Kaizen Tools and Techniques Training Ppt

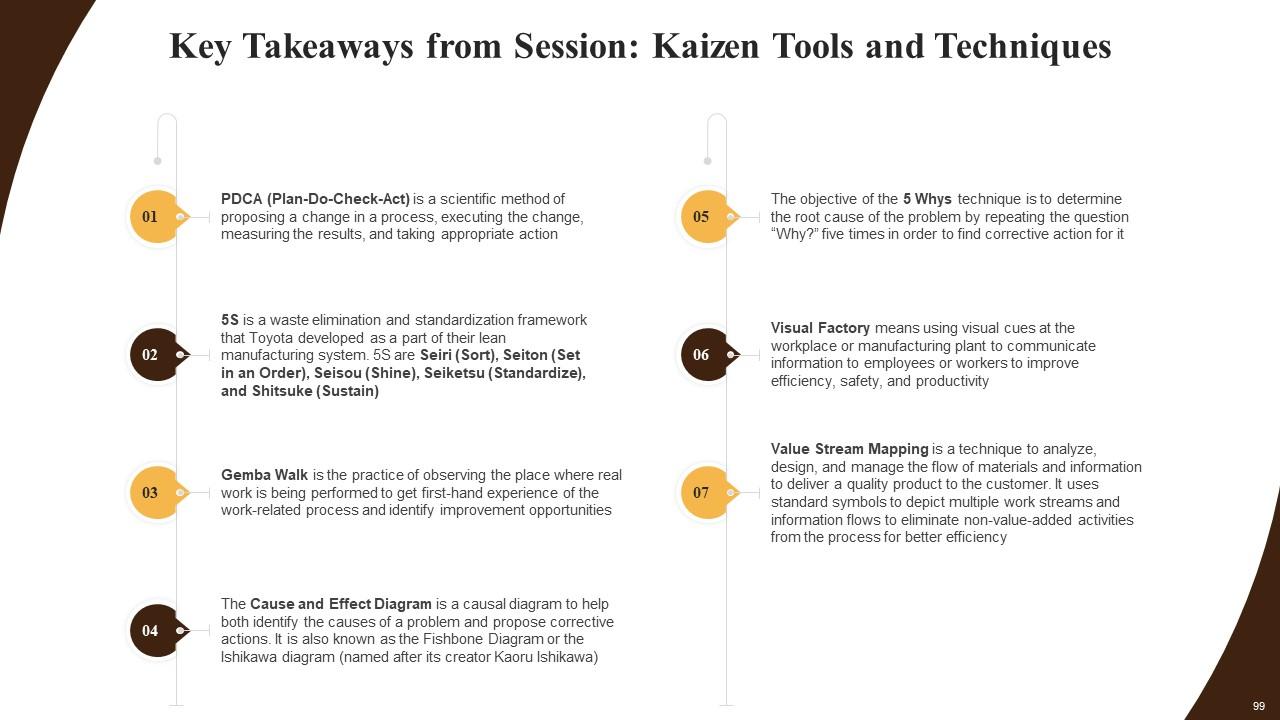

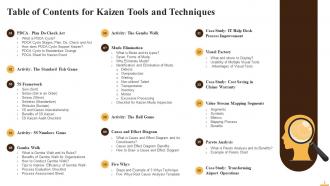

The PPT Training Module on Kaizen Tools and Techniques covers a wide array of methods, each detailed in dedicated sections, making it an invaluable guide for businesses seeking to implement continuous improvement strategies. The Deck begins with the PDCA Plan Do Check Act cycle, explaining its stages and how it supports the Kaizen process. Next, it delves into the 5S Framework, a fundamental pillar of Kaizen. It breaks down the components Seiri Sort, Seiton Set in Order, Seisou Shine, Seiketsu Standardize, and Shitsuke Sustain. Gemba Walk, another key Kaizen tool, is explained in detail, covering its rules, benefits, and tips for conducting an effective Gemba Walk. Next, Muda Elimination is covered extensively, explaining the concept of Muda waste, its seven forms, and strategies for identification and elimination. The PowerPoint Deck further introduces approaches such as the Cause and Effect Diagram, Five Whys Technique, Visual Factory, Value Stream Mapping, and Pareto Analysis. The PPT also has Key Takeaways and Discussion Questions related to the topic to make the training session more interactive. The Deck contains PPT slides on About Us, Vision, Mission, Goal, 30 60 90 Days Plan, Timeline, and Training Completion Certificate.

The PPT Training Module on Kaizen Tools and Techniques covers a wide array of methods, each detailed in dedicated sections,..

- Google Slides is a new FREE Presentation software from Google.

- All our content is 100% compatible with Google Slides.

- Just download our designs, and upload them to Google Slides and they will work automatically.

- Amaze your audience with SlideTeam and Google Slides.

-

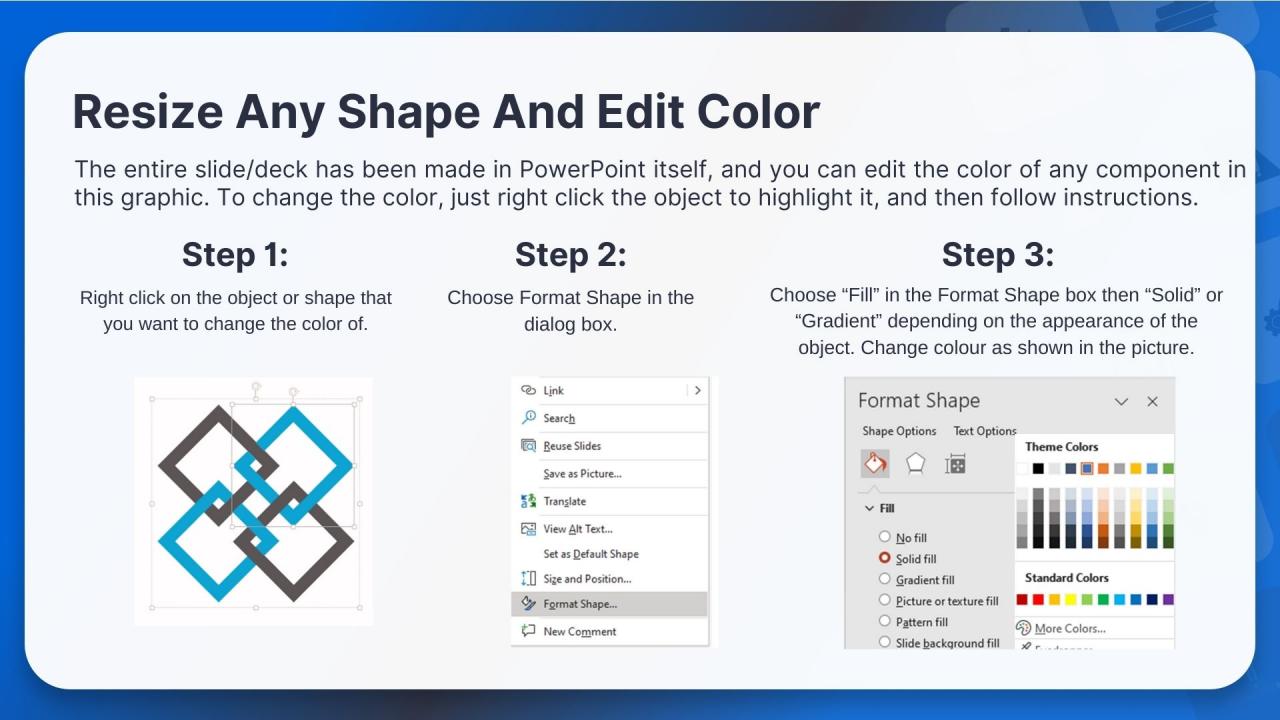

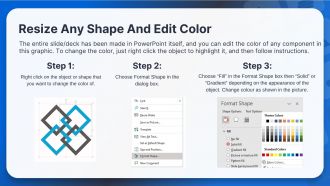

Want Changes to This PPT Slide? Check out our Presentation Design Services

- WideScreen Aspect ratio is becoming a very popular format. When you download this product, the downloaded ZIP will contain this product in both standard and widescreen format.

-

- Some older products that we have may only be in standard format, but they can easily be converted to widescreen.

- To do this, please open the SlideTeam product in Powerpoint, and go to

- Design ( On the top bar) -> Page Setup -> and select "On-screen Show (16:9)” in the drop down for "Slides Sized for".

- The slide or theme will change to widescreen, and all graphics will adjust automatically. You can similarly convert our content to any other desired screen aspect ratio.

Compatible With Google Slides

Get This In WideScreen

You must be logged in to download this presentation.

PowerPoint presentation slides

Presenting Training Deck on Kaizen Tools and Techniques. This deck comprises of 117 slides. Each slide is well crafted and designed by our PowerPoint experts. This PPT presentation is thoroughly researched by the experts, and every slide consists of appropriate content. All slides are customizable. You can add or delete the content as per your need. Not just this, you can also make the required changes in the charts and graphs. Download this professionally designed business presentation, add your content, and present it with confidence.

People who downloaded this PowerPoint presentation also viewed the following :

Content of this Powerpoint Presentation

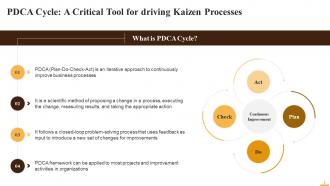

Slide 3

This slide contains information about the PDCA (Plan-Do-Check-Act) approach, which is an iterative method to continuously improve business processes. It also includes details on how the Deming Circle can be applied to most projects and improvement activities in organizations.

Slide 4

This slide visually illustrates the multiple stages in a PDCA cycle, i.e., Plan, Do, Check and Act. It also contains details about what should be performed in each step to successfully achieve rapid and continuous business process changes.

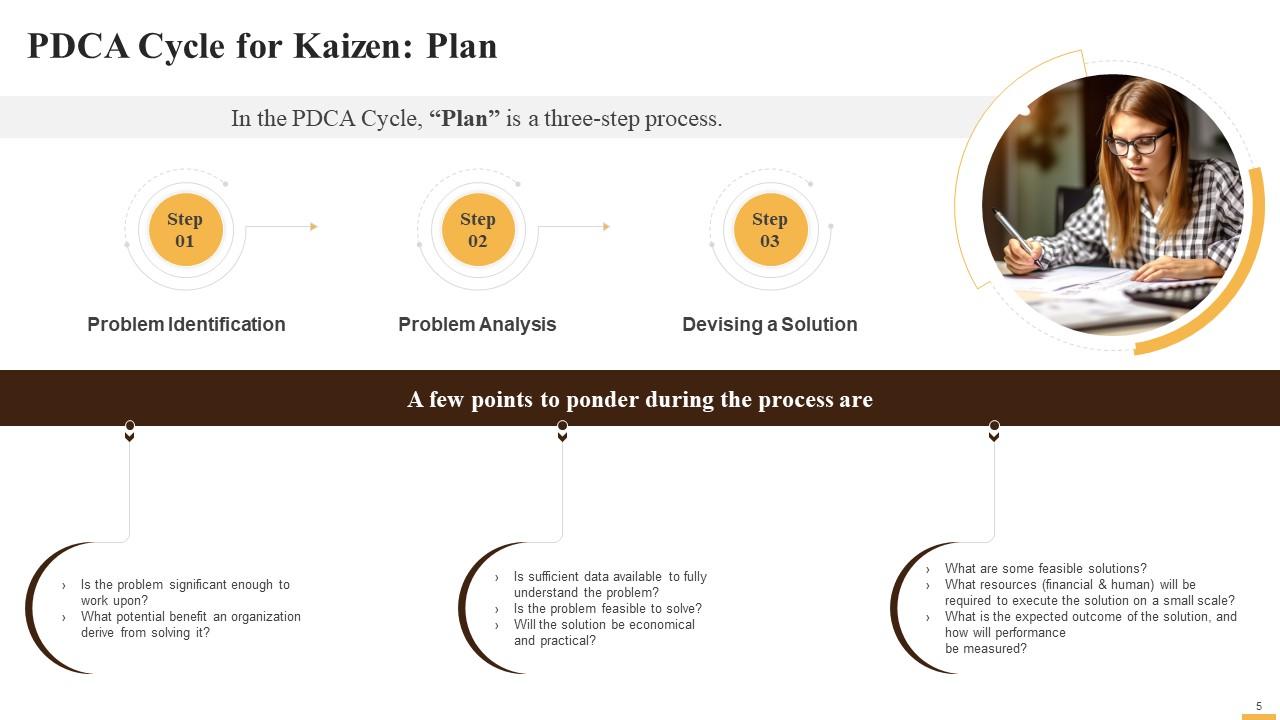

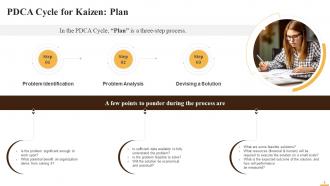

Slide 5

This slide provides information on the plan step in the PDCA cycle. It includes details about the three stages of the plan step: problem identification, problem analysis, and devising a solution.

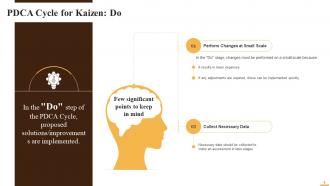

Slide 6

This slide contains details of the "Do" stage of the PDCA cycle. It provides information on critical actions that should be performed in this step of the Plan, Do, Act, and Check technique i.e., execute changes on a small scale and collect necessary data.

Slide 7

This slide lists questions that can be used for evaluation in the Check Stage of the PDCA (Plan, Do, Check, and Act) Cycle. The process is meant for continuous improvement of business process on a small scale.

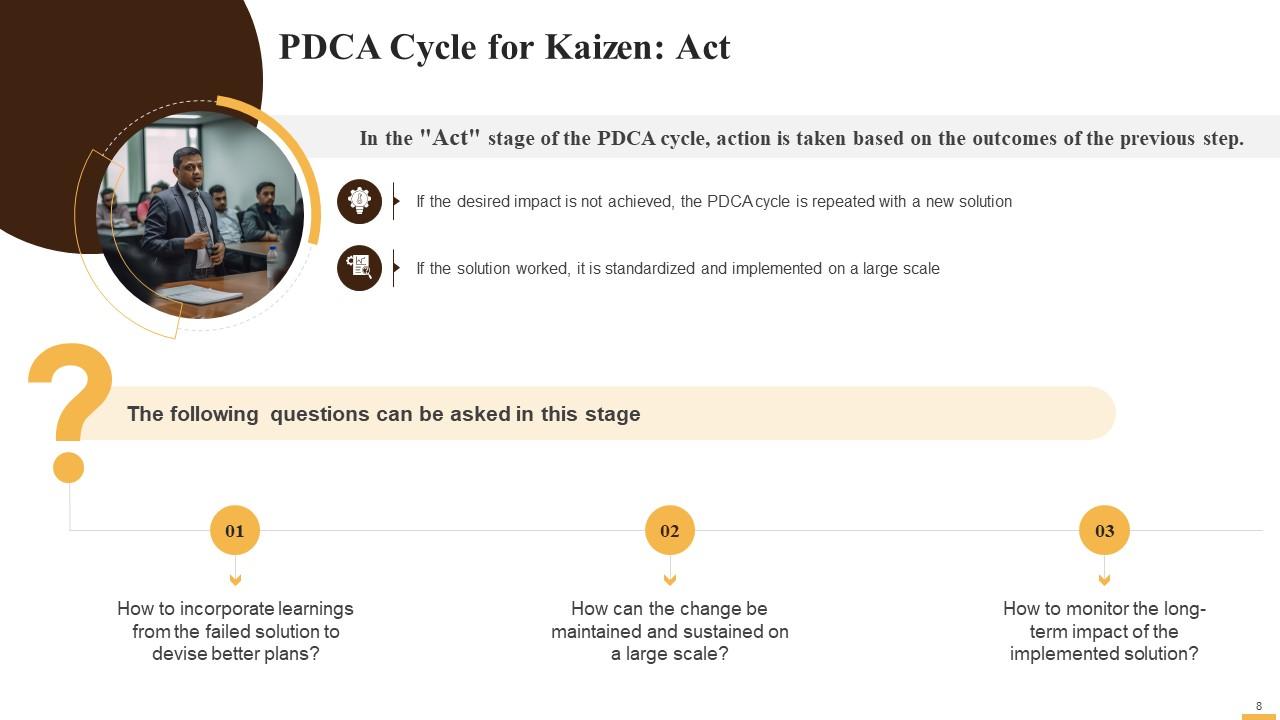

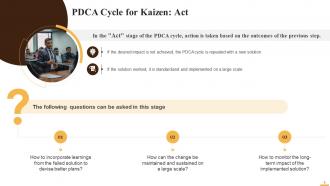

Slide 8

This slide provides information about the “Act” step in the PDCA Cycle. It contains details on actions to take in this stage, i.e., if the desired impact is not achieved, the PDCA cycle is repeated with a new solution. If the solution works, it is standardized and implemented on a large scale.

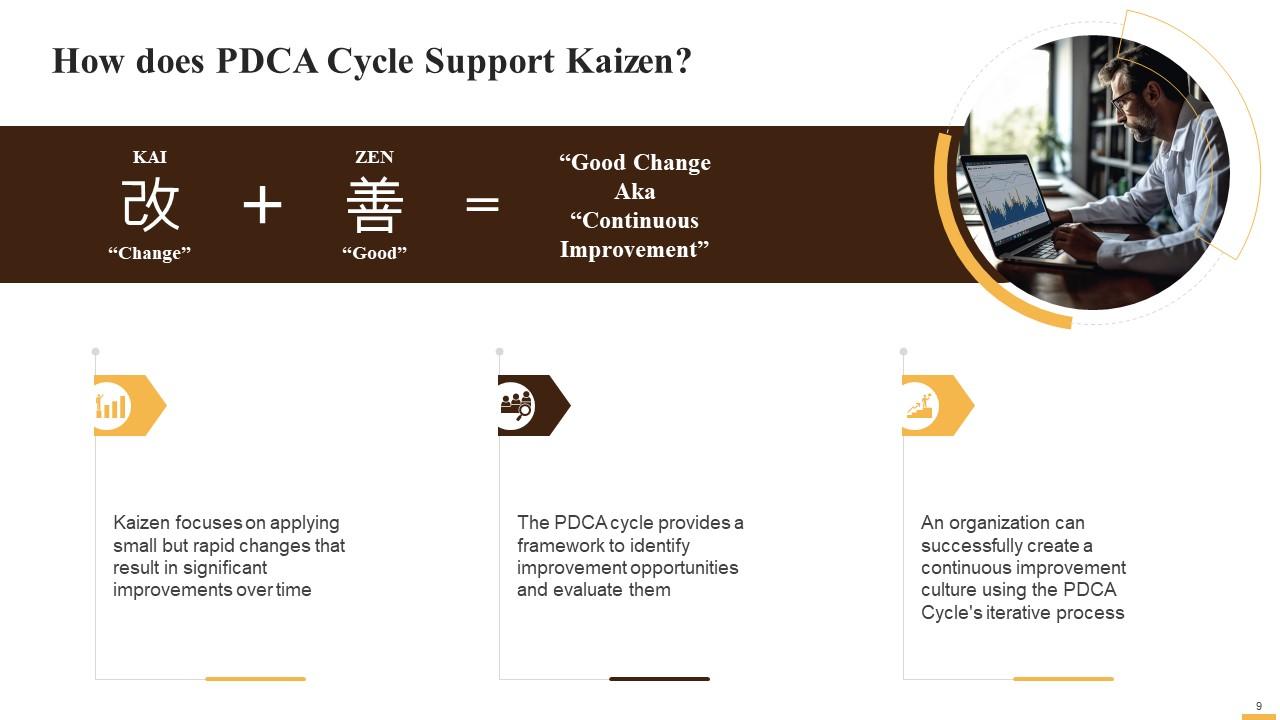

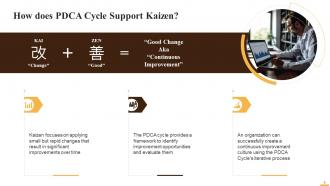

Slide 9

This slide showcases how the PDCA (Plan, Do, Check, and Act) cycle provides a framework to identify improvement opportunities and evaluate these objectively to achieve the core objective of Kaizen.

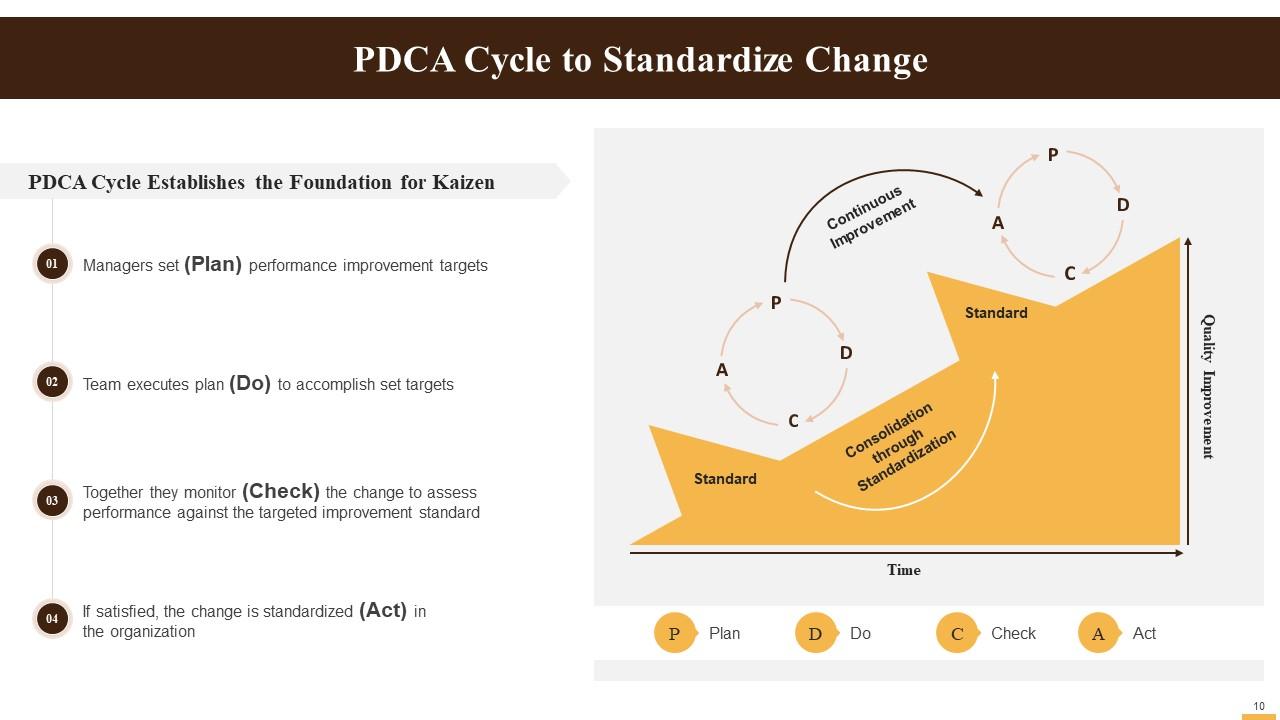

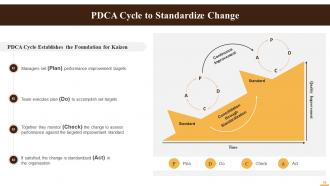

Slide 10

This slide illustrates that the PDCA (Plan, Do, Check, and Act) cycle establishes a foundation to create Kaizen culture across organizations.

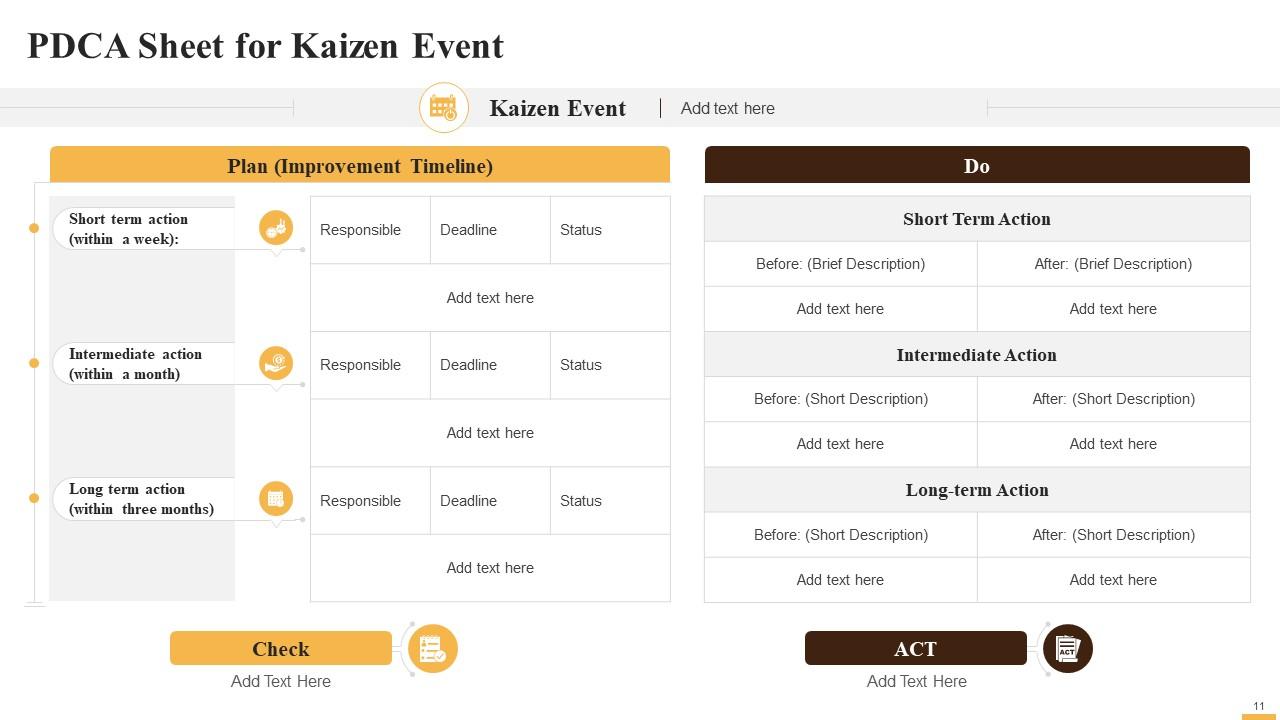

Slide 11

This slide presents a PDCA (Plan-Do-Check-Act) worksheet for a Kaizen event. It can be used to plan, execute and track short (within a week), intermediate (within a month), and long-term (within three month) change initiatives.

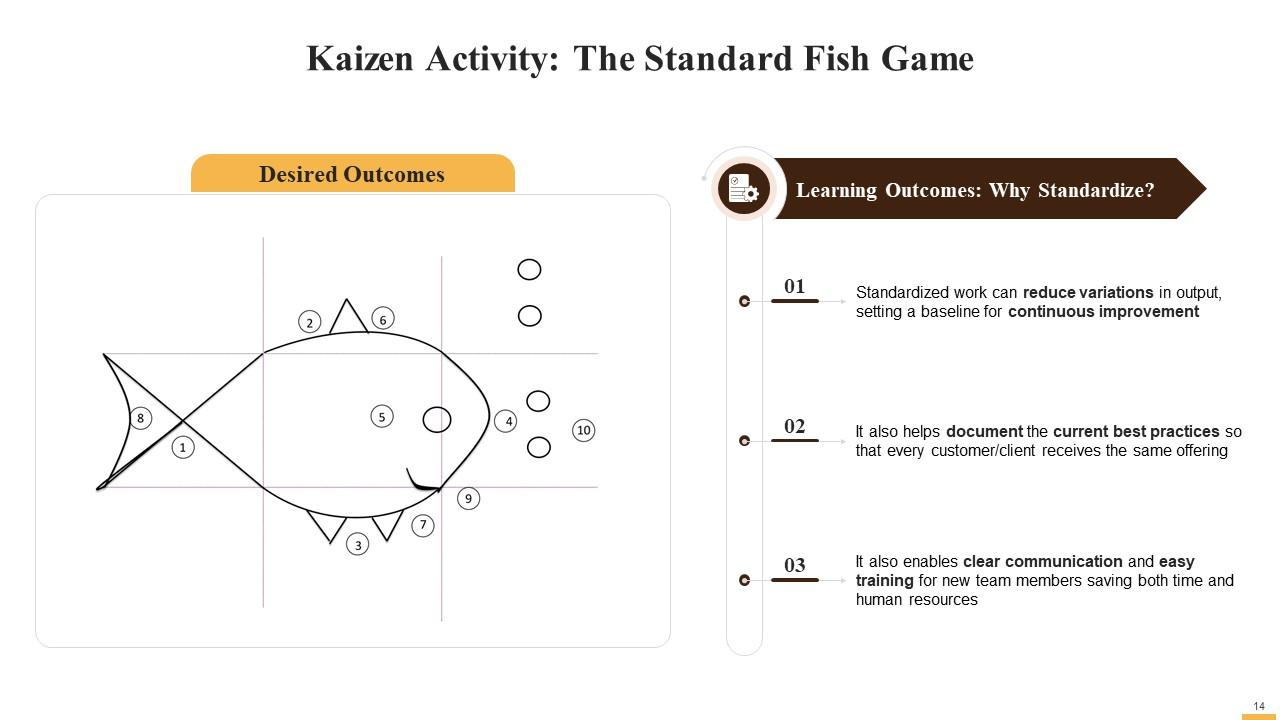

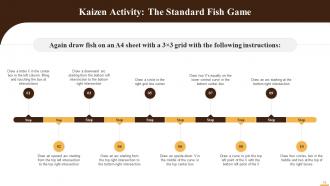

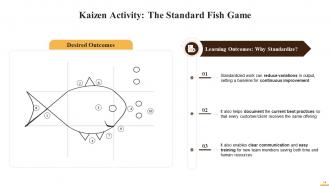

Slide 12 to 14

These slide provide information about the steps and learning outcomes of ‘The Standard Fish Game’ exercise for a Kaizen training session.

Slide 15

This slide contains information about the 5S methodology i.e., seiri (sort), seiton (set in order), seisou (shine), seiketsu (standardize), and shitsuke (sustain). 5S is a structured way to design and maintain an organized, clean, safe, and high-performing work environment

Slide 16

This slide contains details regarding the sorting phase of the 5S framework, which is inspecting all items in the workplace and keeping only those that are required.

Slide 17

This slide includes information about the techniques to deploy to complete the “sorting” phase of 5S at the workplace. It also contains details about the Red Tag, a popular labeling tool used in the “sorting” stage.

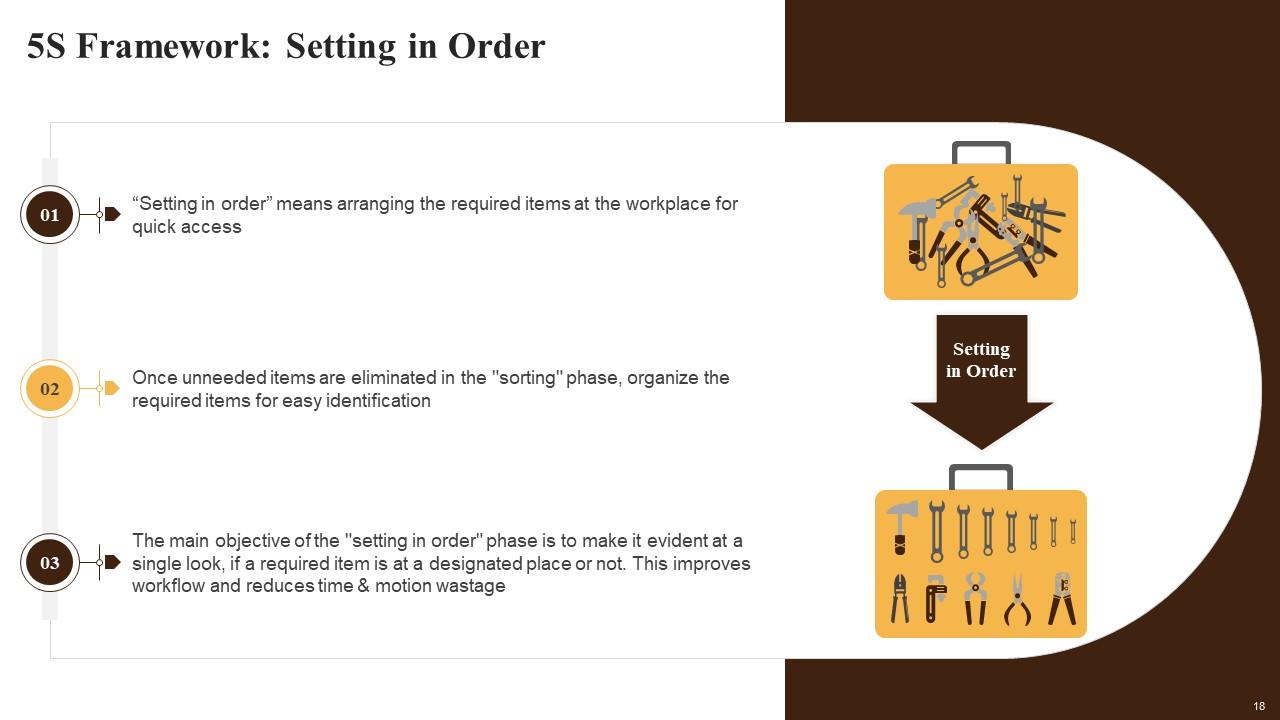

Slide 18

This slide contains details regarding the setting in order phase of the 5S framework. The objective of the "setting in order" phase is to make it evident, if a required item is at a designated place or not, as it will improve workflow and reduces time & motion wastage.

Slide 19

This slide lists multiple approaches that can be deployed to set items in order at the workplace as per the 5S methodology. The major techniques are specific positions, install storage units, use labels & color-coding, deploy closed storage system, and outline areas.

Slide 20

This slide provides information about the shining phase in the 5S methodology. It includes details on objectives of the shining stage i.e. abnormalities identification and ownership development.

Slide 21

This slide highlights approaches for the shining step of the 5S methodology. The primary technique is identifying and eliminating causes of dirt, contamination, and clutter at the workplace.

Slide 22

This slide provides information about the standardizing phase in the 5S framework. In 5S, standardizing means establishing procedures and schedules to ensure consistency in implementing the first three ‘5S’ practices i.e., sorting, setting in order, and shining.

Slide 23

This slide provides information about approaches such as using visual elements, communicating responsibilities, and conducting audits to standardize 5S Principles at the workplace.

Slide 24

This slide covers the concept of sustaining in 5S methodology, i.e., the disciplined application of the first four ‘S’ principles: sorting, setting in order, shining and standardizing.

Slide 25

This slide list techniques to sustain gains from the 5S program at the workplace, such as using posters and signs to highlight the benefits of 5S, involving each employee and making them accountable, etc.

Slide 26

This slide provides information about the relationship between 5S and Kaizen. It highlights that a Kaizen 5S workplace showcases that an organization values and implements a continuous improvement culture.

Slide 27

This slide highlights the advantages that 5S Kaizen offers to organizations, such as increased productivity and efficiency, increased workplace safety, reduced waste, effective cost control, and improved employee commitment.

Instructor’s Notes:

- Increased Productivity and Efficiency: 5S framework components make the workplace more organized, resulting in improved productivity and efficiency

- Increased Workplace Safety: Proper storage systems and clutter-free workspace reduces accidents, creating a safe environment

- Reduced Waste: 5S Kaizen ensures waste reduction with the removal of unwanted items/equipment/tools from the workplace

- Effective Cost Control: Embracing the 5S system can significantly reduce direct and indirect costs such as machine replacement, employees' insurance claims, etc.

- Improved Employee Commitment: Since 5S Kaizen implementation requires employees' active participation, it leads to increased engagement and creates a work culture in which employees take pride in their work and contributions

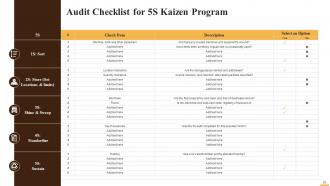

Slide 28

This slide showcases an audit checklist that businesses can use to investigate the effectiveness of the 5S Kaizen Program. It contains details of the checked item and a description of each 5Ss, i.e., sort, set in order, shine, standardize, and sustain.

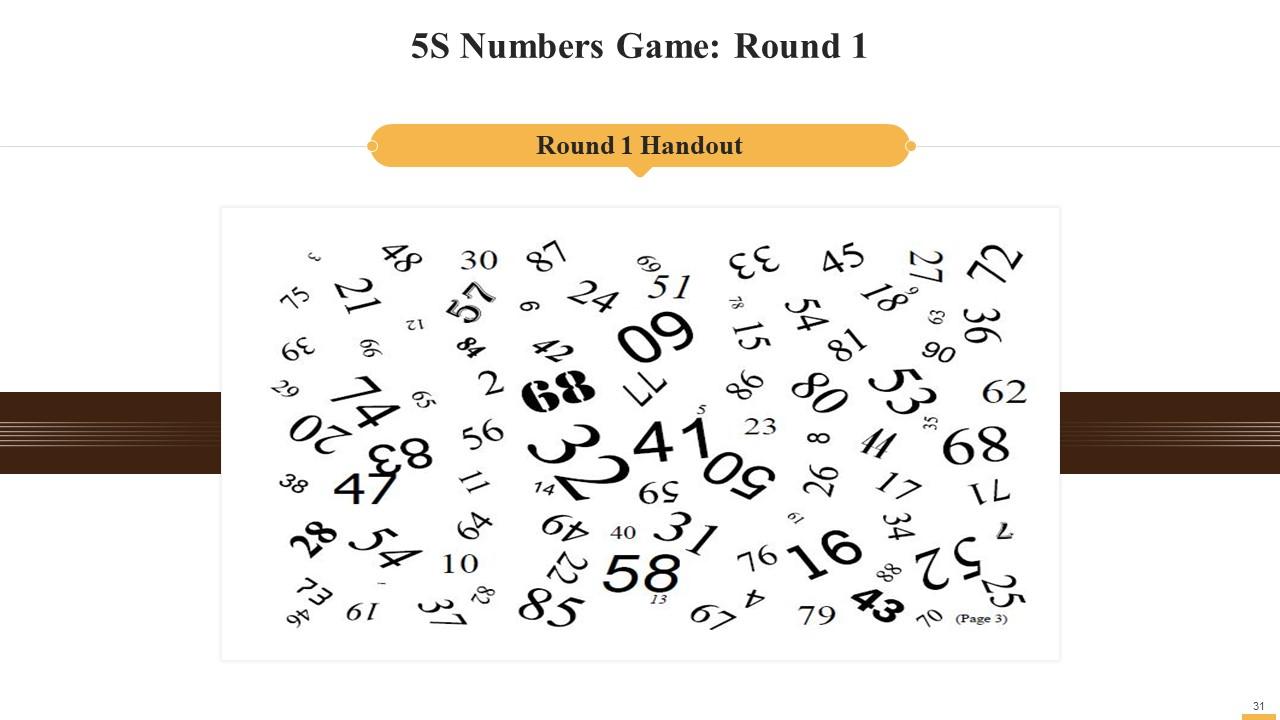

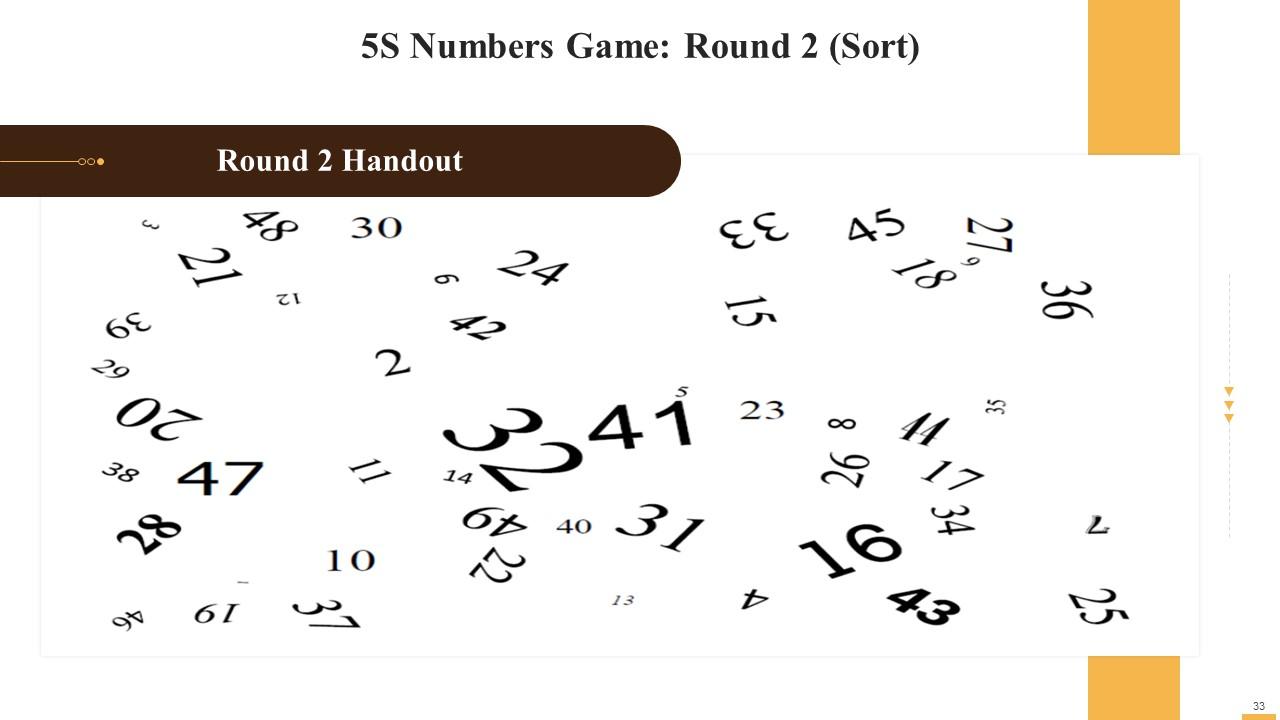

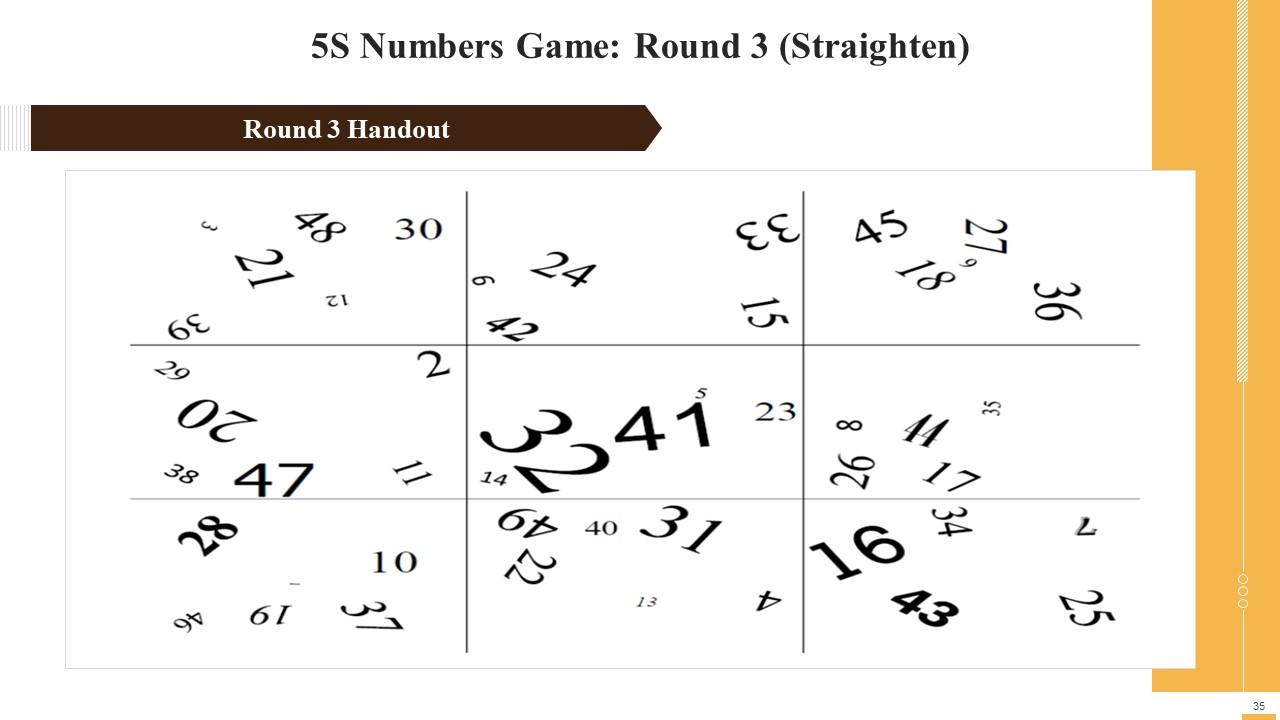

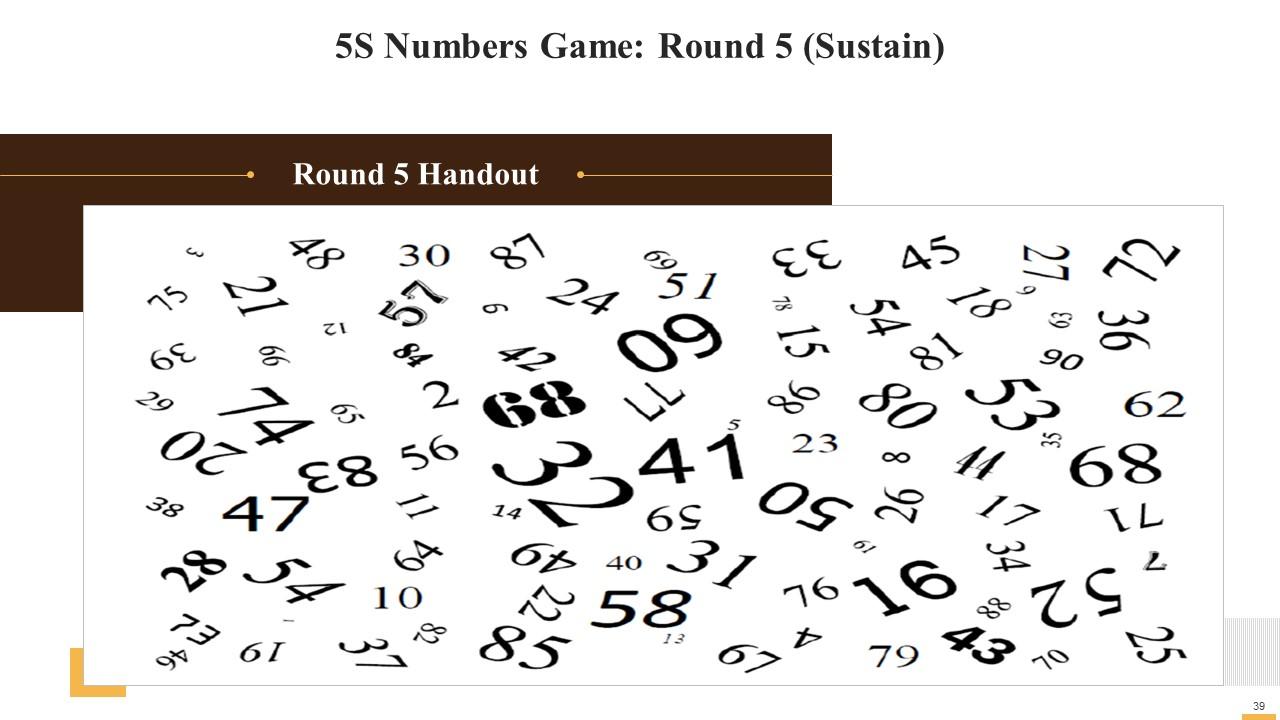

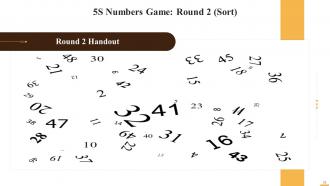

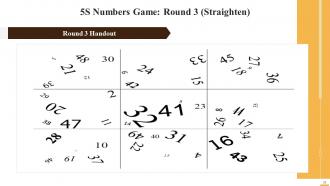

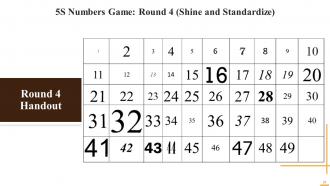

Slide 29 to 39

This slide contains the learning objectives, material required, and instructions to conduct a 5S numbers game for the Kaizen training session.

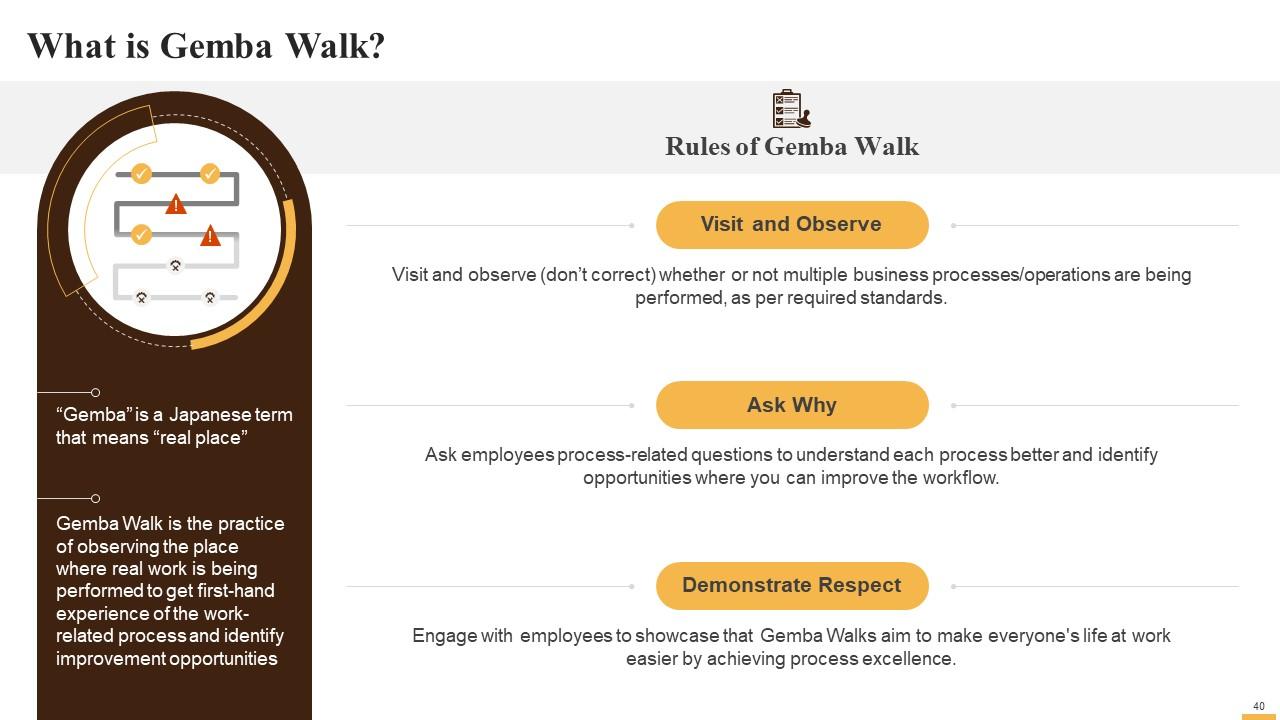

Slide 40

This slide provides an introduction to Gemba Walk, a Kaizen tool. It highlights that the Gemba walk is the practice of observing the place where real work is being performed to get first-hand experience of the work-related processes and identify improvement opportunities. It also lists the rules of the Gemba walk, such as visit and observe, ask why, and demonstrate respect.

Slide 41

This slide list the advantages of the Gemba walk, such as continuous optimization, process standardization, improved communication, chance to demonstrate leadership skills, and strengthening of reputation.

Instructor’s Notes:

Businesses can derive following benefits from the Gemba Walk tool of Kaizen:

- Continuous Optimization: The Gemba Walk helps organizations analyze and improve business processes to foster a culture of continuous improvement

- Process Standardization: It also helps standardize processes that result in resource-saving (financial and human), streamlining business operations

- Improved Communication: Businesses use this technique to improve communication at all organizational levels and helps bring teams closer to find solutions to their problems

- Demonstrate Leadership Skills: It helps cement the manager's leadership qualities by showcasing their manager's effort to visit and observe staff on the production floor

- Strengthen Reputation: It helps to strengthen the company's reputation; the underlying message that goes out is that the company cares about employees' well-being and safety, thus boosting employee morale

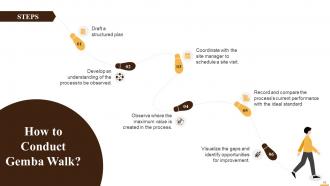

Slide 42

This slide showcases a multistep process to conduct the Gemba Walk, a Kaizen tool for continuous improvement.

Slide 43

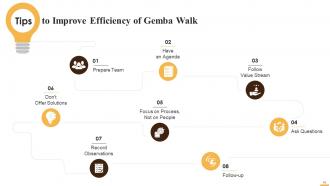

This slide provides information on tips to increase the efficiency of Gemba walk, such as preparing a team, having an agenda, following the value stream, asking questions, focusing on process, not on people, not offering solutions, recording observations, and follow-up.

Instructor’s Notes:

Tips to improve the efficiency of Gemba Walk are as follows:

- Prepare Team: Always brief the team about the Gemba walk's objectives in advance, so they know what to observe. This will ensure employees feel more involved, comfortable, and willing to share observations. If possible, make the interdepartmental teams to ensure varied perspectives can interact

- Have an Agenda: Always draft an agenda for the Gemba walk, such as productivity improvement, cost efficiency, safety enhancement, etc. Then prepare a list of questions in context with the prepared agenda to be asked during the Gemba walk

- Follow Value Stream: During the Gemba walk, always follow the flow of value in the business process; observe areas with a high scope for optimization of non-value-added activities

- Ask Questions: Ask questions (who, what, where, when, and why) to understand business operations better and identify improvement opportunities

- Focus on Process, Not on People: Keep the focus on observing, understanding, and improving the business process. Do not judge and compare team members on efficiency or any other parameter. Note that Gemba walk is not an employee performance evaluation tool

- Don't Offer Solutions: Gemba walk is for observation of business processes only. Avoid offering on-the-spot suggestions

- Record Observations: During the Gemba walk, record everything that grabs attention and analyze collected data later, with complete facts

- Follow-up: Share findings of the Gemba walk with the department under observation. Otherwise, they will feel that they are being scrutinized. If any improvement action is to be taken after the walk, inform the team about the mandated changes and why they are necessary

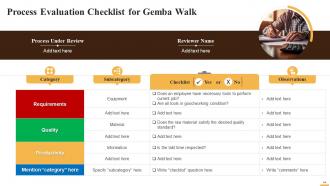

Slide 44

This slide presents a process evaluation checklist that the reviewer can use during the Gemba Walk. The major constituents of the checklist are process under review, category, subcategory, questions, and observations.

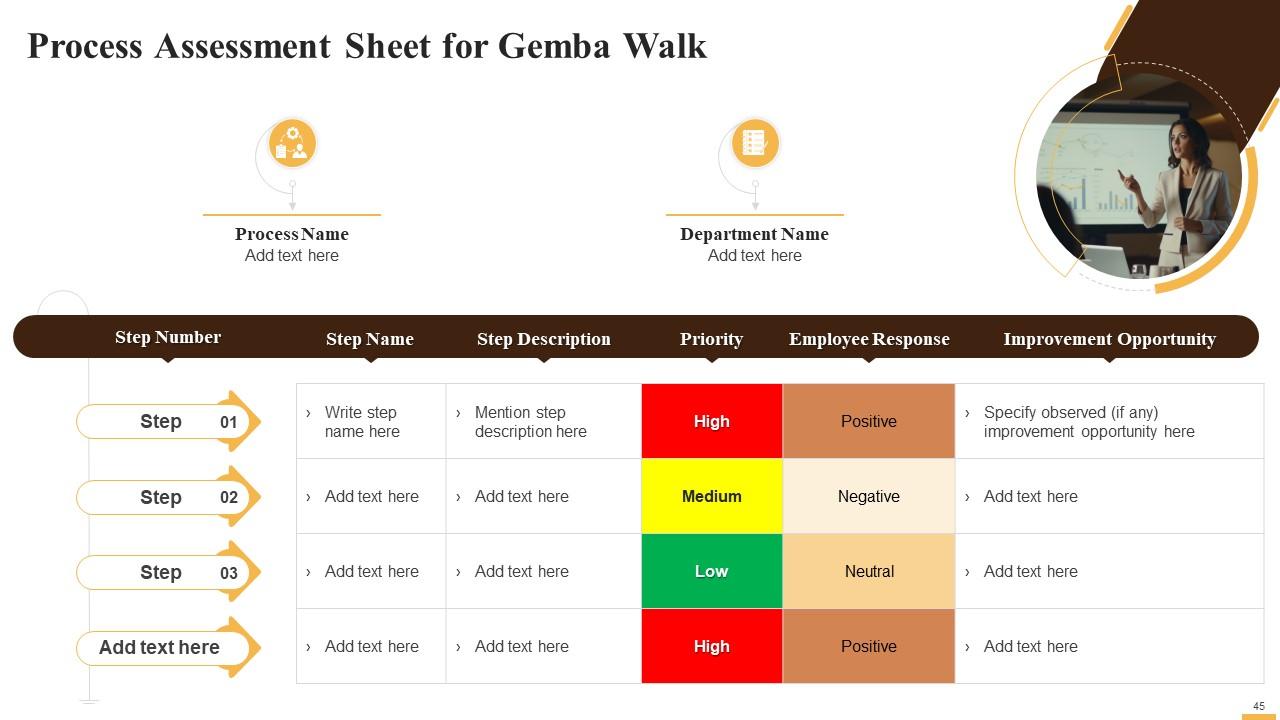

Slide 45

This slide showcases a process assessment sheet for the Gemba Walk. The major constituents of the sheet are step number, description, and improvement opportunities.

Slide 46

This slide lists the purposes of 'The Gemba Walk' activity for the Kaizen training session.

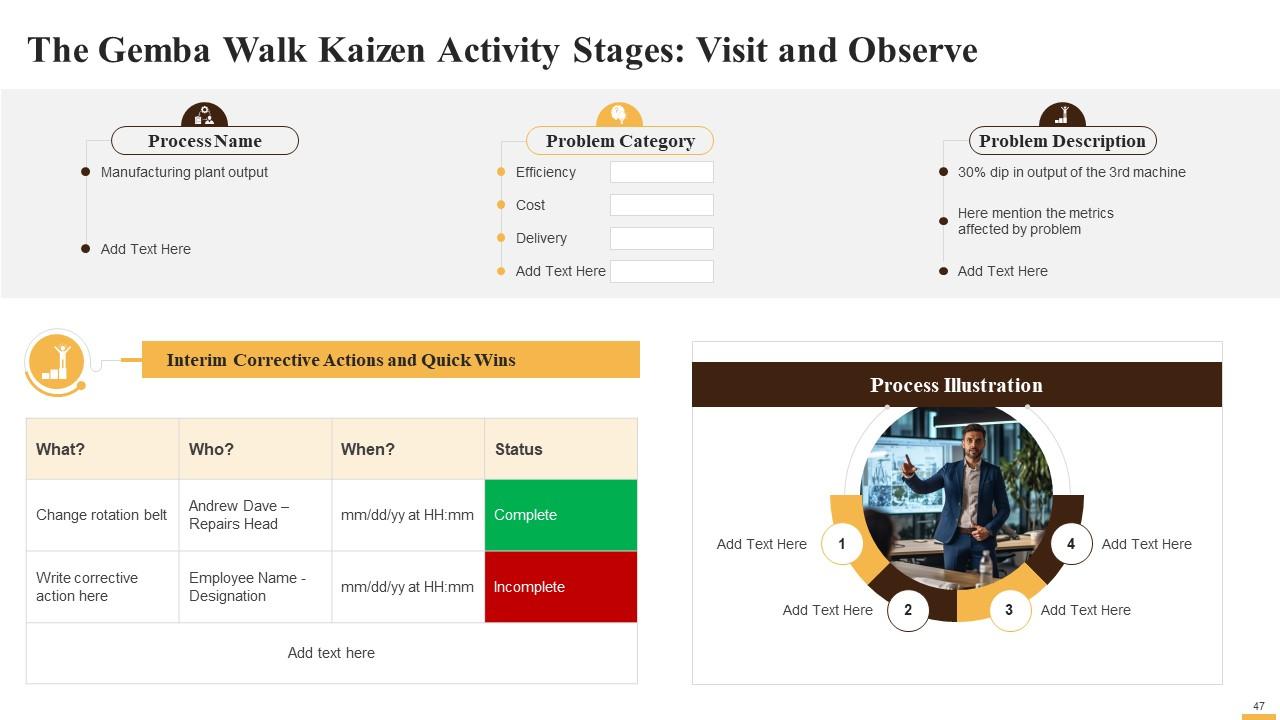

Slide 47

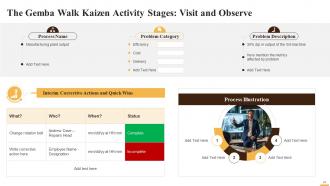

This slide provides the framework to collect data during the visit and observe steps of 'The Gemba Walk,' an activity for the Kaizen training session. The multiple headers are process name and illustration, problem category and description, and interim corrective actions for quick wins.

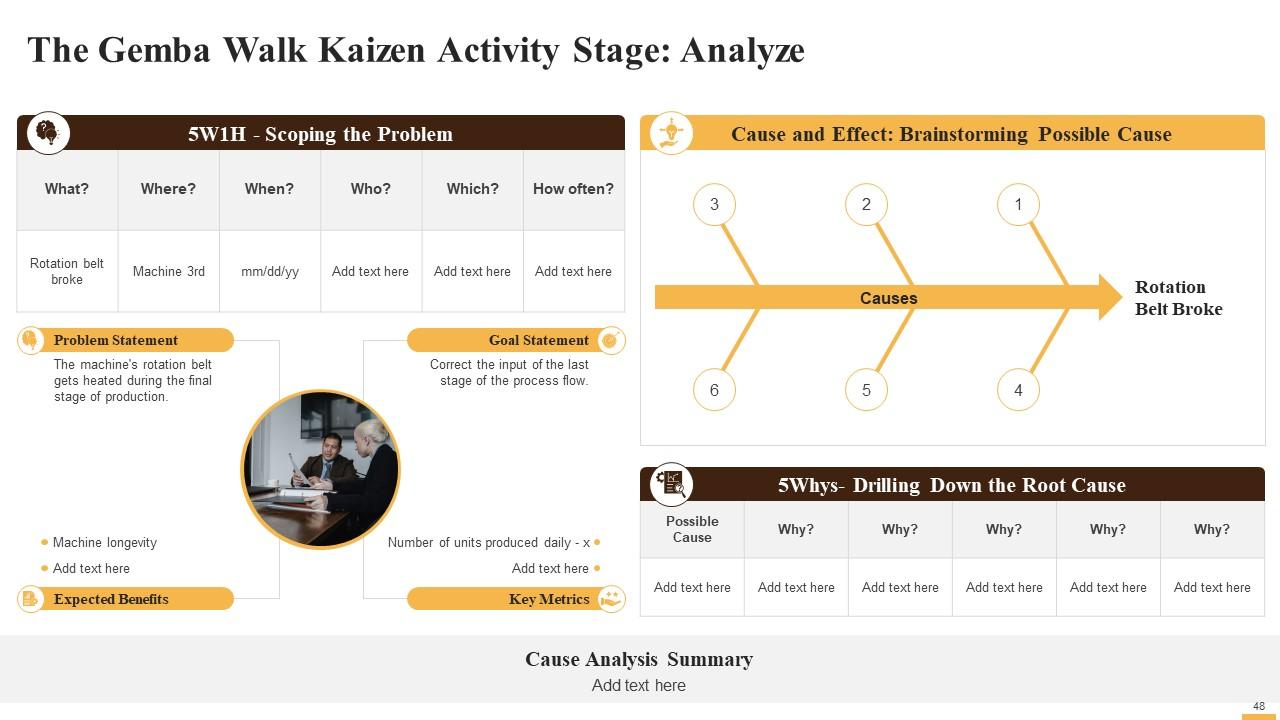

Slide 48

This slide provides the framework to evaluate the problem data during the analyze step of 'The Gemba Walk,' an activity for the Kaizen training session. The multiple continuous process improvement techniques used are 5W1H (Who, What, Why, When, Where, and How), Cause and Effect Diagram, and the 5 Whys.

Slide 49

This slide provides the framework for the act step of 'The Gemba Walk,' an activity for the Kaizen training session. The key headers are solution description, corrective actions, and result summary.

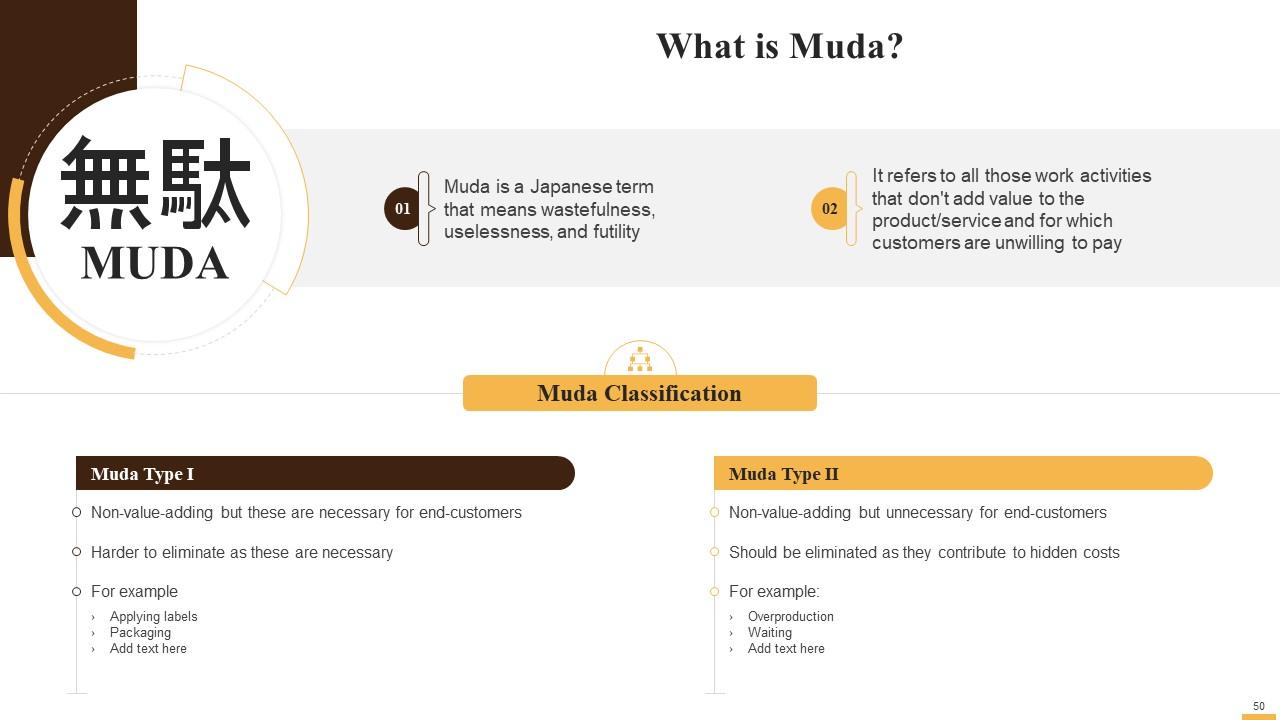

Slide 50

This slide provides an overview of Muda (Waste), all those work activities that don't add value to the product/service and for which customers are unwilling to pay. It includes details of Muda classification, such as Muda type I, which are applying labels, packaging, etc., and Muda type II, which are overproduction, waiting, etc.

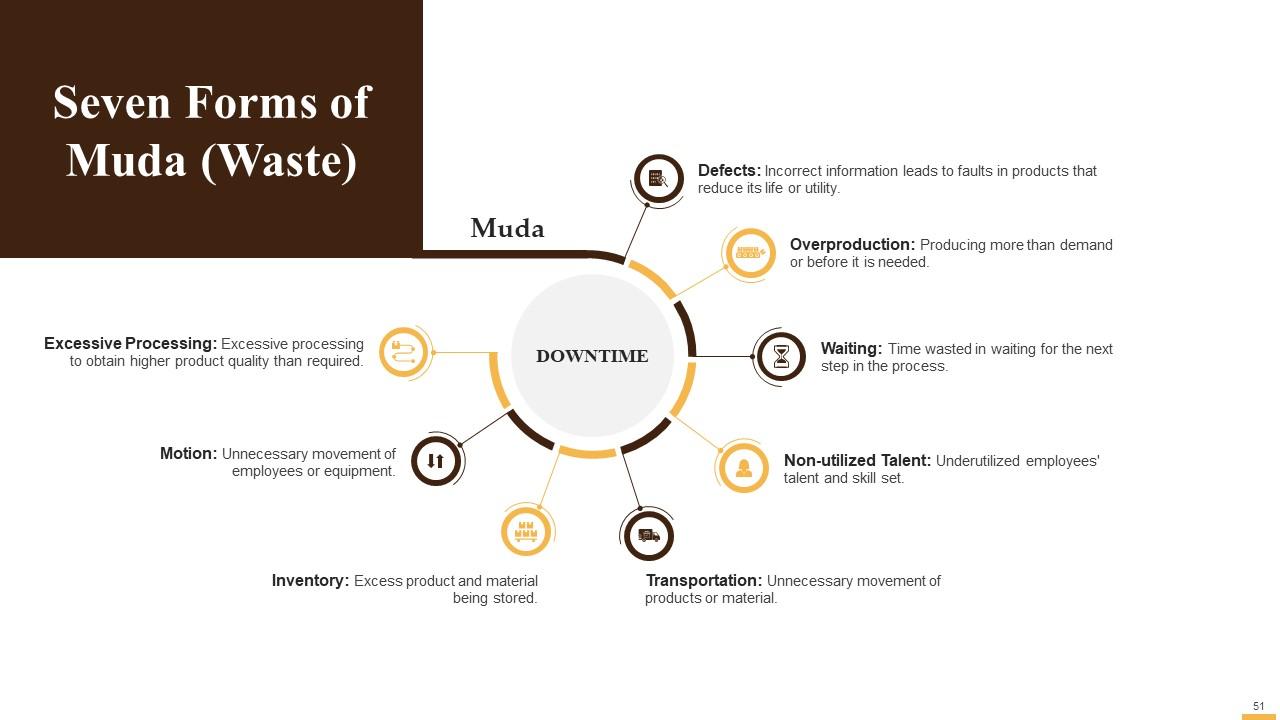

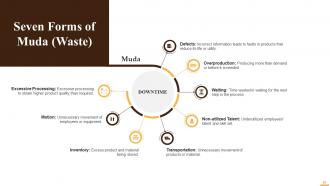

Slide 51

This slide highlights the seven categories of waste in Kaizen. The wastes listed are defects, overproduction, waiting, non-used employee talent, transportation, inventory, motion, and excessive (over) processing. Together they create the mnemonic DOWNTIME and are also known as Toyota's or Ohno's seven forms of waste.

Slide 52

This slide provides information on the core objective of Kaizen mythology, i.e., the identification and elimination of waste. It also lists the benefits of such waste elimination, which are lower operating costs, reduced lead time, enhanced "speed time to market," etc.

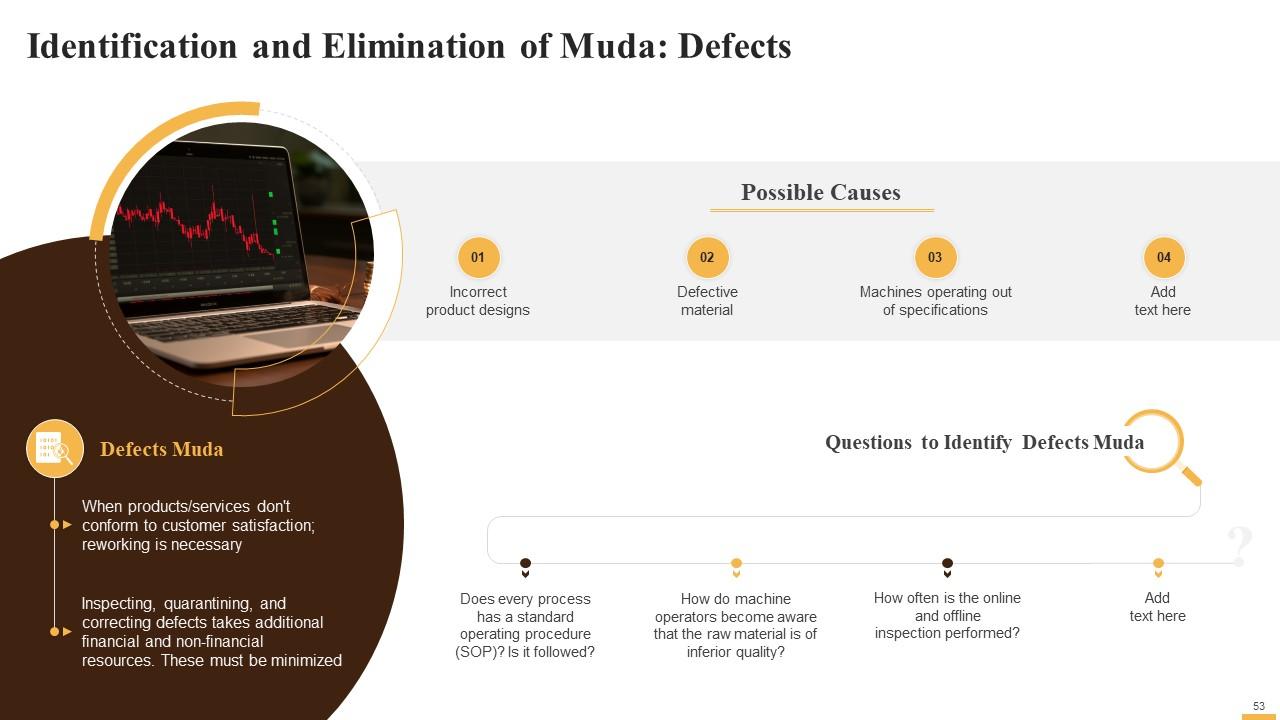

Slide 53

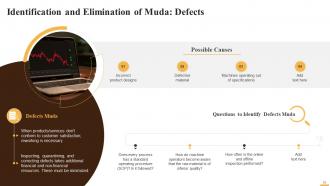

This slide provides information about the definition of defects, a type of Muda, and its causes. It also contains questions to identify defects at the workplace.

Slide 54

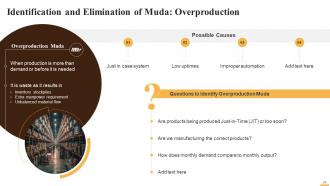

This slide provides an introduction to overproduction Muda. It also contains questions to identify and minimize it at the workplace as per the Kaizen methodology for quick improvement.

Slide 55

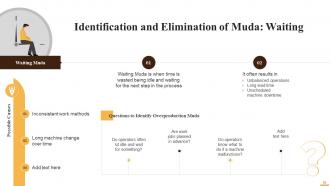

This slide provides information, on a type of Kaizen Muda, Waiting, and its causes. It also contains questions to identify and minimize "Waiting Waste" at the workplace.

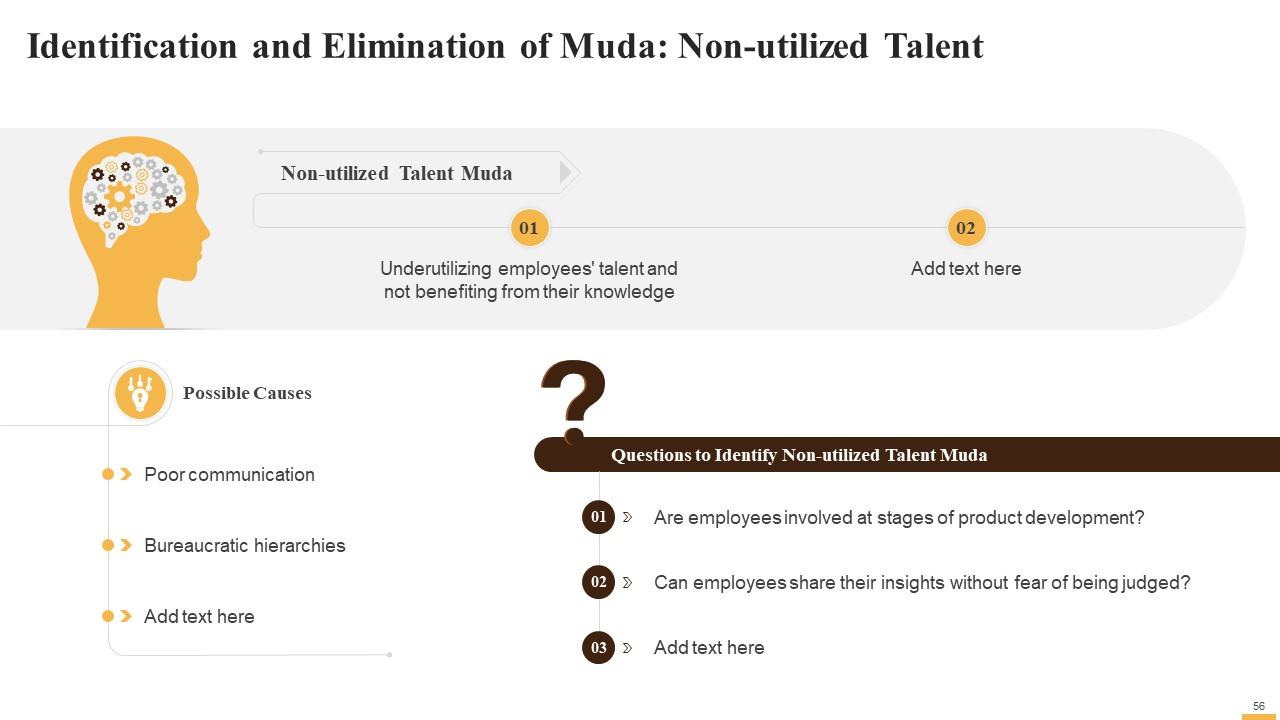

Slide 56

This slide covers the concept of Kaizen waste Non-utilized Talent. It includes possible causes of waste along with the questions that help identify it.

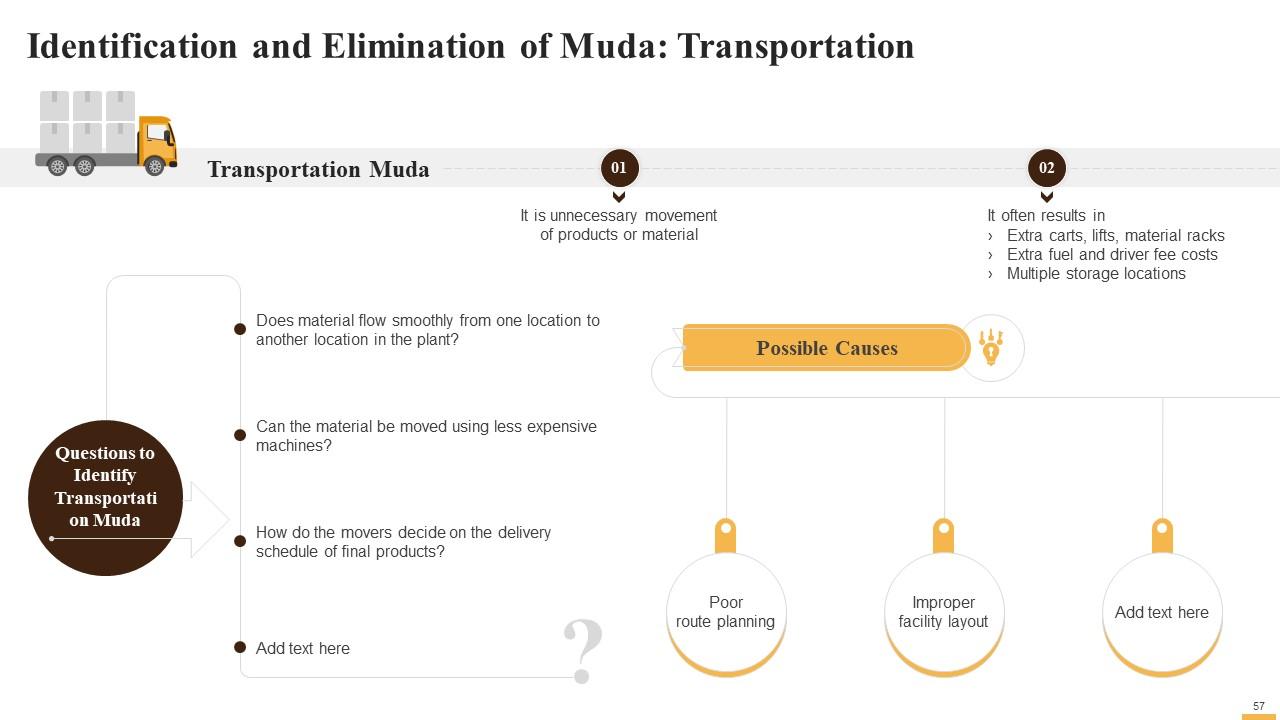

Slide 57

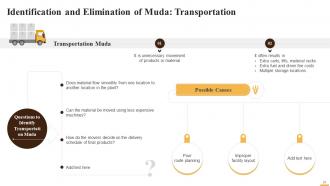

This slide covers the concept of Kaizen waste Transportation. It includes possible causes of transportation Muda along with the questions to identify and minimize it.

Slide 58

This slide highlights the Kaizen Muda excessive inventory and provides details about possible causes and questions to identify and reduce it at a workplace.

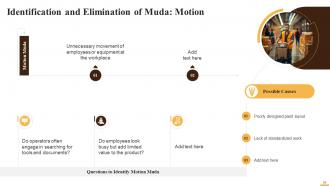

Slide 59

This slide highlights the Kaizen Muda of unnecessary motion. It also lists the questions to identify it at a workplace for reduction.

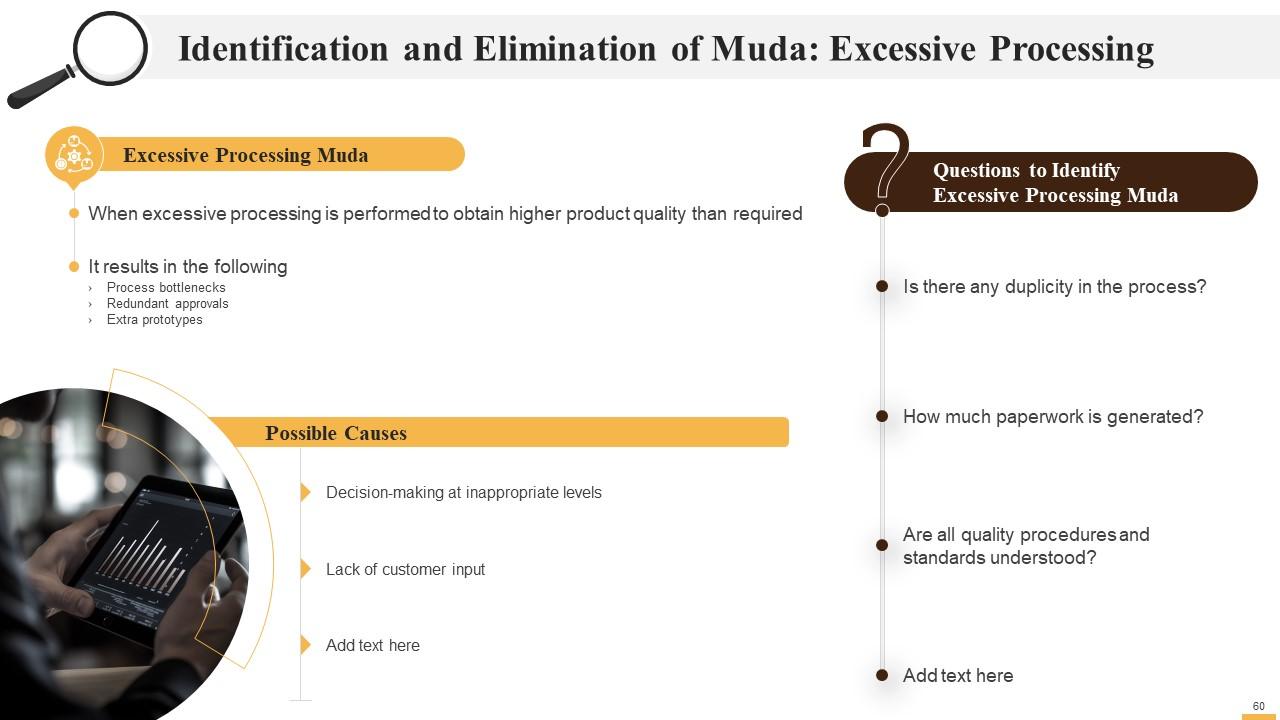

Slide 60

This slide covers the concept of excessive processing Muda and includes the possible causes of waste occurrence and questions to identify and minimize it.

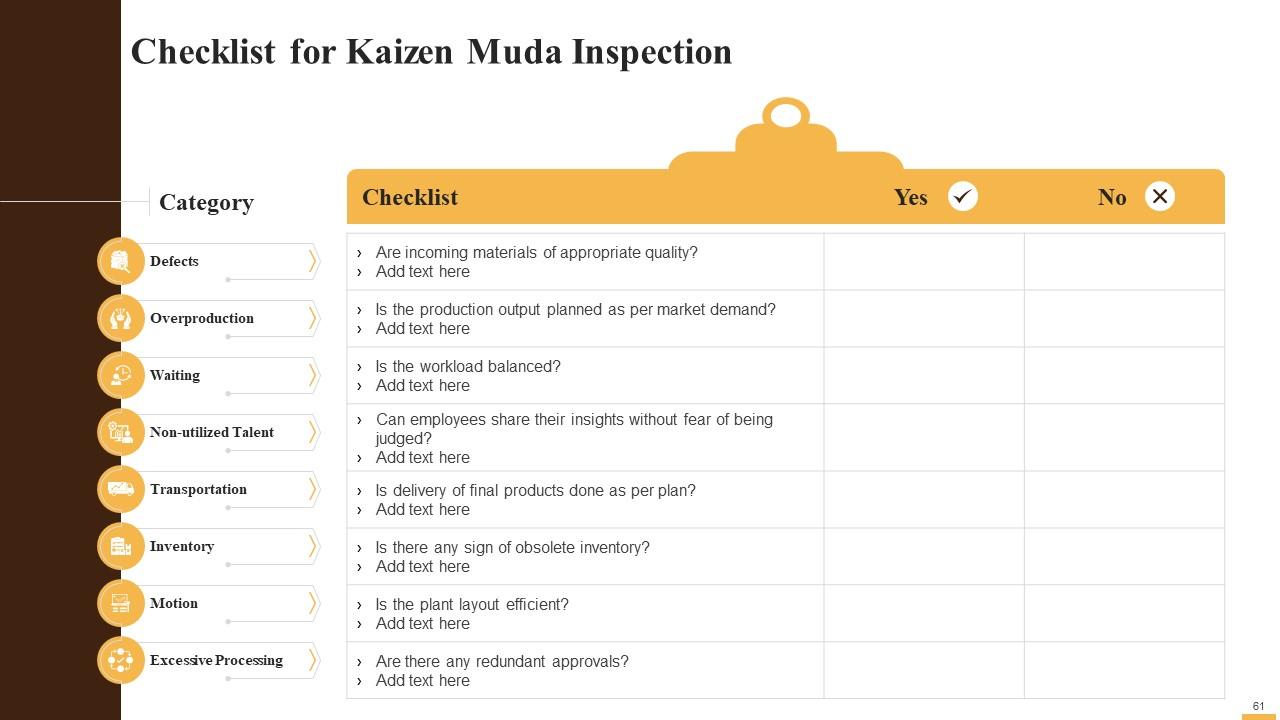

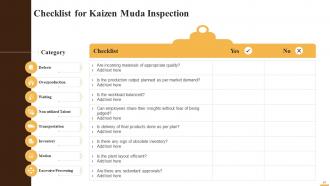

Slide 61

This slide contains checklist for Kaizen Munda that an auditor can use for waste inspection during the Gemba Walk.

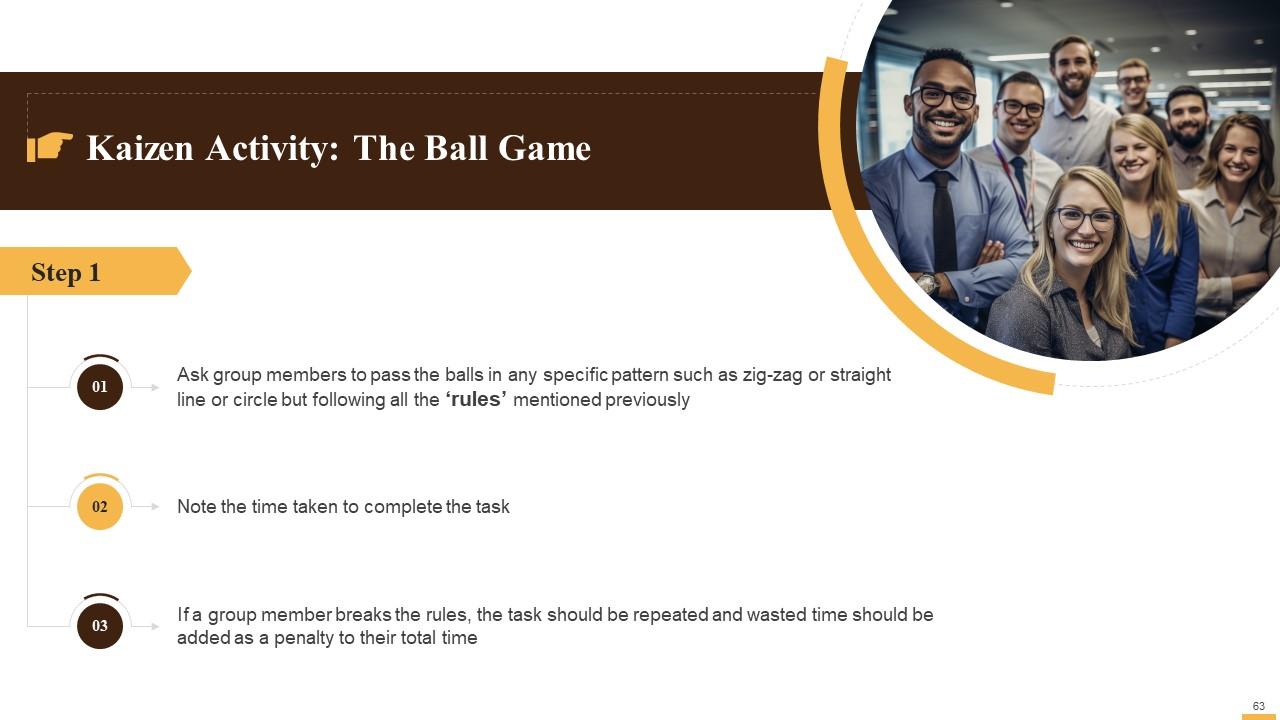

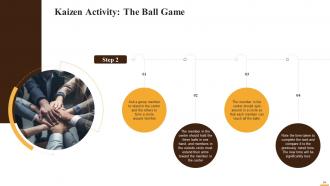

Slide 62 to 65

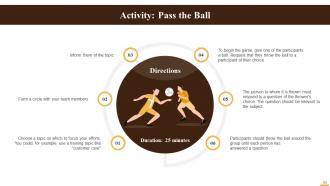

These slides contain the prerequisite and rules of ‘The Ball Game’ exercise for the Kaizen training session.

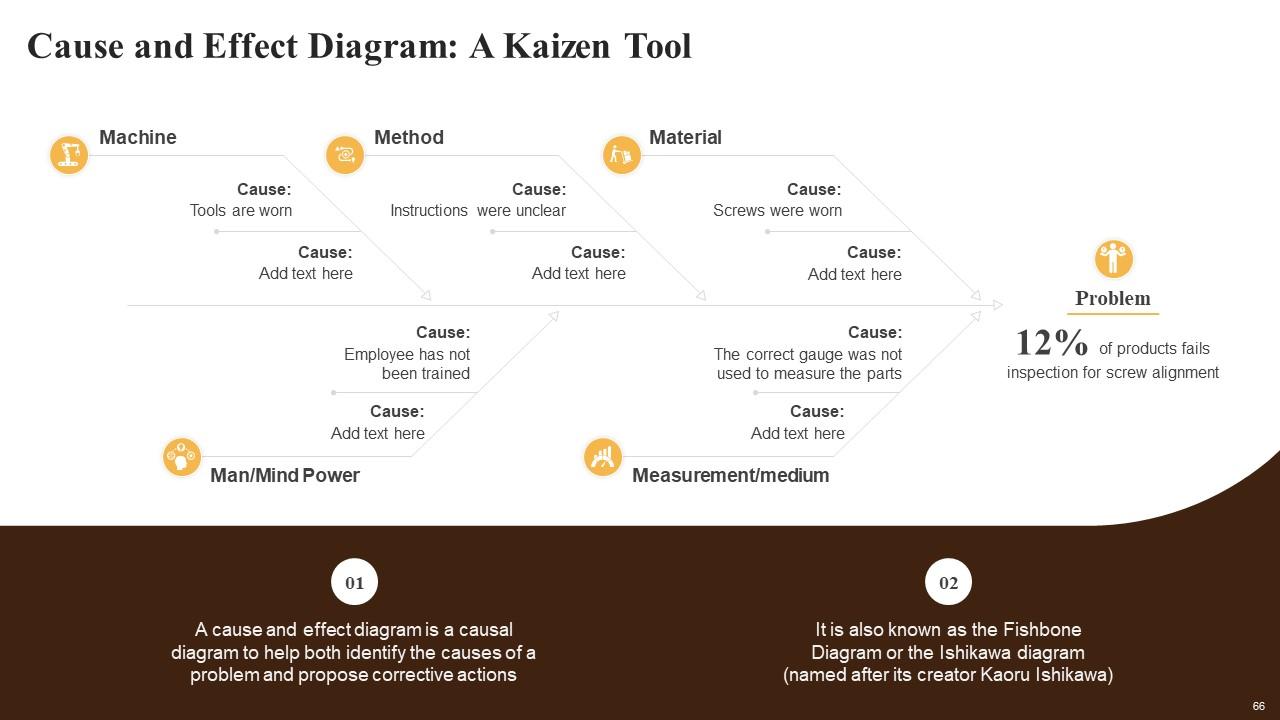

Slide 66

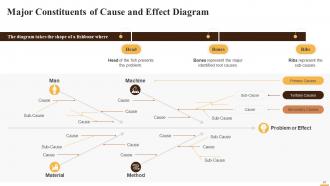

This slide provides information about the cause and effect diagram, i.e., a causal diagram, to help both identify the causes of a problem and propose corrective actions. It is also known as the fishbone diagram or the Ishikawa diagram (named after its creator Kaoru Ishikawa).

Slide 67

This slide visually presents the fishbone diagram or the Ishikawa diagram highlighting its major constituents i.e., problem, primary, secondary, and tertiary causes.

Slide 68

This slide highlights the multiple advantages of the Fishbone Diagram or the Ishikawa diagram, such as promoting critical thinking among team members with its focus on causes, not on symptoms, encouraging the whole team to participate in continuous improvement, etc.

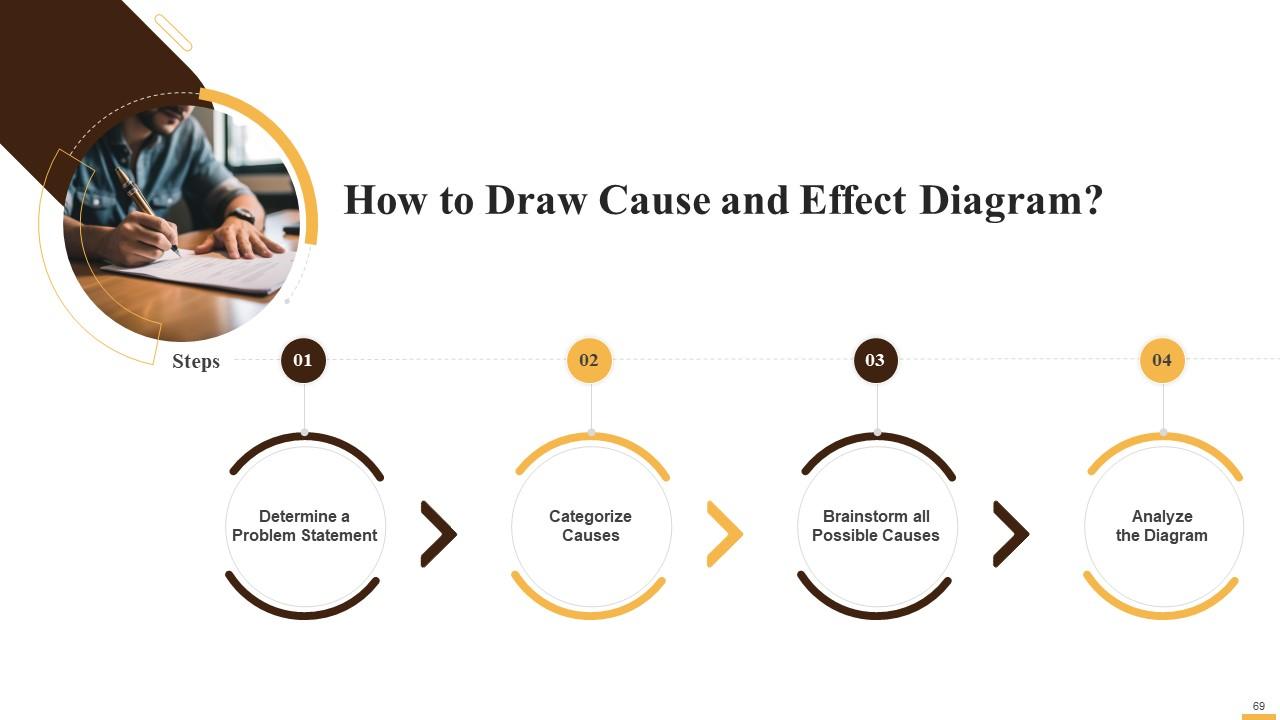

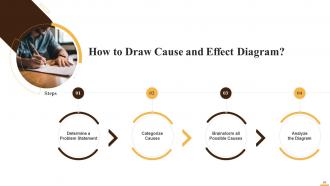

Slide 69

This slide showcases the process of drawing a cause and effect diagram. The major steps are determine a problem statement, categorize causes, brainstorm all possible causes, and analyze the diagram.

Instructor’s Notes:

The major steps to draw a cause and effect diagram are:

- Determine a Problem Statement: Clearly define the business problem and write it at the head of the fish. Then draw a horizontal arrow pointing to the fish head across the page as the fish's backbone

- Categorize Causes: Categorize the problem's causes into groups. The popular frameworks for categorization used are as follows:

- 6Ms: Machine, Methods, Mother Nature, Material, Measurement, Manpower

- 6Ps: People, Process, Policy, Plant, Programs, Products

- 4S: Surroundings, Suppliers, Systems, Skills

Draw categories as the fish's bones with arrows pointing to the backbone

- Brainstorm all Possible Causes: Identify contributing causes to each cause category. Represent these as branches of the fish's bones. Further, identify sub-causes and use these to represent ribs that to show the causal relationships

- Analyze the Diagram: Analyze all major and contributing causes by asking ‘why’ questions and identify the root cause of the problem. If the root cause of the stated problem is still not identified, then shift focus to the diagram area with fewer ideas and continue brainstorming

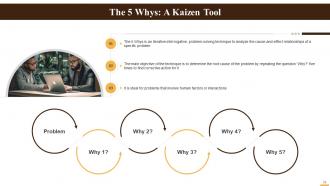

Slide 70

This slide provides information about the 5 Whys, i.e., an iterative interrogative, problem-solving technique to analyze the cause-and-effect relationships of a specific problem.

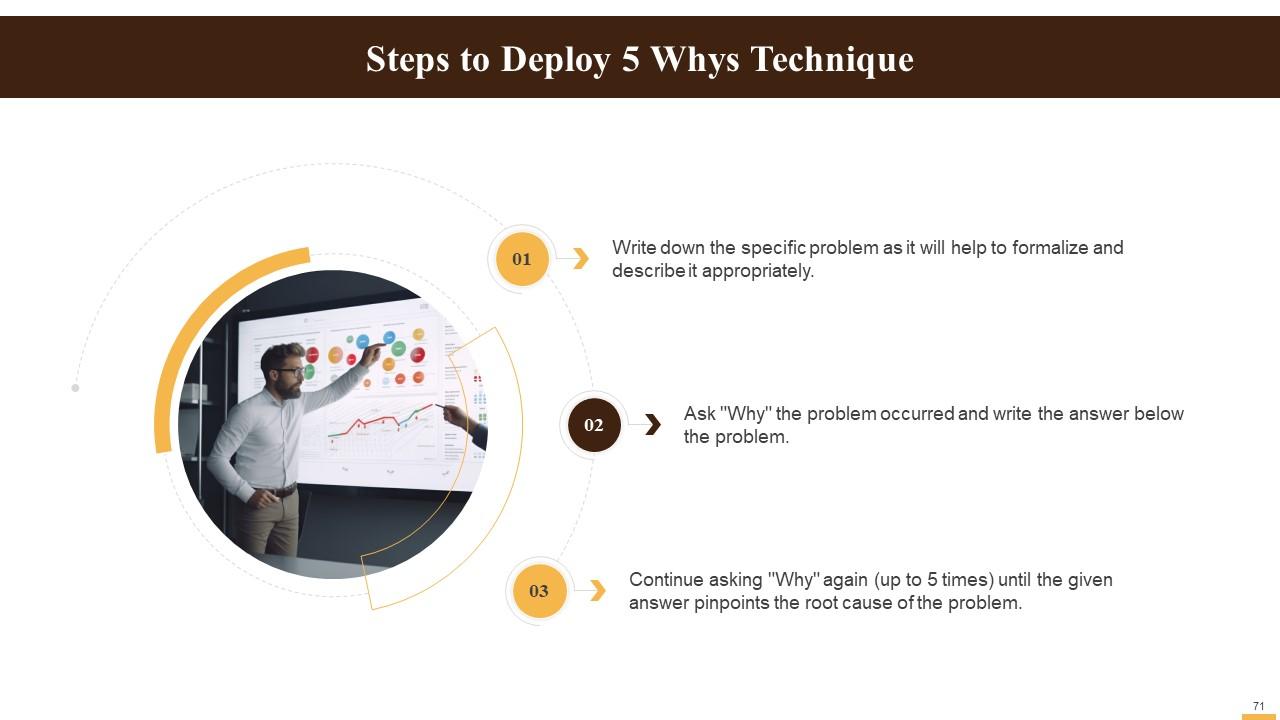

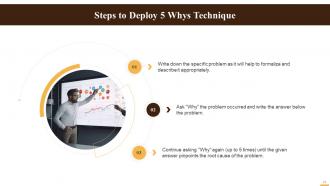

Slide 71

This slide highlights the process to deploy 5 Whys techniques to identify the root cause of the problem in Kaizen.

Slide 72

This slide highlights an example to showcase five whys technique for finding out the root cause of the problem.

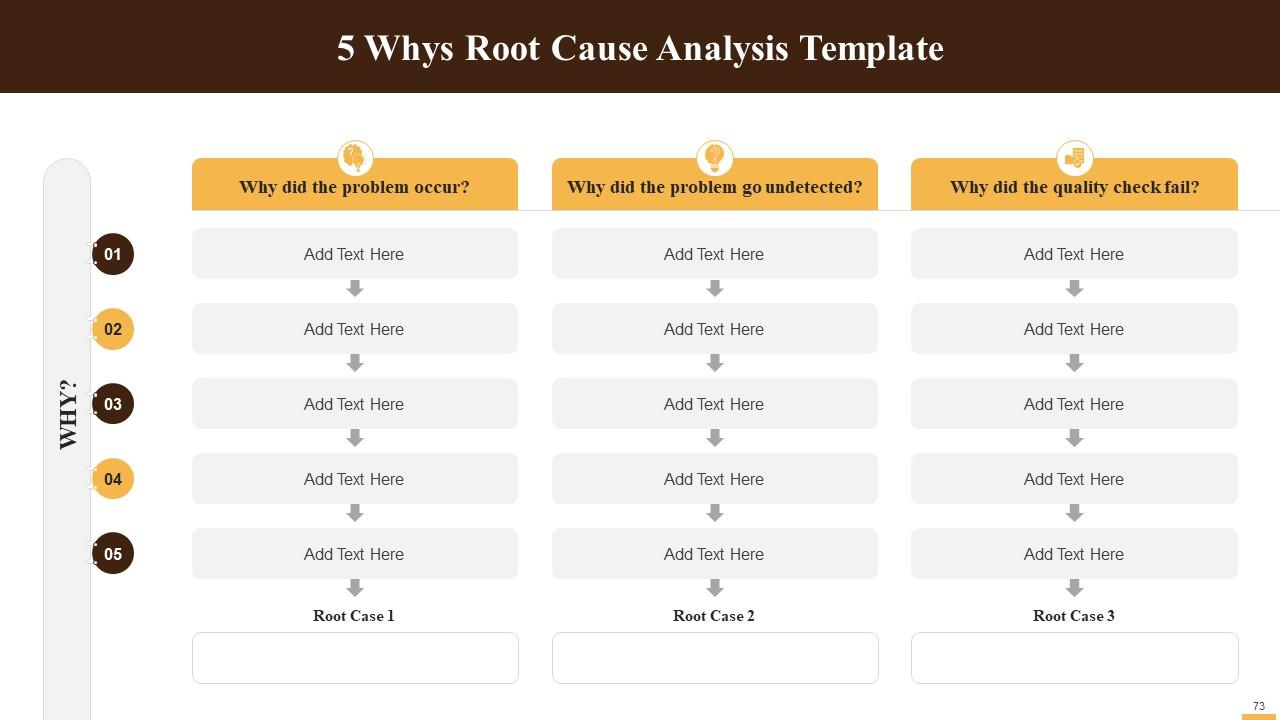

Slide 73

This slide presents a template for 5 Whys technique to conduct root cause analysis of the business problem.

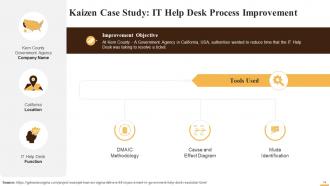

Slide 74

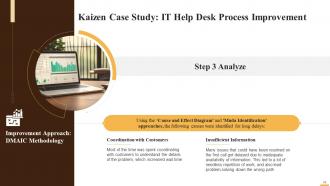

This slide contains the improvement objectives and tools used (DMAIC Methodology, Cause and Effect Diagram, and Muda Identification) in a case study for the Kaizen training session.

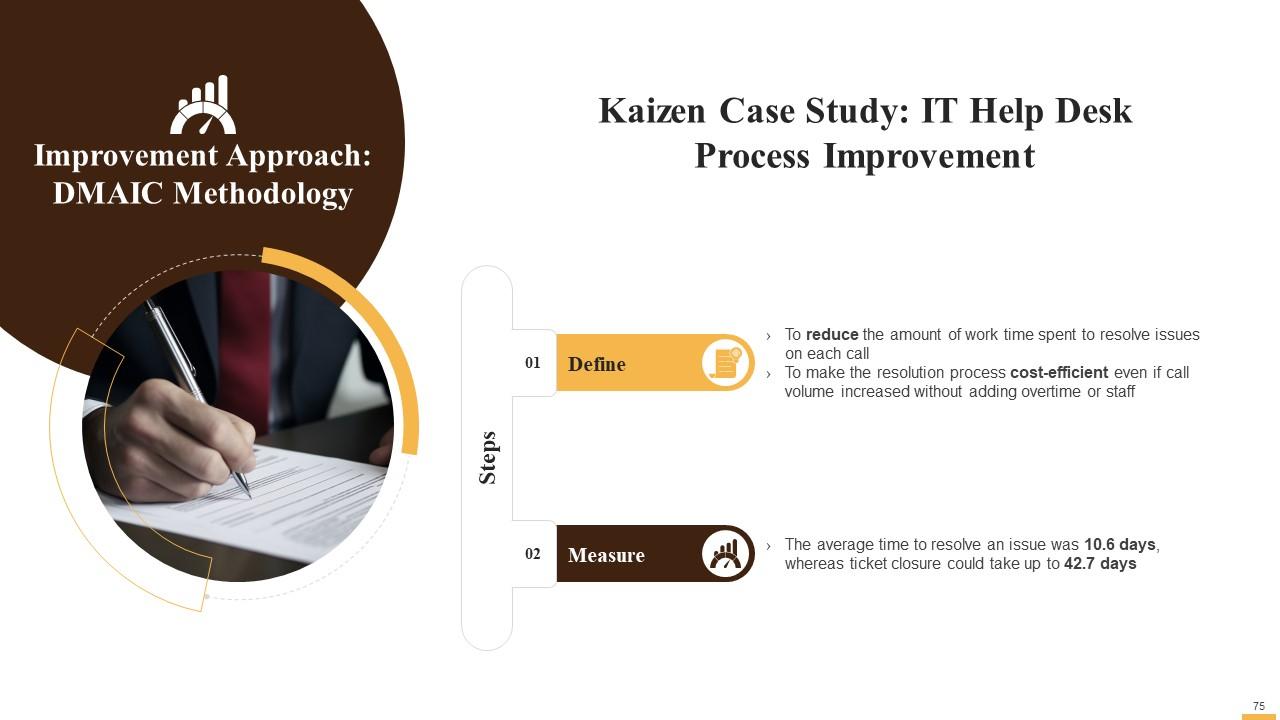

Slide 75

This slide contains the outcomes of the define and measure steps of the DMAIC Methodology used in the IT Help Desk Process Improvement case study for the Kaizen training session.

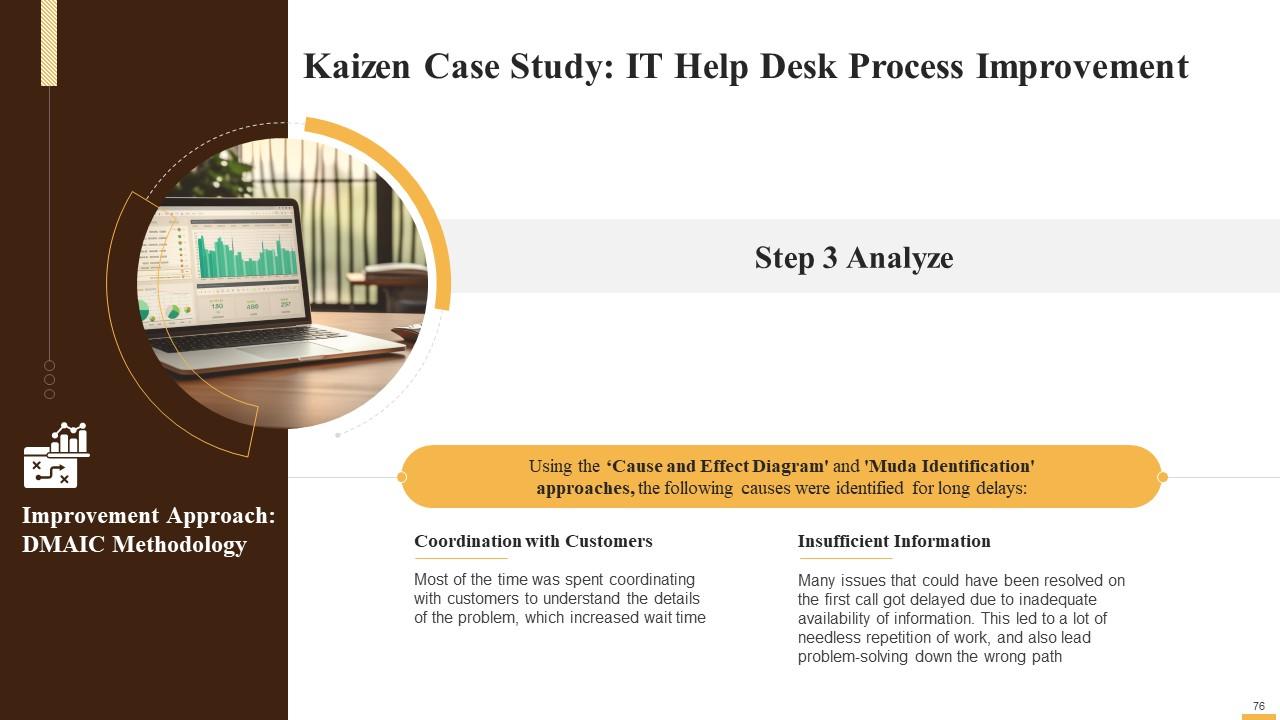

Slide 76

This slide contains the outcomes of the analyze step of the DMAIC Methodology used in the IT Help Desk Process Improvement case study for the Kaizen training session.

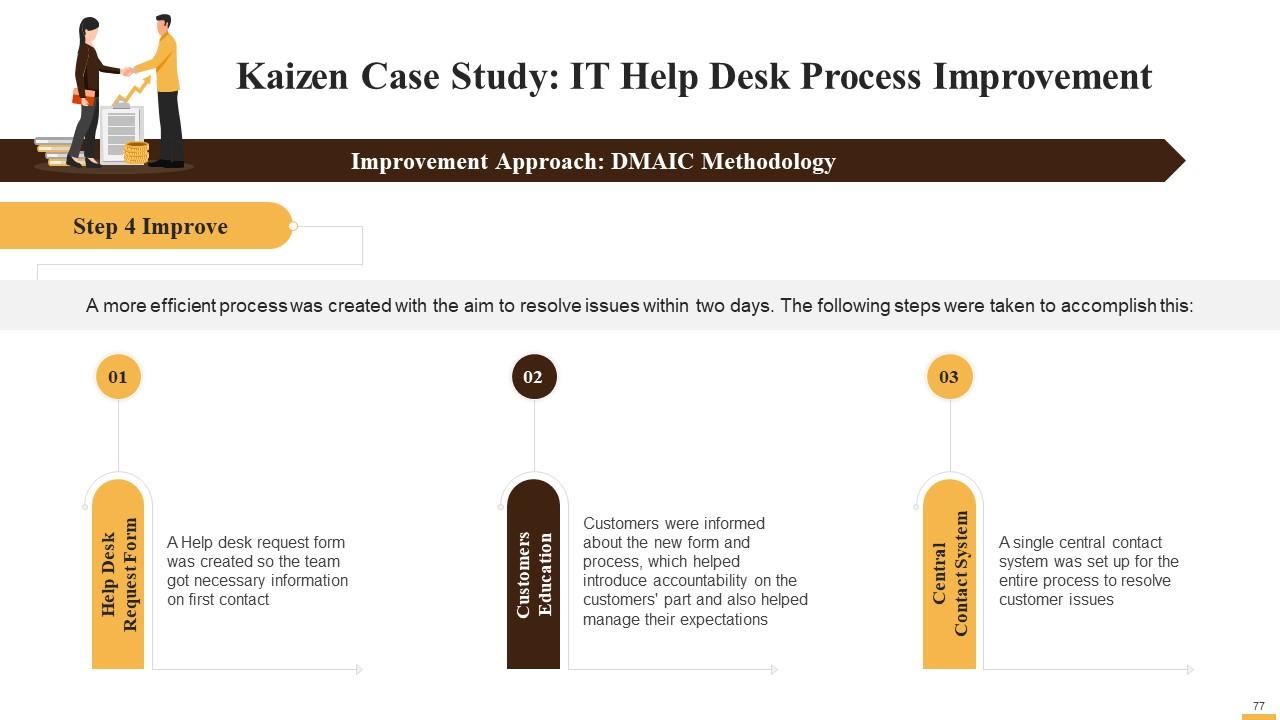

Slide 77

This slide contains the outcomes of the improve step of the DMAIC Methodology used in the IT Help Desk Process Improvement case study for the Kaizen training session.

Slide 78

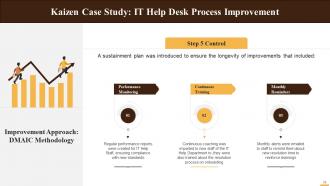

This slide contains the outcomes of the control step of the DMAIC Methodology used in the IT Help Desk Process Improvement case study for the Kaizen training session.

Slide 79

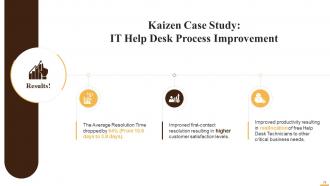

This slide showcases of IT Help Desk Process Improvement case study for the Kaizen training session.

Slide 80

This slide provides information about the visual factory, a methodology in which multiple visual cues at the workplace or manufacturing plant are displayed. These cues are used to communicate information to employees or workers to improve efficiency, safety, and productivity. It also provides information about what should be displayed (process metrics, work instructions, and general plant information) and where to display it (walls, floors, machines, ceilings, and vehicles).

Instructor’s Notes:

Visual tools are used to share the following information:

- Process Metrics: Process metrics such as operating capacity, the voltage used, etc., are displayed on machines to provide information in real-time to ensure that required adjustments can be immediately made to a process

- Work Instructions: Work tasks instructions about what to do and when to do to minimize production errors. It also includes any instructions related to process safety, such as wearing protective gear

- General Plant Information: It includes visual information warnings related to any change, such as construction/digging sites, machine movements, and handling potentially dangerous material

Slide 81

This slide provides information on types of visual tools such as signs, posters, labels, floor markings, and charts. It also covers details of why to use these.

Instructor’s Notes:

Visual tools that are often used in the workplace are:

- Signs: Pre-printed or custom signs to display specific information. For example, a STOP sign displayed outside a prohibited area

- Posters: Posters are bigger in size and contain significant information. These are displayed to convey general instructions for safety or job procedures

- Labels: Labels are often placed for quick identification of machines and equipment

- Floor Markings: Floor markings are used to outline boundaries and provide direction to employees

- Charts: Charts are used to visually showcase quantitative information

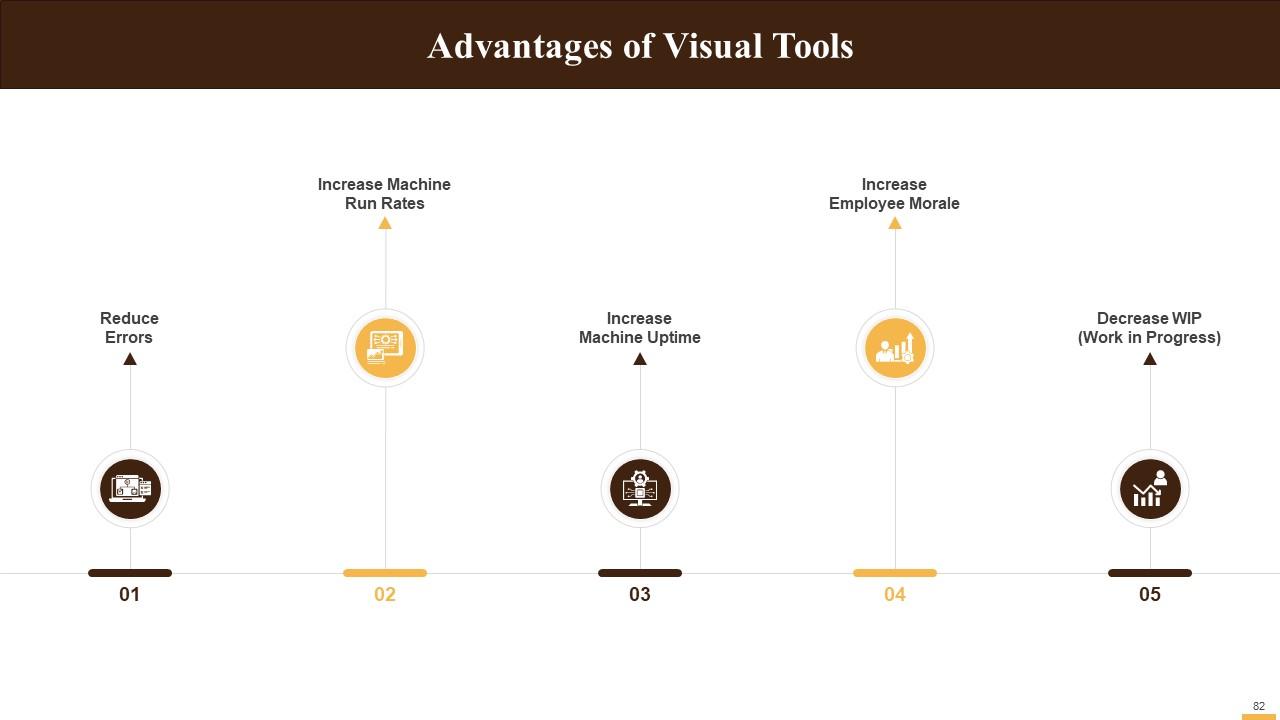

Slide 82

This slide lists advantages of visual tools, such as reduced errors, increased employee morale, machine uptime, machine run rates, and decreased work-in-progress tasks.

Instructor’s Notes:

Visual factory allows organizations to disseminate information and deliver world-class performance. Its benefits are:

- Reduce Errors: Using signs, labels, and posters ensure no steps are forgotten and tasks are performed accurately. These also help reduce human errors and create a more efficient and safer workplace

- Increase Machine Uptime: Visual tools encourage reinforced learning, leading to perfect memorization of steps. Hence changeovers and maintenance tasks can be completed more quickly, leading to significantly higher machine uptime

- Decrease WIP (Work in Progress): Visual production cues such as charts help identify and remove bottlenecks to decrease work in progress (WIP) tasks

- Increase Machine Run Rates: Visual cues such as a color-coded calendar for scheduling machine maintenance and instructions about machine inputs result in higher machine uptime, leading to fewer machine breakdowns

- Increase Employee Morale: Well-displayed visual instructions (for complex tasks) give employees the confidence to do their jobs successfully. Also, using charts to display real-time data on a manufacturing plant’s shift motivates operators to achieve set targets, giving them instant feedback on their progress

Slide 83

This slide contains the problem statement and improvement approach used (Gemba Walk and 8 Wastes Checklist) in the case study for the Kaizen training session.

Slide 84

This slide showcases the Gemba Walk findings for the case study on cost saving in claims warranty for the Kaizen training session.

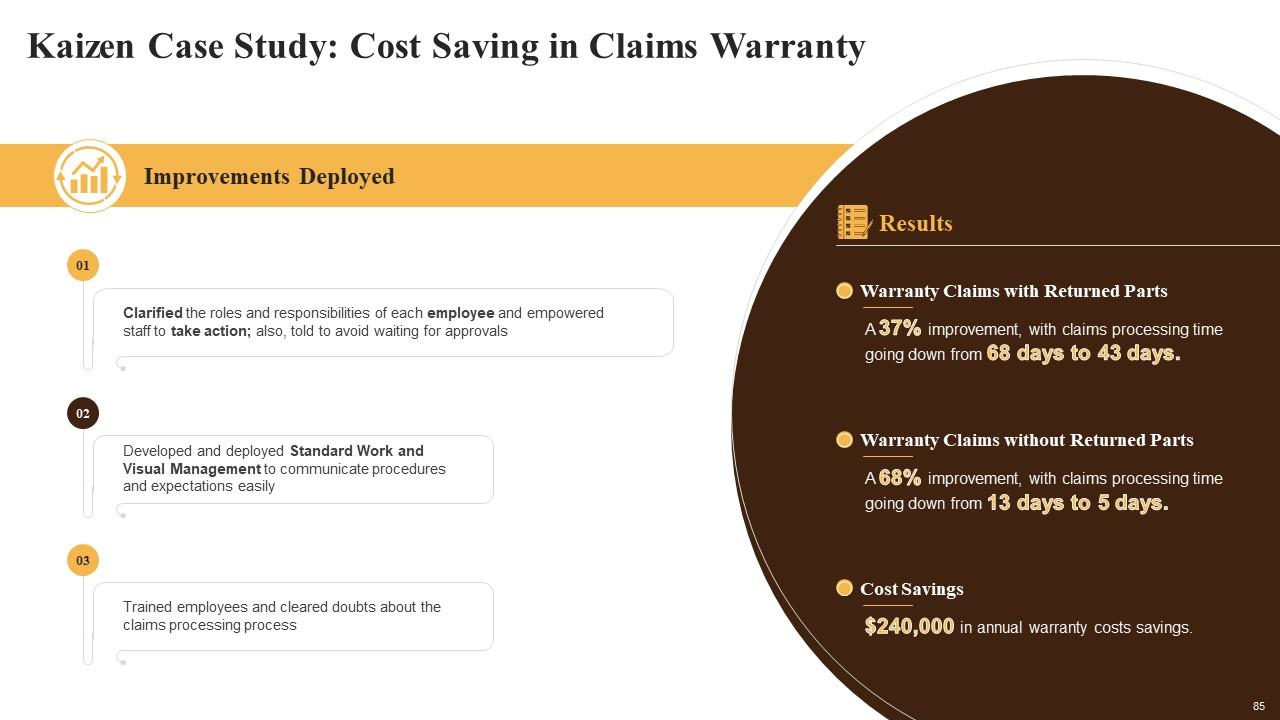

Slide 85

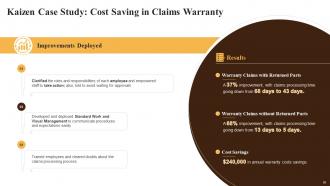

This slide highlights improvements deployed and results achieved for the case study on cost saving in claims warranty for the Kaizen training session.

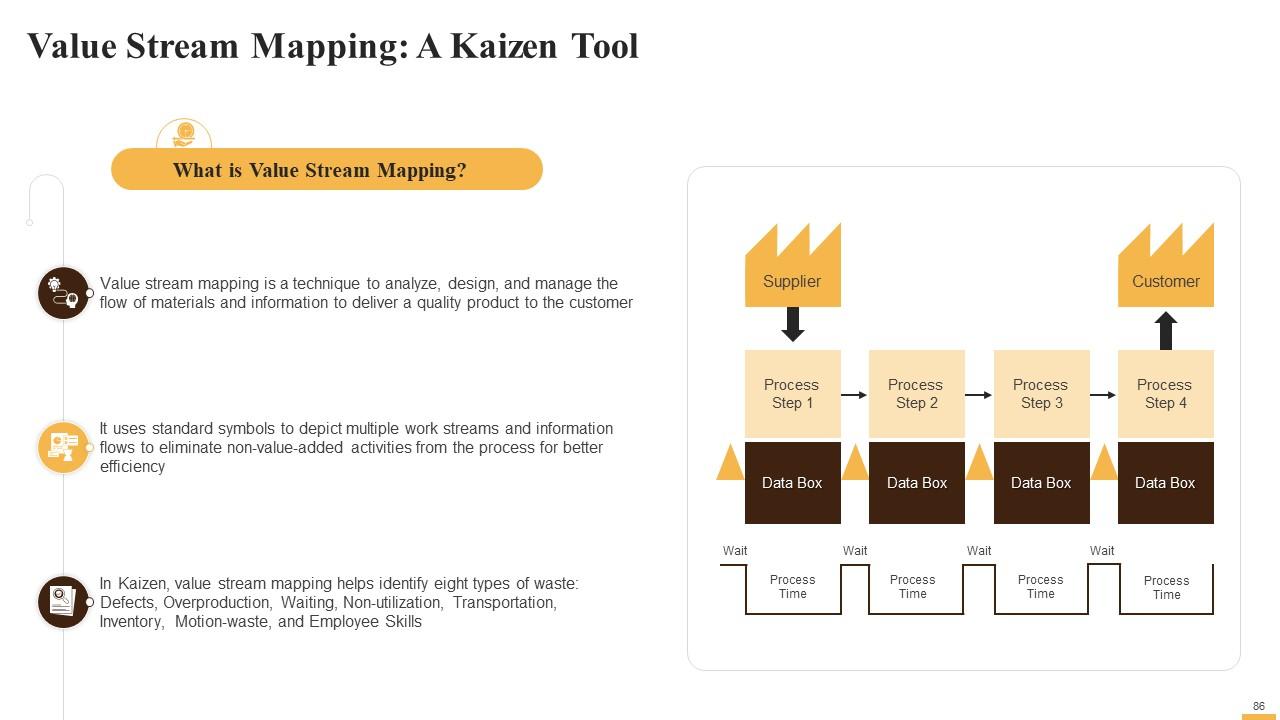

Slide 86

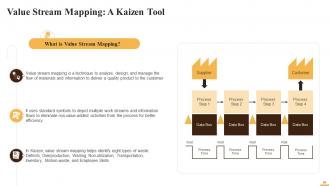

This slide provides information about the concept of value stream mapping, a technique to analyze, design, and manage the flow of materials and information to deliver a quality product to the customer. In Kaizen, value stream mapping helps identify eight types of waste: Defects, waiting, non-utilization, transportation, inventory, motion waste, and employee skills.

Slide 87

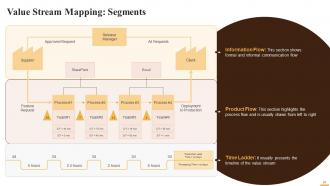

This slide reflects the major sections of a value stream map, such as information flow, product flow, and time ladder.

Instructor’s Notes:

The three major sections of a value stream map are:

- Information Flow: This section shows formal and informal communication flow. Note that there is no standardized direction of communication flow, as it can flow in any direction

- Product Flow: This section highlights the process flow that is usually drawn from left to right. Any subtasks or parallel tasks are also drawn beneath the main flow. It also includes details related to the team performing the task and data points of crucial process KPIs (Key Performance Indicators). The yellow boxes showcase number of tasks pending in a particular process

- Time Ladder: This section visually presents the timeline of the value stream. The upper portion of the time ladder showcases the average wait time a process task spends in the queue. The lower portion of the time ladder highlights the average time, when value is actually being added to the feature/product during that stage of process

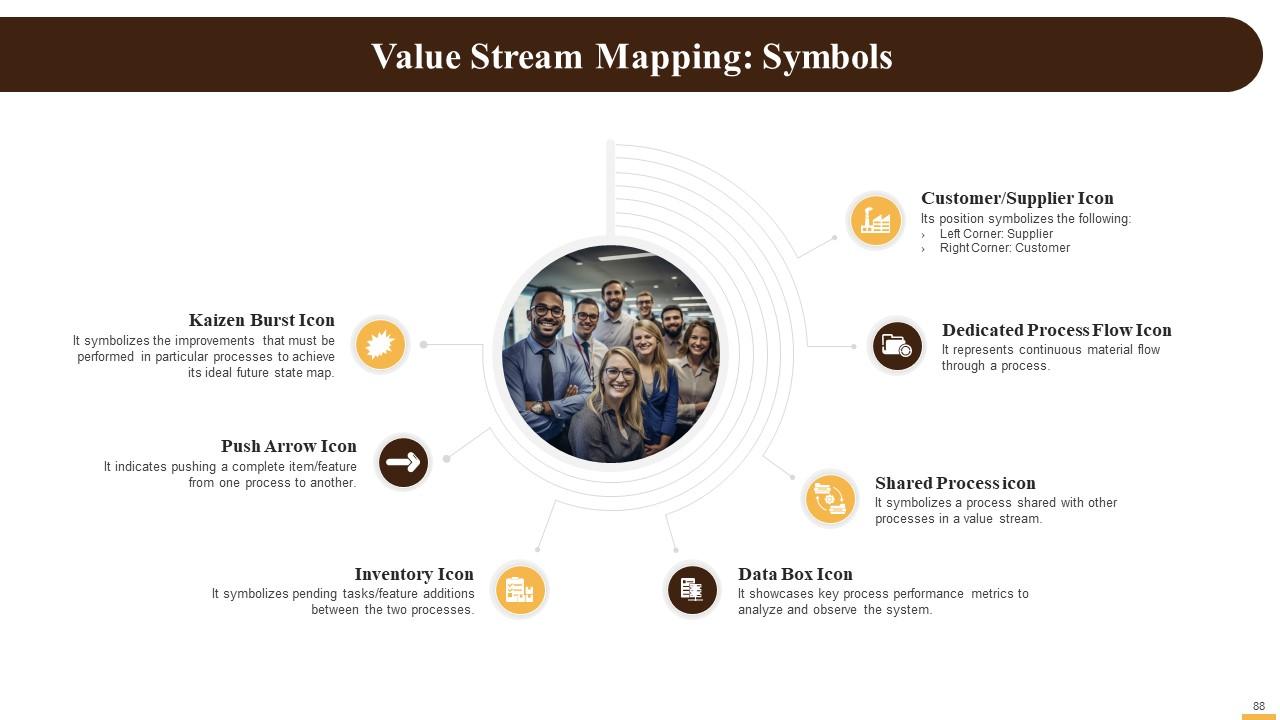

Slide 88

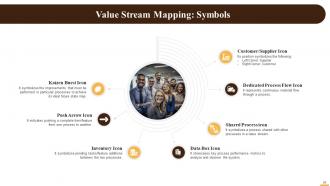

This slide showcases common symbols used in value stream mapping: Customer/Supplier, Dedicated Process Flow, Shared Process, Data Box Icon, Inventory, Push Arrow, and Kaizen Burst Icon.

Slide 89

This slide provides information about value stream mapping performance metrics such as Cycle Time, Setup Time (S/T), Uptime (%), Lead Time, Takt Time, and Kaizen Blitz.

Instructor’s Notes:

How to Calculate Takt Time?

- 7.5 hours per working day (x) 20 work days per month = 150 work hours per month available

- 150 work hours per month = 9,000 working minutes per month

- If a client submits an average of 150 features requests per month

- So, Takt Time = Available Working Minutes per Month/Average Count of Features Requested

- Takt Time = 9,000/150 = 60 minutes

- Hence, one feature should be produced in 60 minutes or less to meet client demand

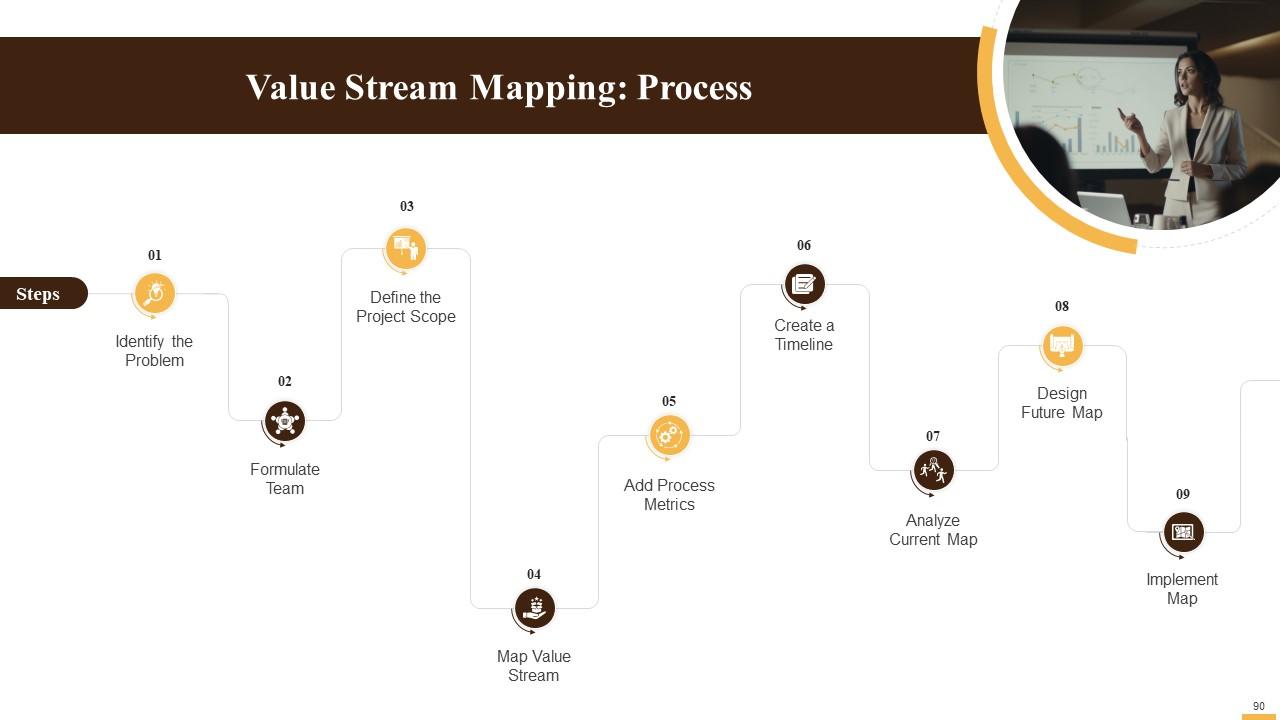

Slide 90

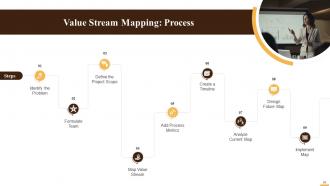

This slide showcases the process of drawing a value stream map. The steps are: Identify the problem, formulate the team, define project scope, map value stream, add process metrics, create a timeline, analyze the current map, design a future map, and implement the map.

Instructor’s Notes:

The steps of the value stream mapping (VSM) process are:

- Step 1 - Identify the Problem: Think from the customer's viewpoint and conduct brainstorming sessions to identify both internal and external process inefficiencies

- Step 2 - Formulate Team: Choose employees from departments to make a cross-functional Value Stream Mapping (VSM) team that will have varied perspectives. Keep a mix of both executives and those in supporting roles in the VSM team for better visibility of internal issues. Stakeholders with differing interests can be asked to join to have an outsider's point of view

- Step 3 - Define the Project Scope: Pre-decide the VSM project scope that is: Should it be done for a specific step or for the whole process?

- Step 4 - Map Value Stream: Use VSM symbols to map the process into three segments, i.e., information flow, product flow, and time flow

- Step 5 - Add Process Metrics: Once the process is mapped, add relevant process performance metrics such as inventory held, cycle time, transfer time, etc.

- Step 6 - Create a Timeline: Create a process timeline with the calculation and addition of lead and cycle times

- Step 7 - Analyze Current Map: Perform Kaizen bursts to analyze the current process's VSM to identify overproduction, inventory, motion, defects, over-processing, waiting, and transport wastes

- Step 8 - Design Future Map: Use insights from Kaizen bursts for process improvements and design a future value stream map for the process

- Step 9 - Implement Map: Eventually, implement the future value stream map to achieve process efficiency

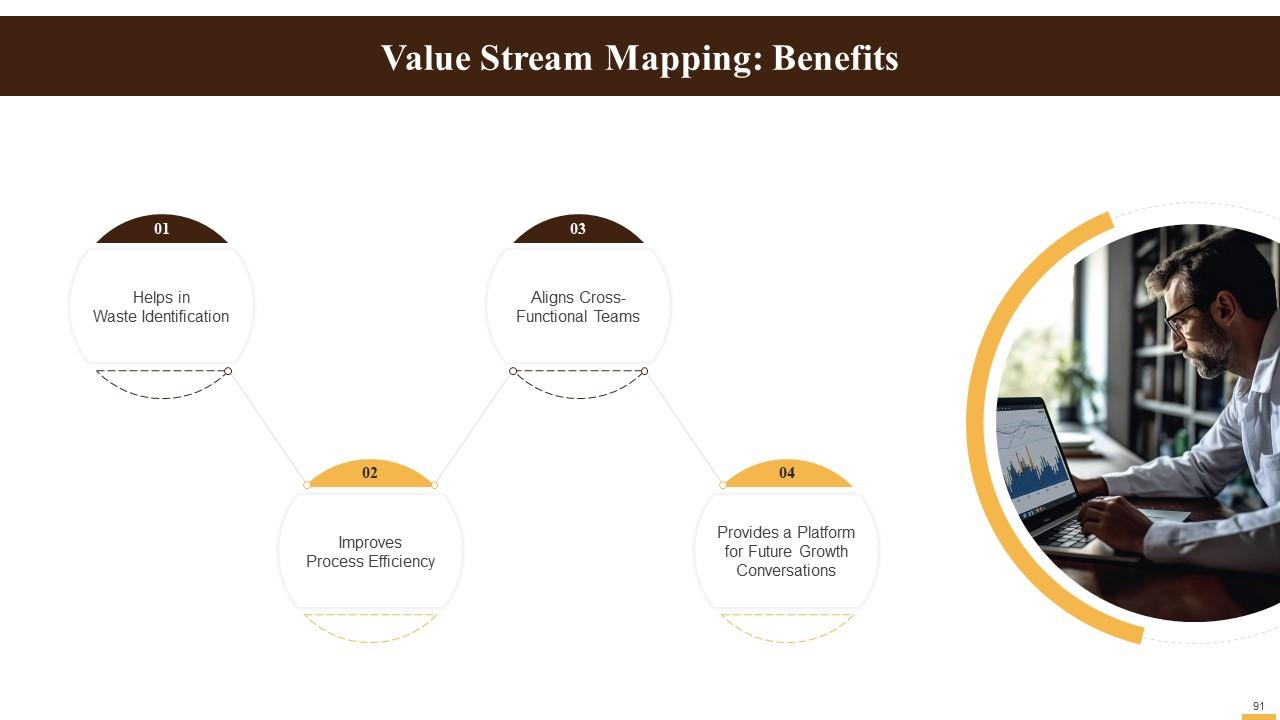

Slide 91

This slide lists the advantages of value stream mapping. It helps in waste identification, improves process efficiency, aligns cross-functional teams, and provides a platform for conversation on future growth.

Instructor’s Notes:

The benefits of VSM are:

- Helps in Waste Identification: With graphical illustration, VSM helps identify value addition and non-value addition activities. It helps pinpoint wastes that are occurring within the process

- Improves Process Efficiency: VSM labels and links information, product, and time flow to determine appropriate takt time, lead time, and cycle times between stages of the process for faster delivery of products to customers. It also helps in proper resource allocation to improve the system's quality

- Aligns Cross-Functional Teams: VSM team includes interdepartmental employees and stakeholders, which supports a shared understanding of the process. It helps focus on long-term goals instead of concentrating solely on their roles and responsibilities

- Provides a Platform for Future Growth Conversations: Post-implementation of the future state, VSM team with a greater understanding of the process, can devise plans for growth of the organization

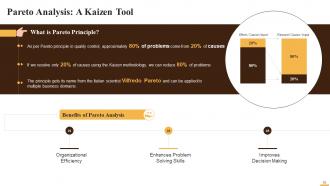

Slide 92

This slide is on the Pareto Principle which states that approximately 80% of problems come from 20% of causes. It lists improved organizational efficiency, enhanced problem-solving skills, and more skillful decision making as the three major advantages of the application of Pareto Analysis to organizational problems.

Instructor’s Notes:

The benefits of Pareto analysis are:

- Organizational Efficiency: Pareto analysis helps in ranking business problems on severity. Organizations achieve operational efficiency as employees are enabled/empowered to identify the root causes and spend time resolving the most significant problems to yield maximum organizational benefit

- Enhances Problem Solving Skills: Pareto analysis helps organize work-related problems into cohesive facts. Once facts are outlined, one can begin necessary planning to solve the problems

- Improves Decision Making: Pareto analysis helps measure and compare the impact of changes in an organization. It enables better preparation and improvements in decision-making for future changes

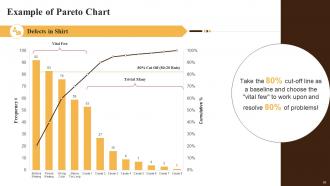

Slide 93

This slide visually presents the Pareto chart. It showcases the 80% cut-off line, vital few, and trivial many.

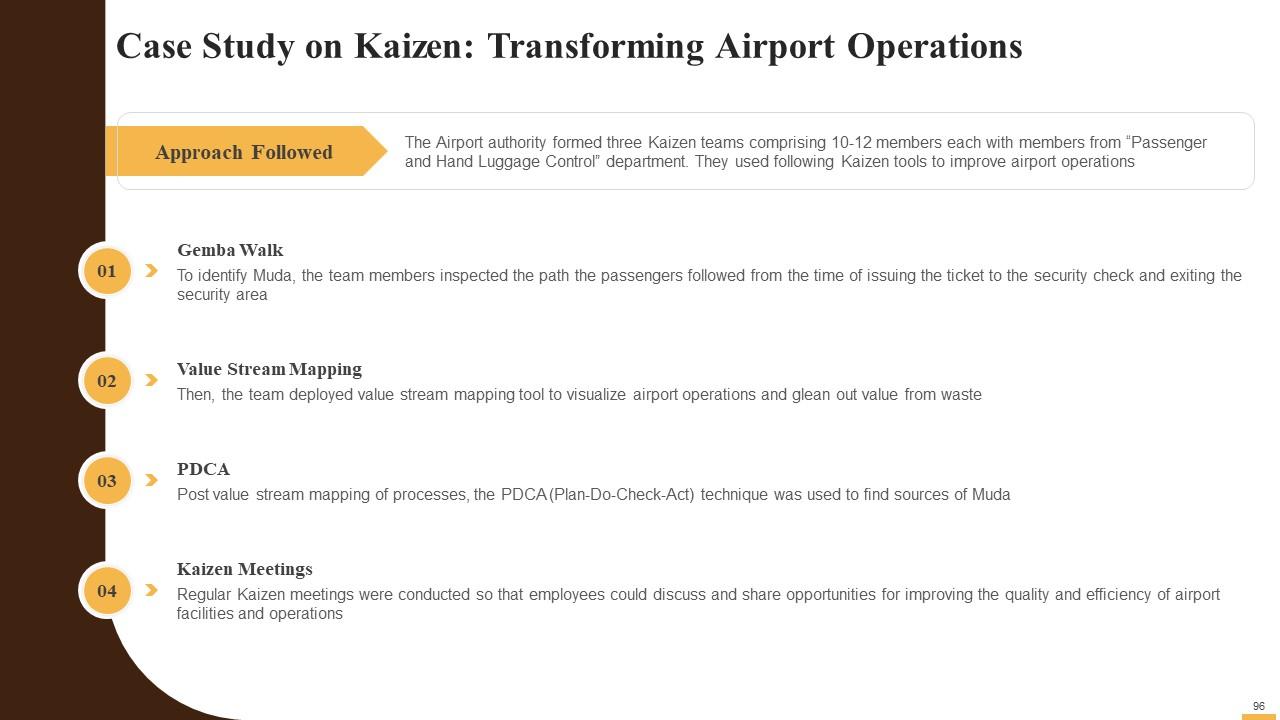

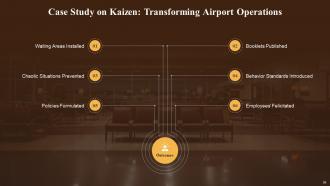

Slide 94 to 98

These slides includes a Kaizen case study on transforming Rome’s airports.

Kaizen Tools and Techniques Training Ppt with all 174 slides:

Use our Kaizen Tools and Techniques Training Ppt to effectively help you save your valuable time. They are readymade to fit into any presentation structure.

-

Wonderful templates design to use in business meetings.

-

Easily Understandable slides.