysis

Insufficient Management Support:

- It is important for the management to share their thoughts on implementing Kaizen with the employees

- The purpose of using Kaizen is that everyone should be improving everything and not just a group of people making improvements in silos

Internal and External Resistance:

- It is possible that both the employees and the management fail to clearly understand the objectives and technicalities of the continuous improvement process

- It could lead to covert and overt resistance in the organization

- Resistance to Kaizen implementation can come from floor workers to employees in the same or other departments

- The resistance could be due to threats to employees' status and positions in the organization

- To overcome such issues, it is important that employees are reassured that the improvement processes are meant to improve production and make work easier for the employees

Lack of Training on Kaizen:

- In order to make Kaizen successful, it is essential to give proper training to employees so that they can thoroughly learn how to implement the tools and concept

Inconsistent Efforts:

- The most crucial aspect of Kaizen improvement is continuity

- Manufacturing firms achieve progress through the Kaizen implementation process, but it is also important for them to continue with the process with consistency even after the desired results are achieved

- If they fail to do so, then they may risk regression to older, inefficient ways of working

Slide 12

This slide provides information on Kaizen implementation challenge, which is that it is perceived as a short-term project. It also explains that it is important for employees to understand the concept of Kaizen, which requires time.

Slide 13

This slide provides information on lack of adequate resources, as a major challenge to Kaizen implementation.

Slide 14

This slide provides information on miscalculations in goal-setting, a challenge for the Kaizen implementation process. It illustrates that poor planning of goals can turn out to be counterproductive to the improvement process.

Slide 15

This slide provides information on insufficient management support, a challenge for the Kaizen implementation. It also highlights that it is vital for the management to share their thoughts on implementing Kaizen with its employees.

Slide 16

This slide provides information on internal and external resistance, a challenge for the Kaizen implementation process. It also exemplifies that both the employees and regulatory bodies may fail to understand the objectives and technicalities of this continuous improvement process, another cause for resistance.

Slide 17

This slide provides information on the lack of training provided on Kaizen as a challenge for its implementation. It also explains that to make Kaizen successful, it is essential to give employees proper training so they can use and implement the tools and concepts.

Slide 18

This slide provides information on inconsistent efforts as a challenge for Kaizen implementation.

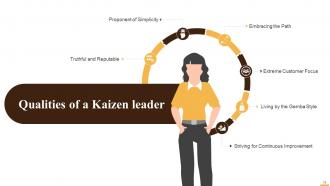

Slide 19

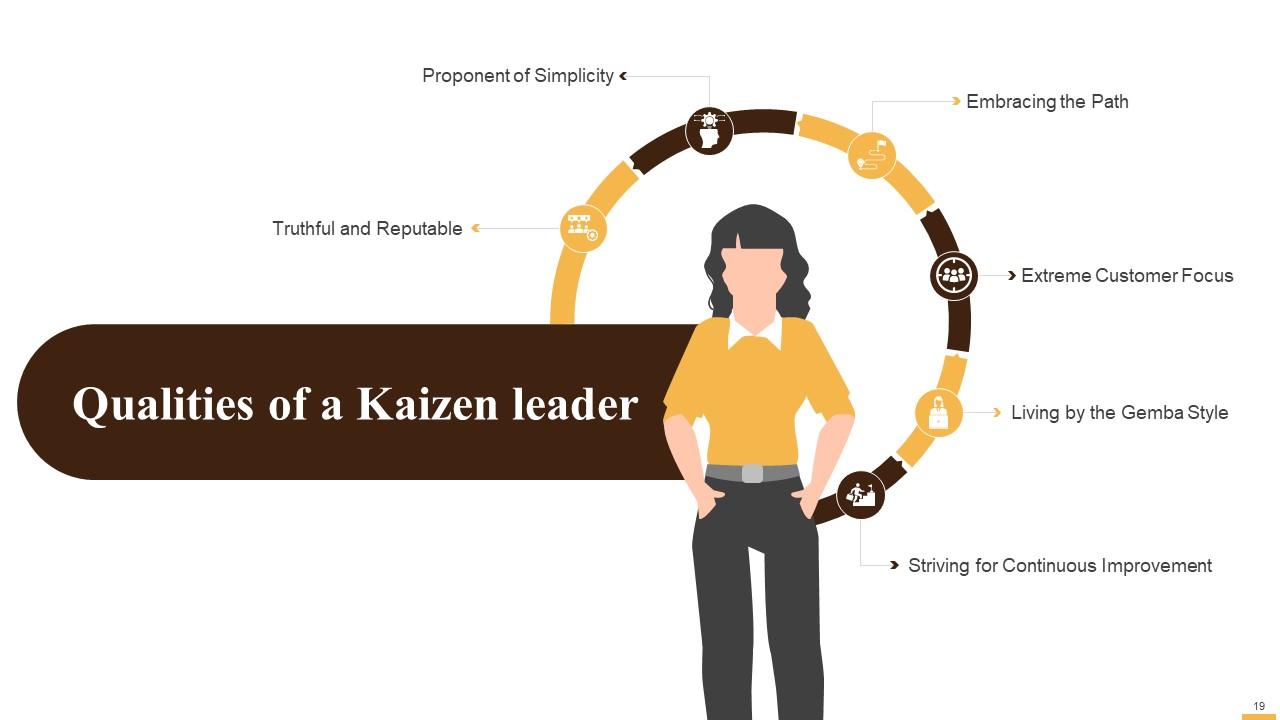

This slide highlights the qualities of a Kaizen leader. Some of these are embracing the path, extreme customer focus, striving for continuous improvement, living by the Gemba style, proponent of simplicity, and being reputable and truthful.

Instructor’s Notes

The qualities of a Kaizen leader are:

- Striving for Continuous Improvement: Every Kaizen leader must believe that everything can be made better, and must constantly strive for perfection. Leaders should never think that they know everything; instead, they should have healthy curiosity about various work possibilities and alternatives, which in turn accelerates more and more learning

- Living by the Gemba Style: Gemba is a Japanese word that means "a place where value is built." A Kaizen leader needs to identify those areas and interact more with the real touch-points. Here, they can actively engage with the people closest to the customer instead of simply relying on third-party reports and only going to the workplace when there is a problem

- Extreme Customer Focus: An intense customer focus and an understanding of what they value will lead to improving the area of focus. A problem-solving culture where problems are recognized as such, and readily solved combined with customer value will make it even more simpler to meet or exceed customer expectations

- Embracing the Path: Kaizen is a journey and not a short-term program. It should be considered an integral part of the overall business strategy by inculcating long-term thinking and sustainable mindset of the Kaizen leader. Moreover, these leaders should be able to deeply reflect on their own mistakes and strive to look for opportunities toward perfection

- Proponent of Simplicity: A complex organizational structure makes it difficult to ensure maximum efficiency, and that is why simplicity is seen as a virtue. An effective Kaizen leader is able to identify wastages and non-valuable activities which do not solve the purpose of the organization; they eliminate those activities

- Reputable and Truthful: Since the primary role of a Kaizen leader is to be a coach, it is quite important that he is genuine in his words and honorable in his deeds. He should be capable of leading by example, and that can only be done if he acts with high integrity

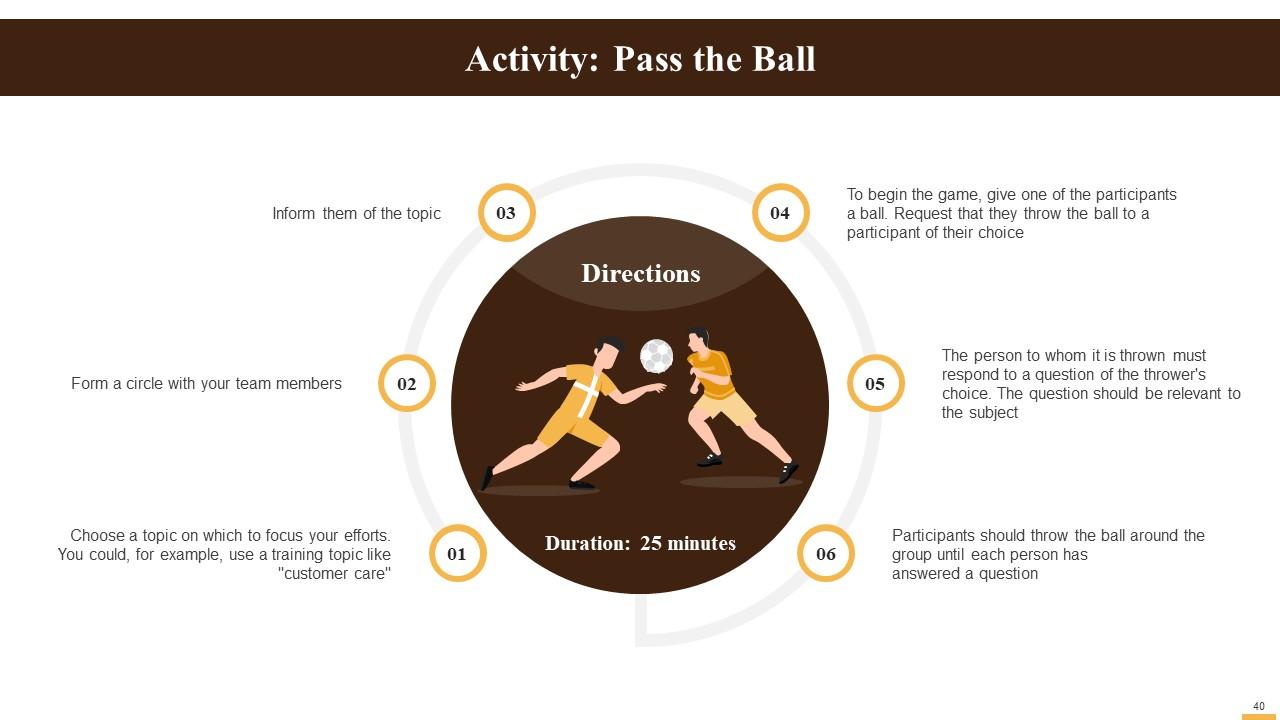

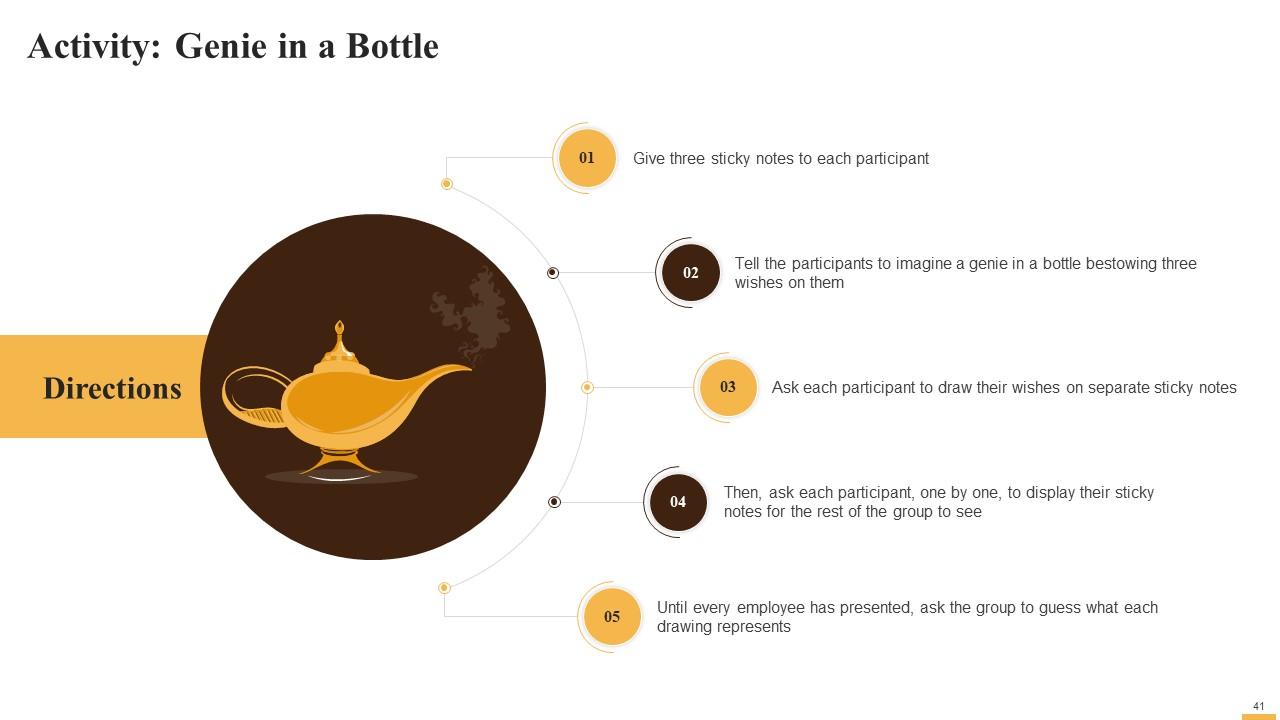

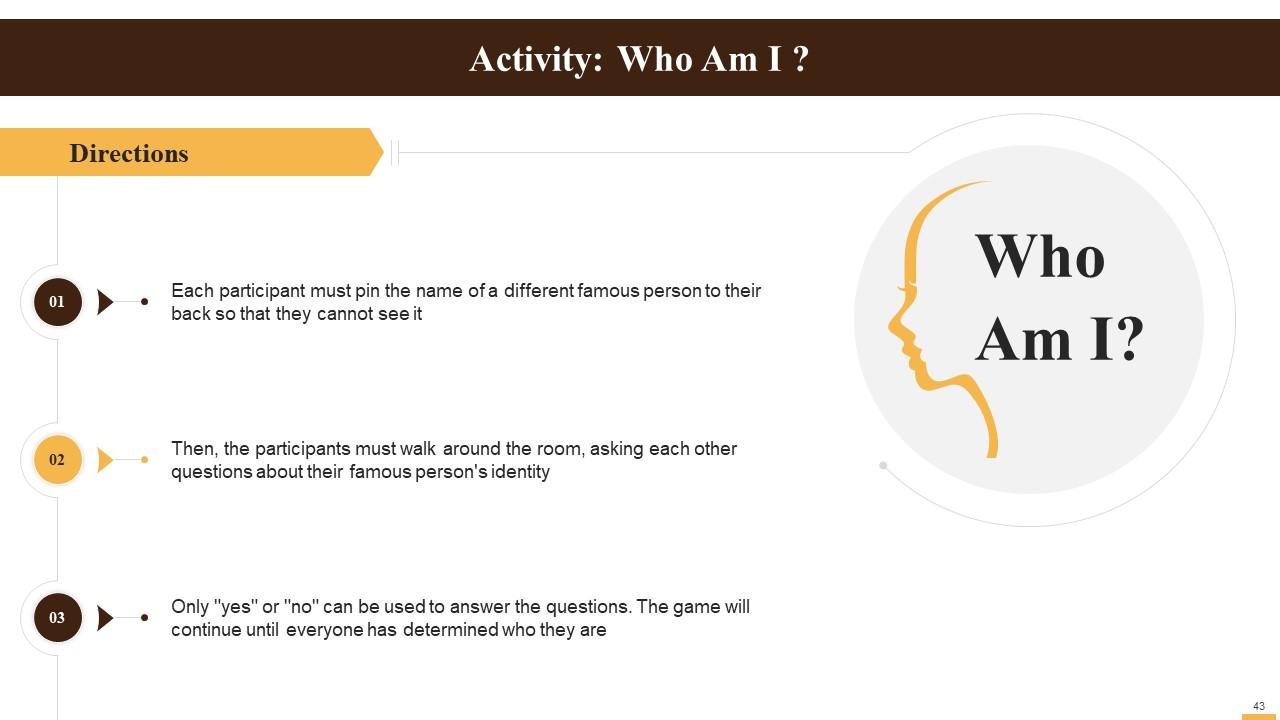

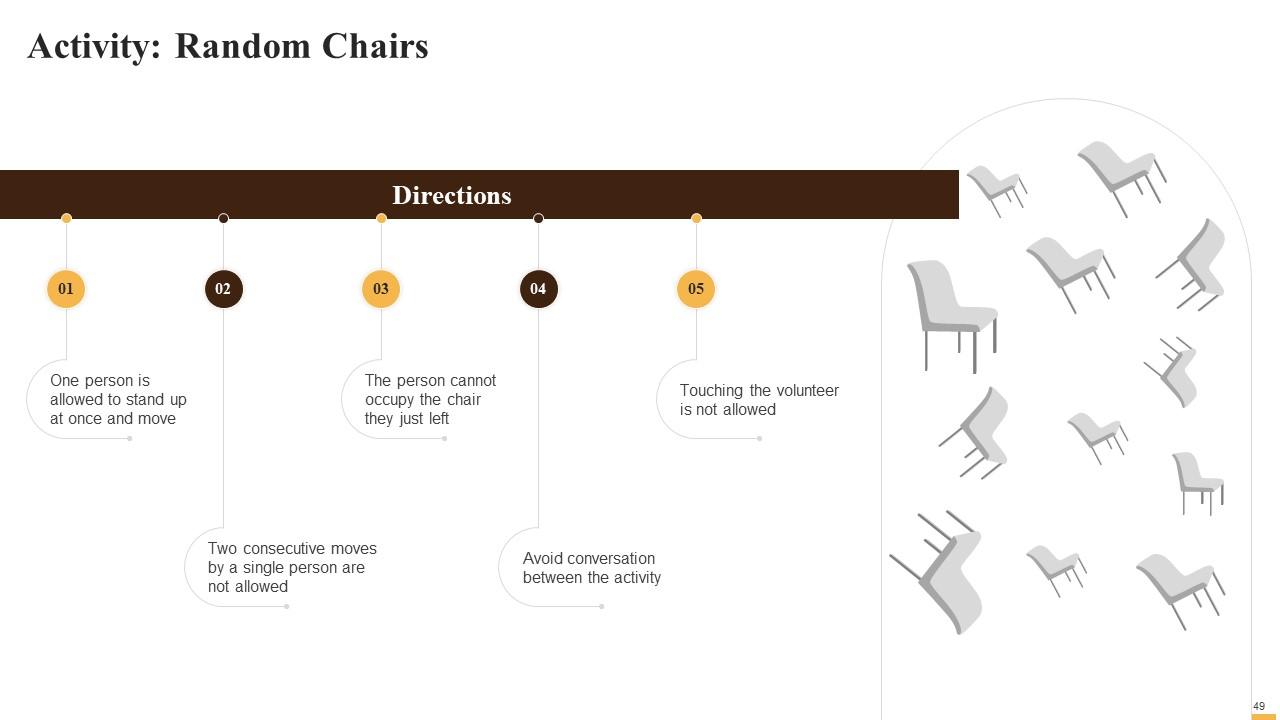

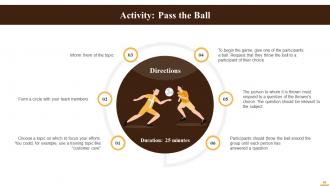

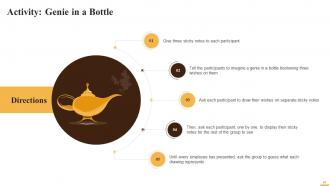

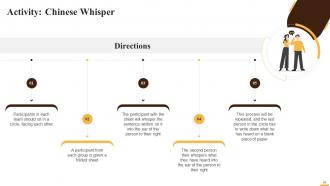

Slide 34 to 49

These slides contain energizer activities that a trainer can employ to make the training session interactive and engage the audience.

Slide 50 to 77

These slides contain a training proposal covering what the company providing corporate training can accomplish for prospective clients.

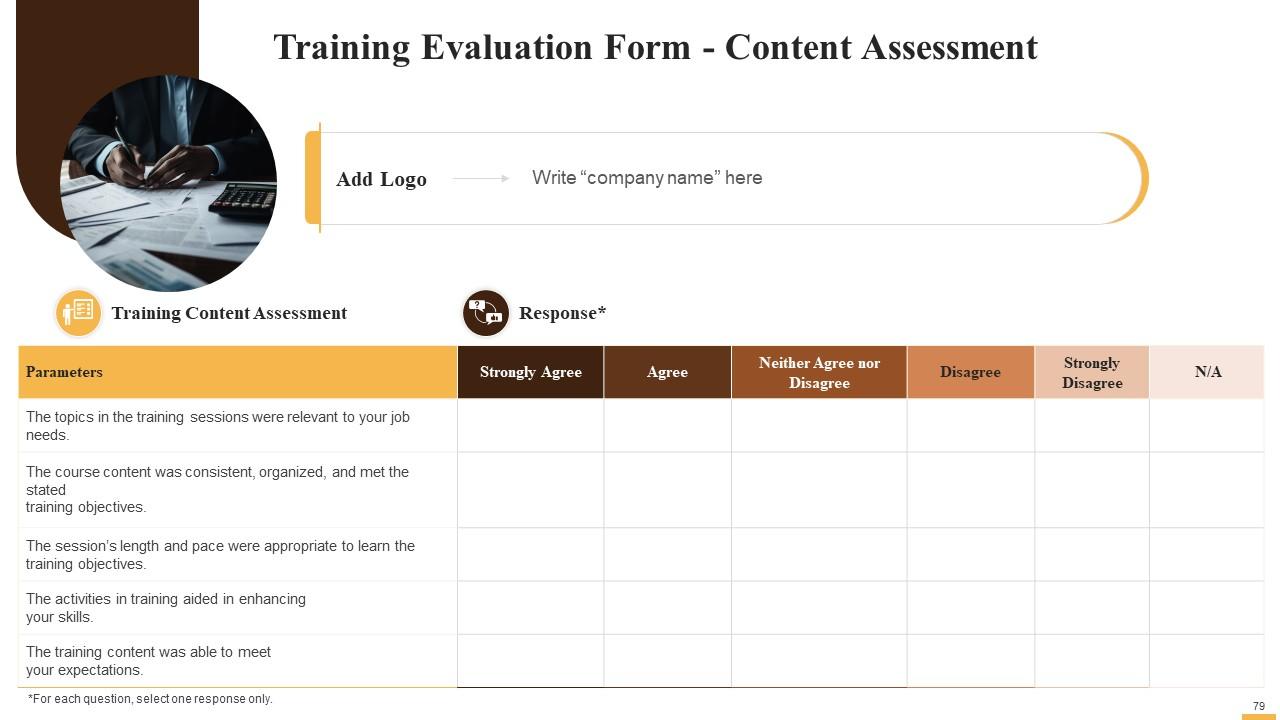

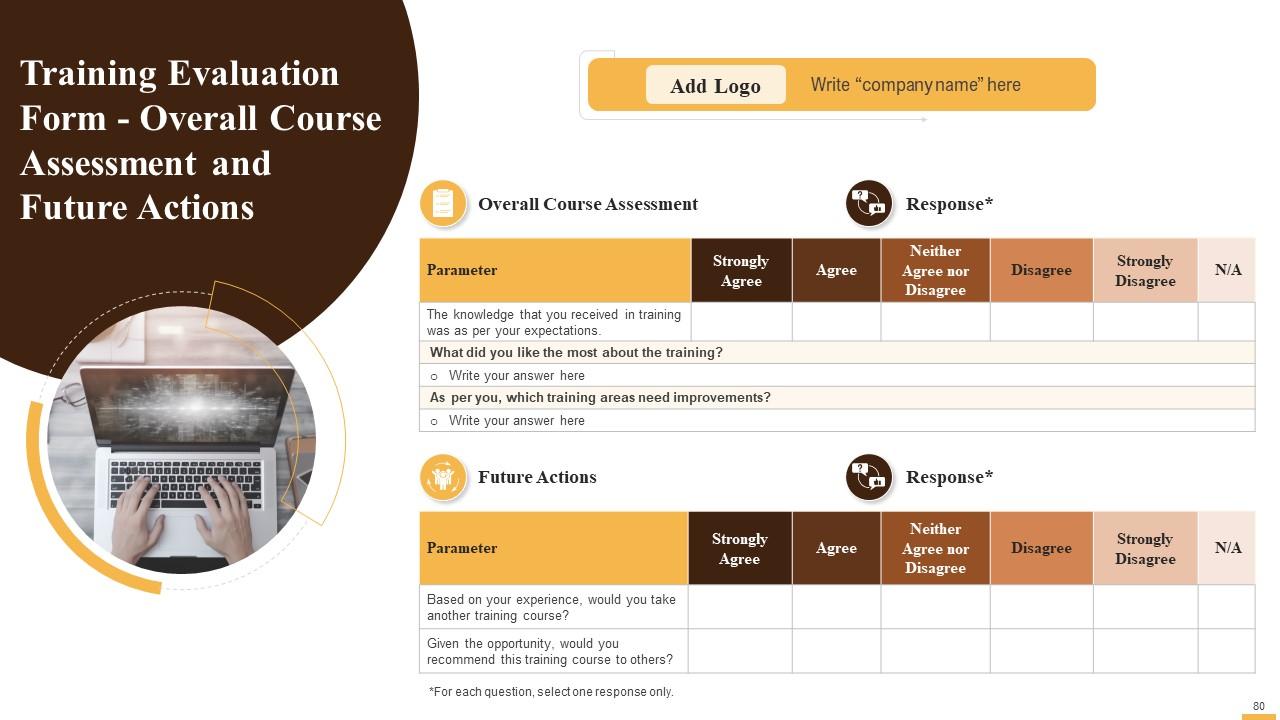

Slide 78 to 80

These slides include a training evaluation form for the instructor, content, and course assessment to assess the effectiveness of the coaching program.

Kaizen as Operational Strategy Training Ppt with all 89 slides:

Use our Kaizen as Operational Strategy Training Ppt to effectively help you save your valuable time. They are readymade to fit into any presentation structure.

-

Great quality product.

-

Presentation Design is very nice, good work with the content as well.