Artificial Intelligence In Supply Chain And Logistics Training Ppt

These slides highlight the growing need for implementing Artificial Intelligence in Supply Chain and Logistics as global supply networks become more complex. These also list its advantages along with its challenges.

These slides highlight the growing need for implementing Artificial Intelligence in Supply Chain and Logistics as global su..

- Google Slides is a new FREE Presentation software from Google.

- All our content is 100% compatible with Google Slides.

- Just download our designs, and upload them to Google Slides and they will work automatically.

- Amaze your audience with SlideTeam and Google Slides.

-

Want Changes to This PPT Slide? Check out our Presentation Design Services

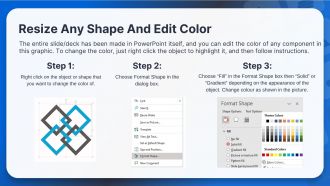

- WideScreen Aspect ratio is becoming a very popular format. When you download this product, the downloaded ZIP will contain this product in both standard and widescreen format.

-

- Some older products that we have may only be in standard format, but they can easily be converted to widescreen.

- To do this, please open the SlideTeam product in Powerpoint, and go to

- Design ( On the top bar) -> Page Setup -> and select "On-screen Show (16:9)” in the drop down for "Slides Sized for".

- The slide or theme will change to widescreen, and all graphics will adjust automatically. You can similarly convert our content to any other desired screen aspect ratio.

Compatible With Google Slides

Get This In WideScreen

You must be logged in to download this presentation.

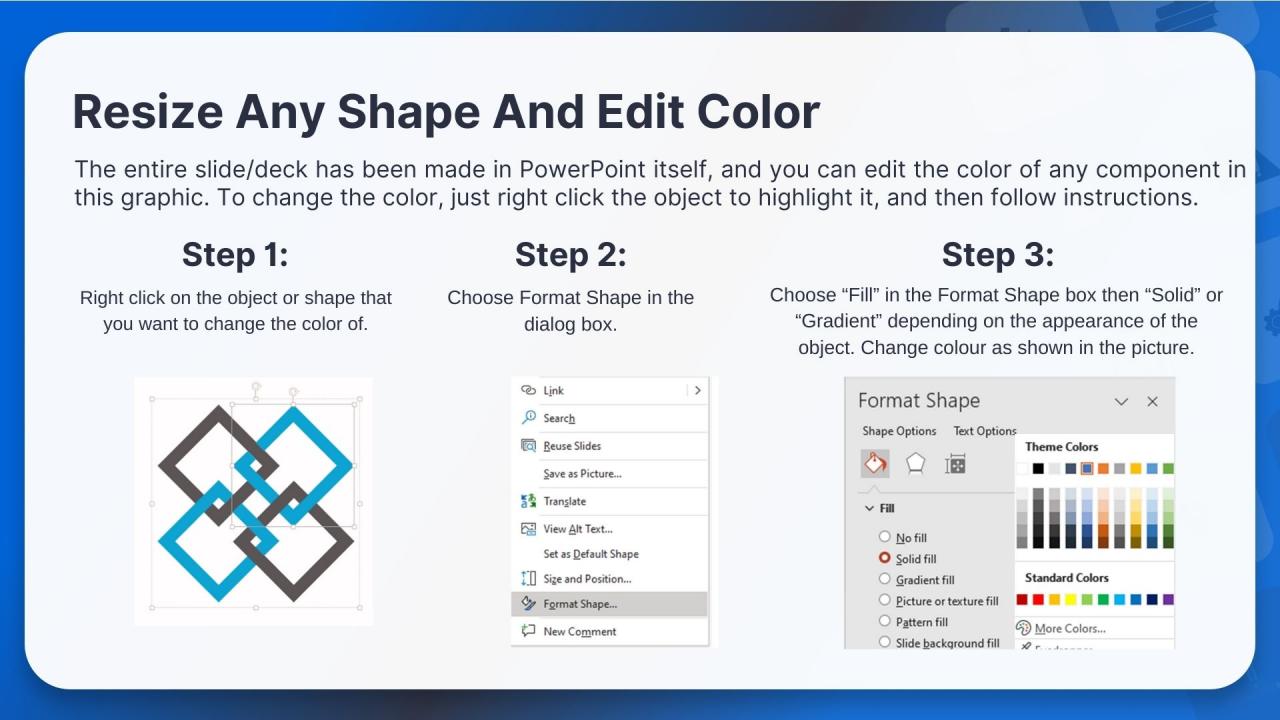

PowerPoint presentation slides

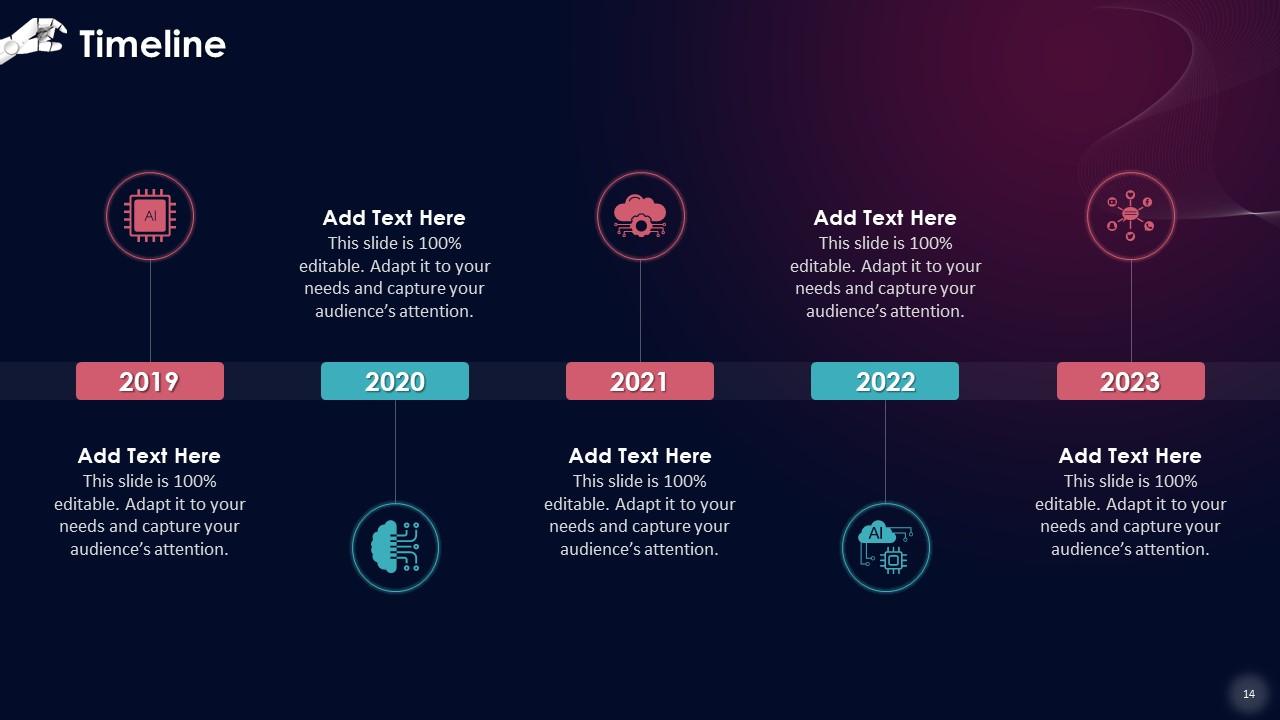

Presenting Artificial Intelligence in Supply Chain and Logistics. These slides are 100 percent made in PowerPoint and are compatible with all screen types and monitors. They also support Google Slides. Premium Customer Support available. Suitable for use by managers, employees, and organizations. These slides are easily customizable. You can edit the color, text, icon, and font size to suit your requirements.

People who downloaded this PowerPoint presentation also viewed the following :

Content of this Powerpoint Presentation

Slide 1

This slide introduces the growing need for implementation of Artificial Intelligence in Supply Chain and Logistics as global supply networks become more complex.

Slide 2

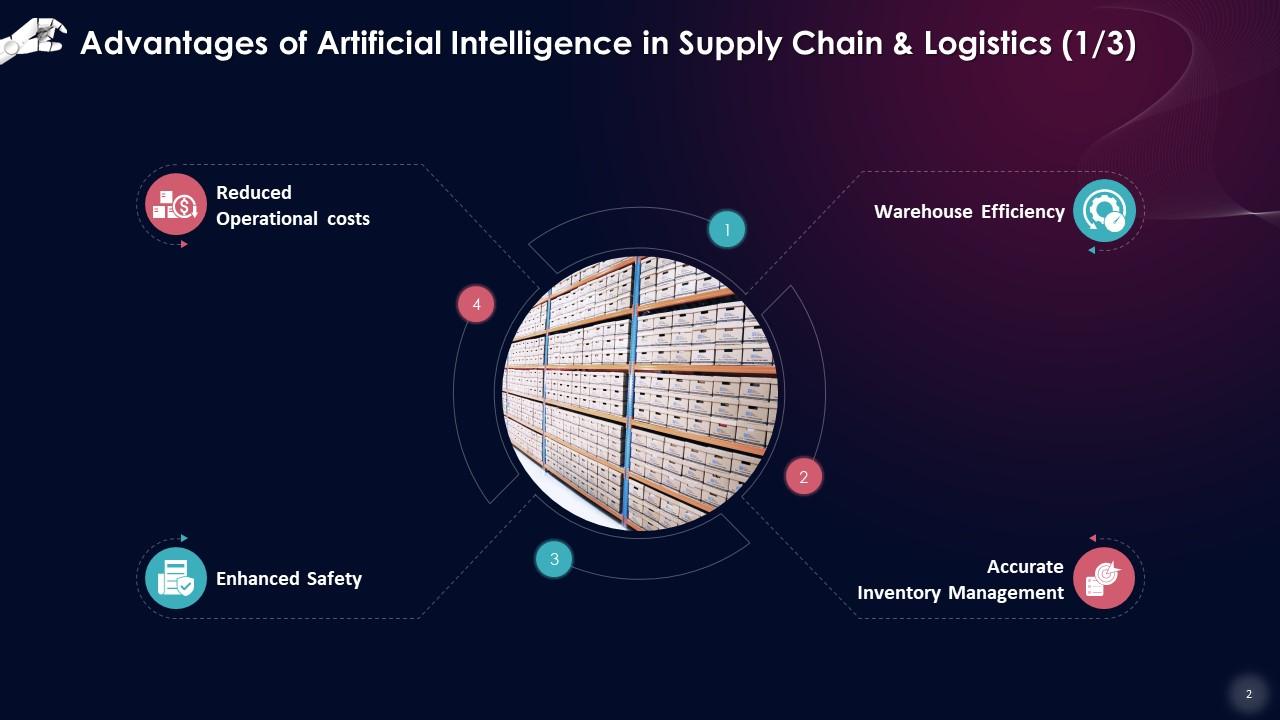

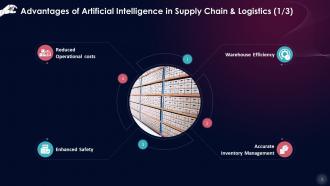

This slide lists advantages of Artificial Intelligence in Supply Chain and Logistics such as warehouse efficiency, accurate inventory management, enhanced safety, and reduced operational costs.

Instructor’s Notes:

- Warehouse Efficiency: An efficient warehouse is an important aspect of the supply chain. Automation can help with the prompt retrieval of items from warehouses and the smooth delivery of goods to customers. AI can also address a variety of warehouse problems faster and more precisely than humans, simplify complex procedures, and speed up work

- Accurate Inventory Management: Accurate inventory management can ensure appropriate flow of commodities in and out of a warehouse. AI-driven inventory management technologies can be highly effective due to their capacity to handle large amounts of data. These intelligent algorithms can evaluate and interpret large datasets quickly, offering timely supply and demand forecasting advice

- Enhanced Safety: AI-based automated technologies can help with better planning and warehouse management, along with staff and product safety. AI can also alert manufacturers of any potential dangers. It can keep records of stocking parameters and operations and provide feedback loops and preventative maintenance

- Reduced Operational Costs: This is a significant advantage of AI systems in the supply chain. Automated intelligent activities, from customer service to warehousing, can function error-free for longer periods of time, lowering the number of errors and workplace mishaps. Warehouse robots are faster and more accurate, resulting in improved output

Slide 3

This slide lists advantages of Artificial Intelligence in Supply Chain and Logistics such as planning & scheduling activities, on-time delivery, end-to-end visibility, and intelligent decision making.

Instructor’s Notes:

- Planning & scheduling Activities: AI in the supply chain enables the scheduling of more optimal alternatives as and when such disruptions occur by providing precise forecasts and quantification of expected results across schedule stages

- On-Time Delivery: AI technologies can reduce reliance on manual labor, making the entire process faster, safer, and more intelligent. This facilitates prompt delivery to the consumer. Traditional warehouse procedures are accelerated by automated technology, removing operational bottlenecks along the value chain allowing businesses to meet delivery targets

- End-to-End Visibility: With today's complicated supply chains, manufacturers need to gain total visibility into the whole supplier value chain with the least effort. A cognitive AI-driven automated platform provides a single virtualized data layer to reveal cause and effect, eliminate bottleneck procedures, and identify improvement opportunities

- Intelligent Decision Making: AI-powered supply chain optimization software magnifies crucial judgments by employing cognitive predictions and recommendations on optimal actions. This may aid in improving overall supply chain performance

Slide 4

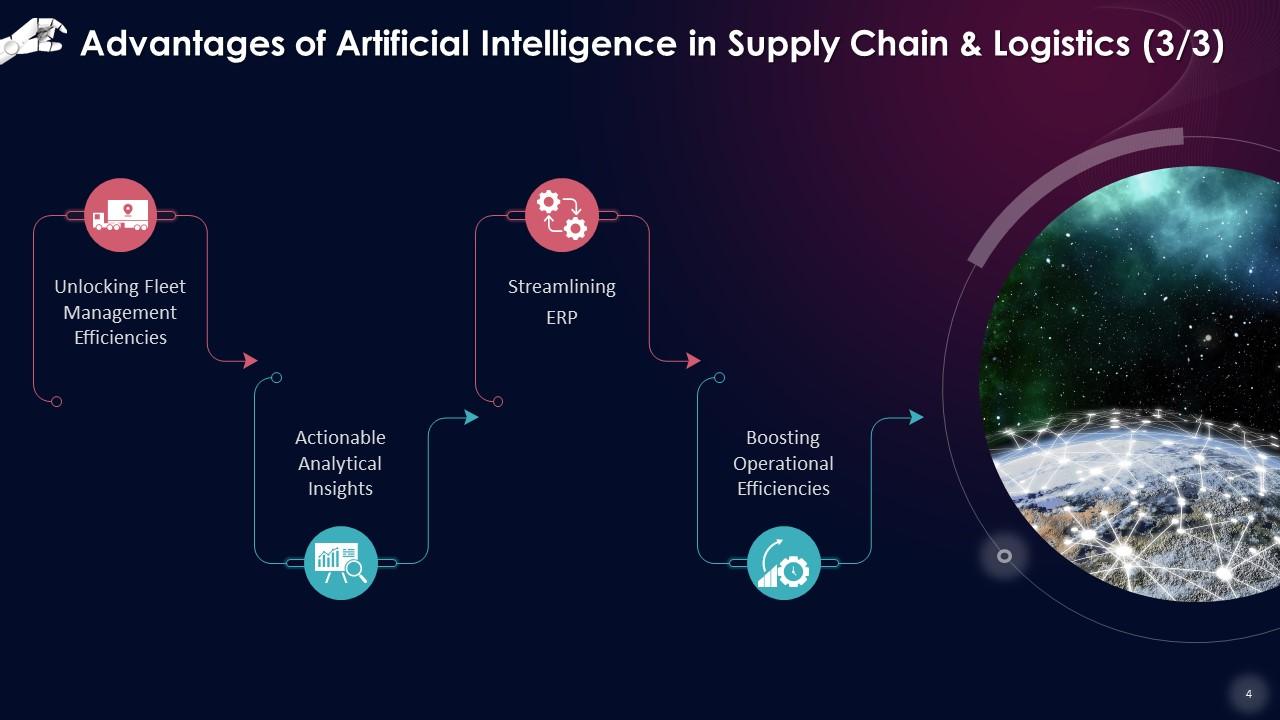

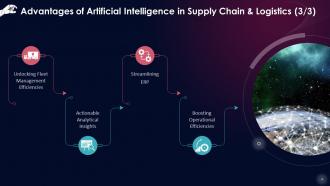

This slide lists the advantages of Artificial Intelligence in Supply Chain and Logistics such as unlocking fleet management efficiencies, actionable analytical insights, streamlining Enterprise Resource Planning (ERP), and boosting operational efficiencies.

Instructor’s Notes:

- Unlocking Fleet Management Efficiencies: Fleet management operation is one of the most undervalued components of the supply chain. Fleet managers are in charge of maintaining the continuous flow of commerce by orchestrating the critical relationship between the provider and the consumer. AI in supply chain and logistics allows for real-time tracking, which helps with reducing unplanned fleet downtime, improving fuel efficiency, and detecting and avoiding obstacles

- Actionable Analytical Insights: Several firms today lack important actionable data that may be used to make decisions that meet expectations quickly and efficiently. Cognitive automation that uses AI can sift through enormous volumes of scattered data to find patterns and quantify tradeoffs on a large scale, far better than traditional systems can

- Streamlining ERP: According to research done by Panorama Consulting, "Over 63% of manufacturing organizations surpass their ERP budgets, with average installation costs exceeding $3 million." Supply chain managers have complex business processes since they deal with heterogeneous purchasing, procurement, and logistics across worldwide supply networks. AI in supply chain and logistics helps in streamlining the ERP framework, making it future-ready and intelligently connecting people, processes, and data

- Boosting Operational Efficiencies: Radical efficiencies can be obtained when supply chain components become crucial nodes for tapping data and powering machine learning algorithms. On-demand trends, product life cycles, and stacking the product against the competition can influence price change. This information is invaluable and may be used to improve the supply chain planning process and increase efficiencies

Slide 5

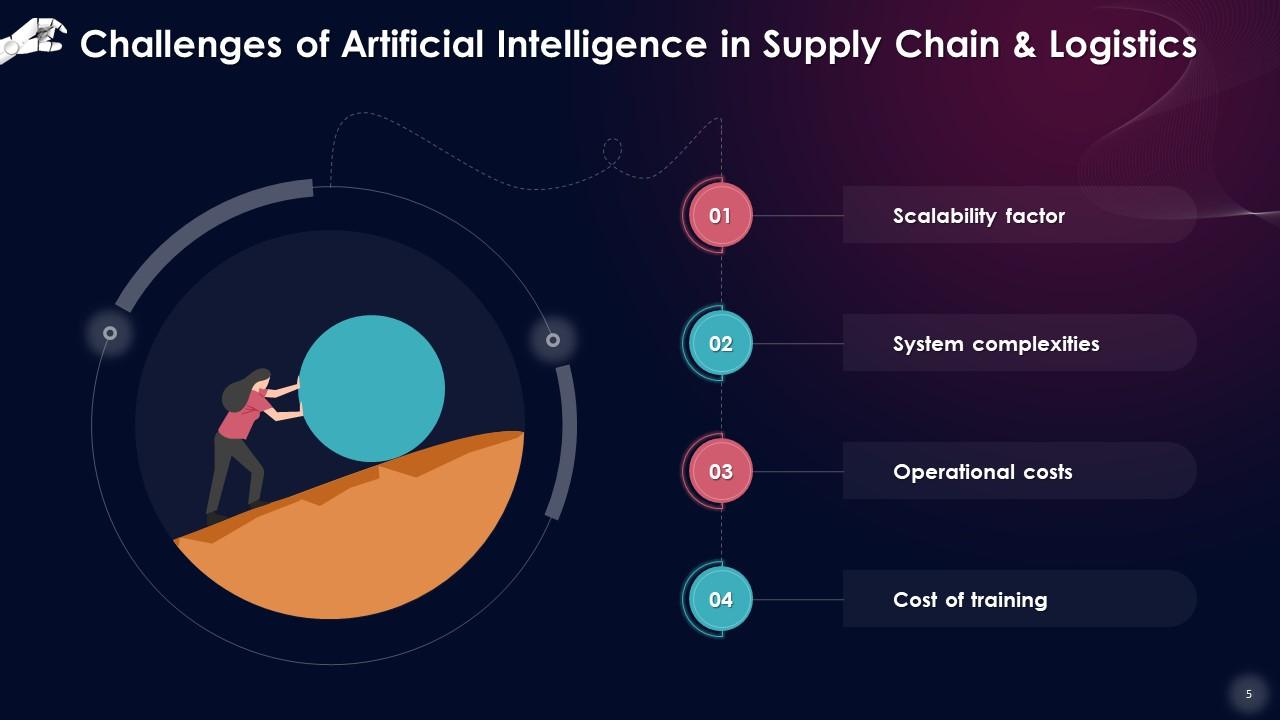

This slide highlights the challenges of AI in Supply Chain and Logistics such as the scalability factor, system complexities, operational costs, and cost of training.

Instructor’s Notes:

- Scalability Factor: The problem is the initial start-up users/systems required for the AI to learn the patterns and be more impactful and effective, even though most AI and cloud-based technologies are quite scalable

- System Complexities: AI systems are typically cloud-based, requiring a large amount of bandwidth to fuel the system. Operators may also need specialized gear to access AI capabilities, and the cost of AI-specific technology can be too expensive for many supply chain partners

- Operational Costs: An AI-controlled machine has a complex network of individual processors that need periodic maintenance and replacement. The problem is that the operational investment could be significant due to the potential cost and energy involved

- Cost of Training: Like any other new technology solution, training necessitates a significant investment of both time and money. During the integration phase, supply chain partners will need to collaborate with AI providers to develop a training solution that is both effective and cost-efficient

Artificial Intelligence In Supply Chain And Logistics Training Ppt with all 21 slides:

Use our Artificial Intelligence In Supply Chain And Logistics Training Ppt to effectively help you save your valuable time. They are readymade to fit into any presentation structure.

-

Enough space for editing and adding your own content.

-

It’s really cool, and you can find pretty much everything you could need for your work or school.