Automation In Manufacturing IT Powerpoint Presentation Slides V

IT plays a very significant role in the manufacturing industry. Grab our insightfully designed Automation in Manufacturing IT template. It gives a brief idea about the evolution of the manufacturing industry from 1.0 to 4.0. The PPT includes the technologies used in this industry to overcome production issues. Our AI in manufacturing deck covers the various technologies used in manufacturing industries. These include Automation Robotics, Artificial Intelligence AI, Explainable AI, etc. In addition, the PPT contains the introduction and features of the manufacturing industry. Additionally, our Smart manufacturing module exhibits market size, share, and global spending. It further incorporates application areas, types, impact, working, and safety measures of every technology used. Furthermore, it includes cyber securitys role in smart manufacturing, a 30 60 90 days plan, and a training program for cyber security awareness among employees. Our Smart Manufacturing template caters to the training budget and pricing for technologies used. It also exhibits a timeline and a roadmap to implement IT in the manufacturing industry. Moreover, this IoT in Manufacturing deck comprises a predictive analytics dashboard to track manufacturing operations. Get access now.

You must be logged in to download this presentation.

Impress your

Impress your audience

Editable

of Time

PowerPoint presentation slides

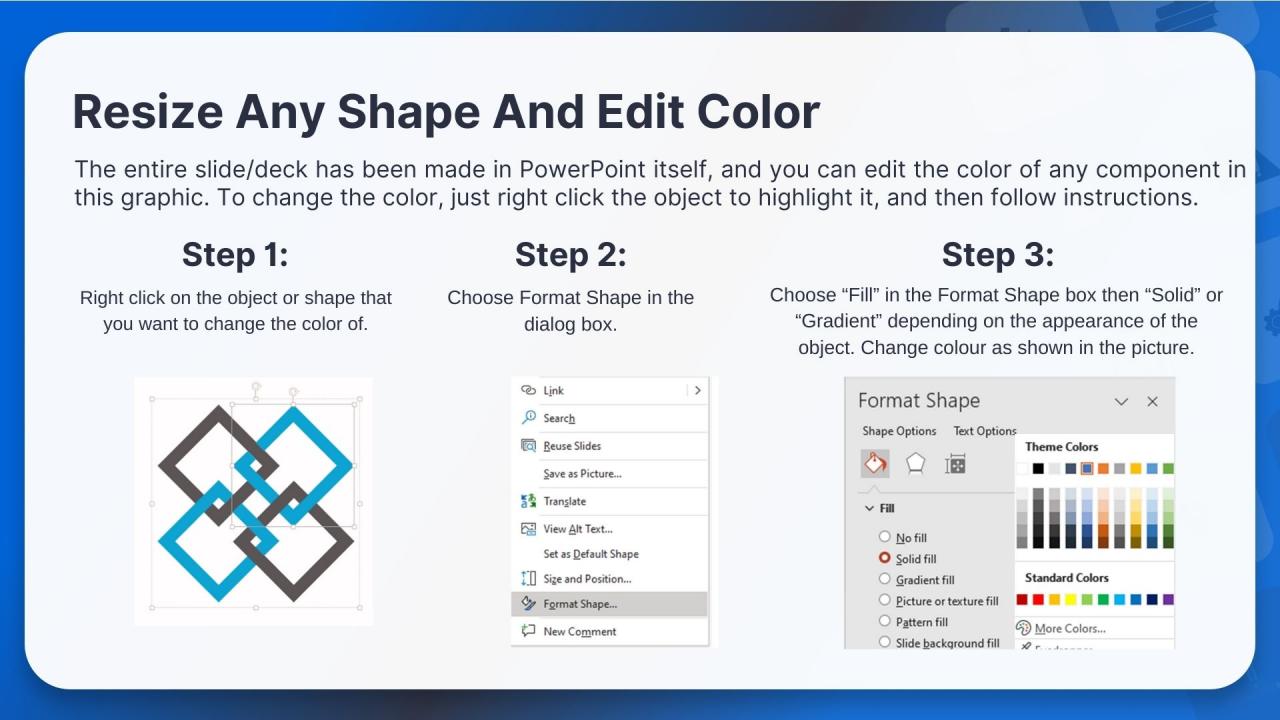

This complete deck covers various topics and highlights important concepts. It has PPT slides which cater to your business needs. This complete deck presentation emphasizes Automation In Manufacturing IT Powerpoint Presentation Slides V and has templates with professional background images and relevant content. This deck consists of total of ninety two slides. Our designers have created customizable templates, keeping your convenience in mind. You can edit the color, text and font size with ease. Not just this, you can also add or delete the content if needed. Get access to this fully editable complete presentation by clicking the download button below.

People who downloaded this PowerPoint presentation also viewed the following :

Content of this Powerpoint Presentation

Slide 1: This slide displays the title Automation in Manufacturing (IT).

Slide 2: This slide displays the title Agenda.

Slide 3: This slide exhibit table of content.

Slide 4: This slide exhibit table of content.

Slide 5: This slide showcase table of content that is to be discuss further.

Slide 6: This slide depicts the evolution of manufacturing from industry 1.0 to industry 4.0.

Slide 7: This slide showcase table of content that is to be discuss further.

Slide 8: This slide represents the industrial robot shipment prediction for the 3rd and 2nd editions from 2018 to 2024.

Slide 9: This slide represents the areas where robots can be used in the manufacturing process to save time, effort, and money.

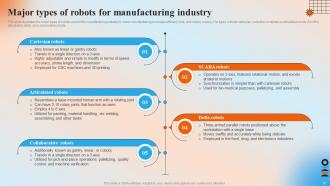

Slide 10: This slide illustrates the major types of robots used in the manufacturing industry to make manufacturing processes efficient, time, and money-saving.

Slide 11: This slide outlines the applications of robots in material handling chores.

Slide 12: This slide talks about robotic welding, and because of the diversity of gear available, robots can accommodate a wide range of welding procedures.

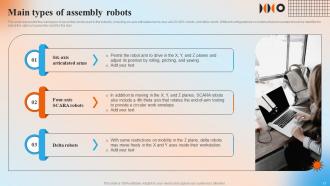

Slide 13: This slide represents the main types of assembly robots used in the industry, including six-axis articulated arms, four-axis SCARA robots, and delta robots.

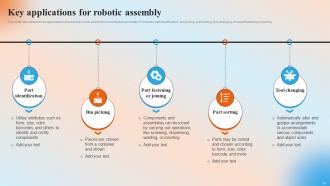

Slide 14: This slide describes the key applications of assembly robots used in the manufacturing industry.

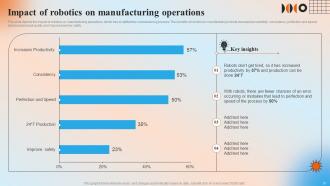

Slide 15: This slide depicts the impact of robotics on manufacturing operations, which has simplified the manufacturing process.

Slide 16: This slide showcase table of content that is to be discuss further.

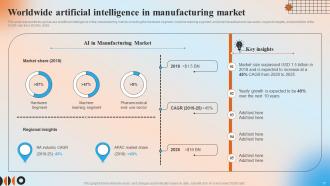

Slide 17: This slide represents the global use of artificial intelligence in the manufacturing market.

Slide 18: This slide depicts the features of artificial intelligence for the manufacturing industry.

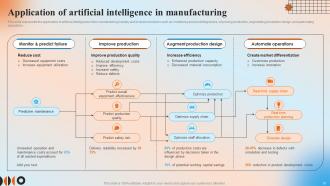

Slide 19: This slide represents the application of artificial intelligence in the manufacturing industry and includes functions.

Slide 20: This slide depicts the impact of artificial intelligence on manufacturing operations.

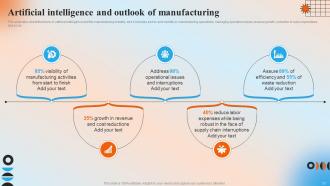

Slide 21: This slide talks about the future of artificial intelligence and the manufacturing industry.

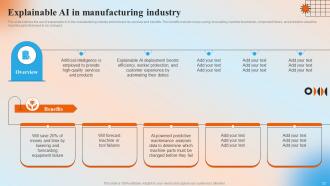

Slide 22: This slide outlines the use of explainable AI in the manufacturing industry and includes its overview and benefits.

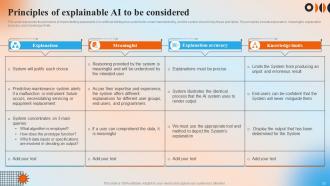

Slide 23: This slide represents the principles of implementing explainable AI in artificial intelligence systems for smart manufacturing.

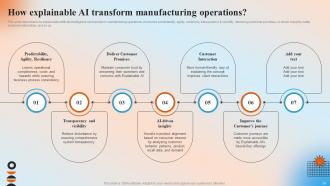

Slide 24: This slide describes how explainable artificial intelligence can transform manufacturing operations.

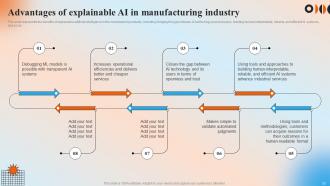

Slide 25: This slide represents the benefits of explainable artificial intelligence in the manufacturing industry.

Slide 26: This slide showcase table of content that is to be discuss further.

Slide 27: This slide depicts the global spending on the industrial internet of things technologies from 2019 to 2027.

Slide 28: This slide describes the main adoption drivers for the industrial internet of things solutions.

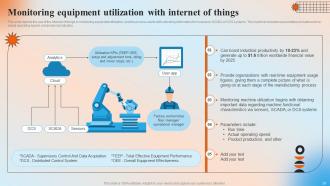

Slide 29: This slide depicts the use of the internet of things in monitoring equipment utilization, and the process starts with collecting information.

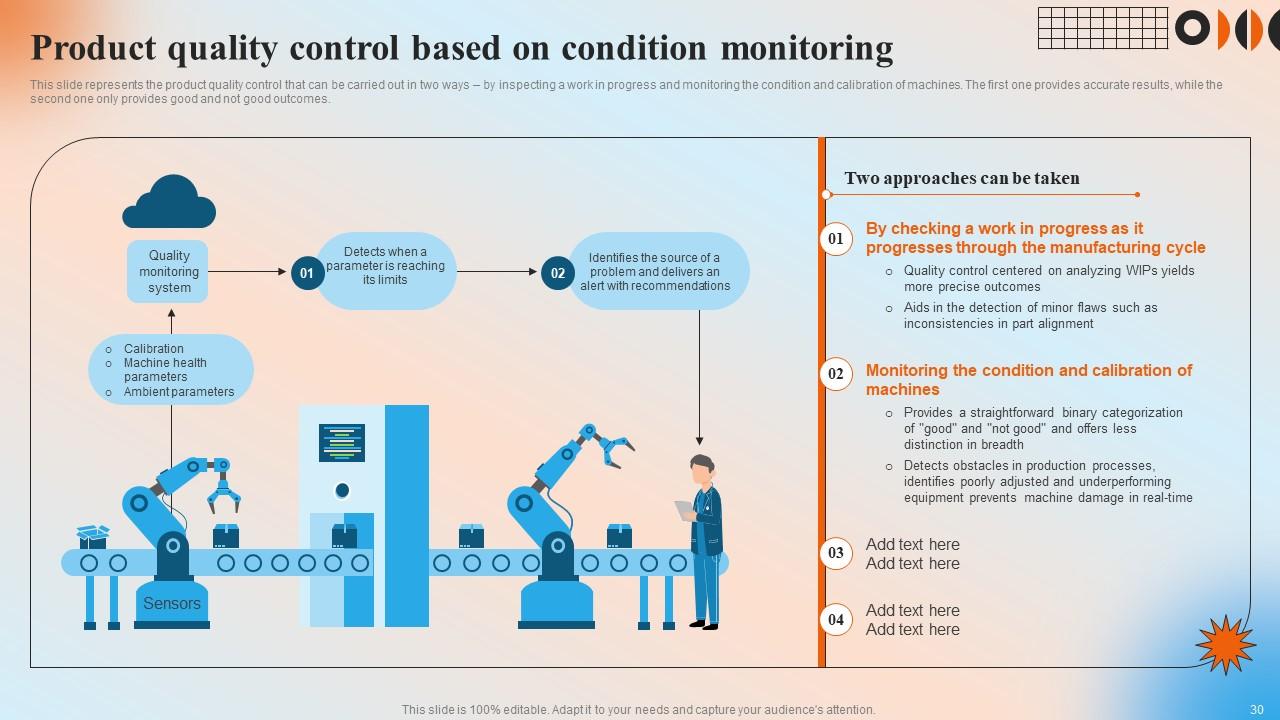

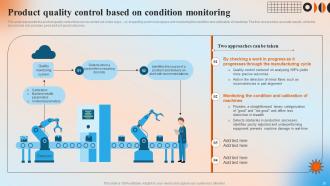

Slide 30: This slide represents the product quality control that can be carried out in two ways – by inspecting a work in progress and monitoring the condition and calibration.

Slide 31: This slide describes monitoring workers’ safety through the internet of things and wearable sensors to prevent accidents or falls.

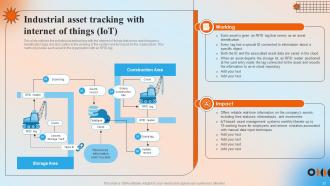

Slide 32: This slide outlines the industrial asset tracking with the internet of things that works radio frequency identification tags.

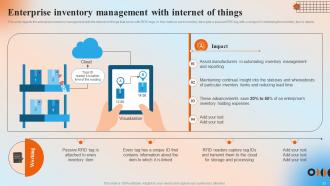

Slide 33: This slide depicts the enterprise inventory management with the internet of things that works with RFID tags.

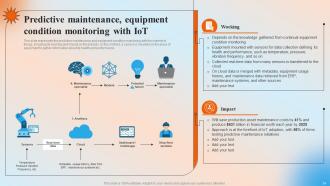

Slide 34: This slide represents the predictive maintenance and equipment condition monitoring with the internet of things, including its working and impact on the industry.

Slide 35: This slide talks about optimizing supply chain logistics and warehouse operations with the internet of things in the manufacturing industry.

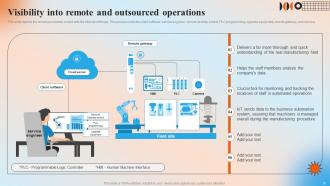

Slide 36: This slide depicts the remote production control with the internet of things.

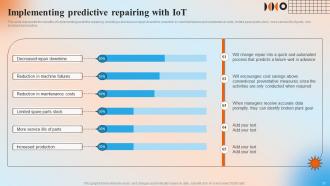

Slide 37: This slide represents the benefits of implementing predictive repairing.

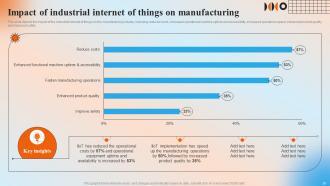

Slide 38: This slide depicts the impact of the industrial internet of things on the manufacturing industry.

Slide 39: This slide showcase table of content that is to be discuss further.

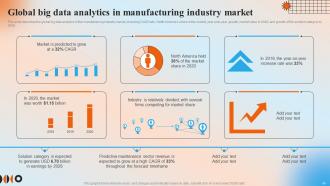

Slide 40: This slide describes the global big data analytics in the manufacturing industry market.

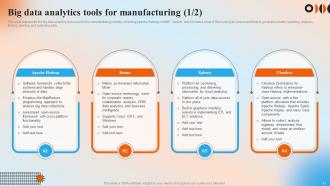

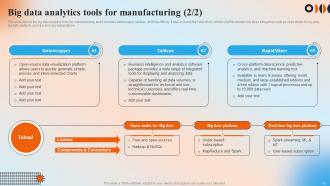

Slide 41: This slide represents the big data analytics tools used in the manufacturing industry.

Slide 42: This slide depicts the big data analytics tools for manufacturing, and it includes datawrapper, tableau, and RapidMiner.

Slide 43: This slide represents big data analytics applications in the manufacturing industry.

Slide 44: This slide showcase table of content that is to be discuss further.

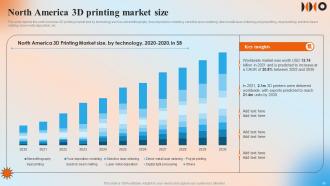

Slide 45: This slide depicts the north American 3D printing market size by technology.

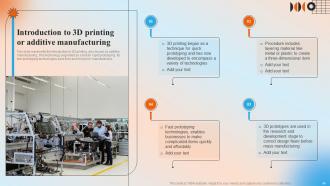

Slide 46: This slide represents the introduction to 3D printing, also known as additive manufacturing.

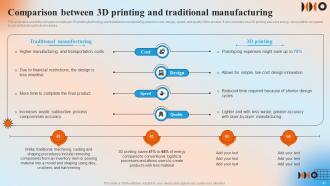

Slide 47: This slide talks about the comparison between 3D printing technology and traditional manufacturing based on cost, design, speed, and quality of the product.

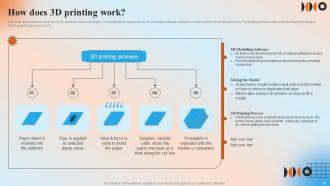

Slide 48: This slide represents the working of a 3D printer to make a prototype.

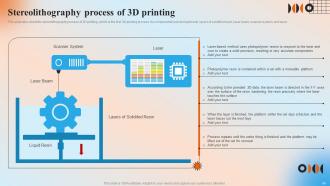

Slide 49: This slide talks about the stereolithography process of 3D printing, which is the first 3D printing process.

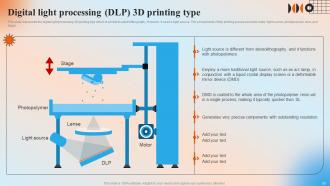

Slide 50: This slide represents the digital light processing 3D printing type which is similar to stereolithography.

Slide 51: This slide describes the laser sintering or laser melting 3D printing technique.

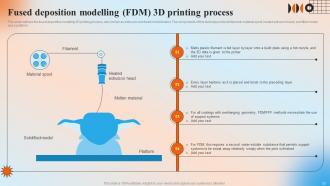

Slide 52: This slide outlines the fused deposition modeling 3D printing process, also known as extrusion and freeform fabrication.

Slide 53: This slide talks about the inkjet binder jetting 3D printing process, including its working and benefits.

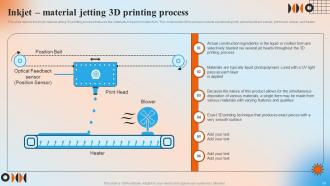

Slide 54: This slide depicts the inkjet material jetting 3D printing process that uses the materials in liquid or molten form.

Slide 55: This slide describes the selective deposition lamination 3D printing process that builds parts layer by layer on regular copier paper.

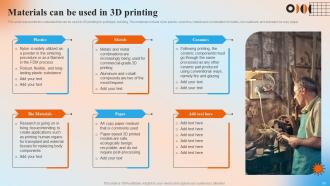

Slide 56: This slide represents the materials that can be used in 3D printing for prototype building.

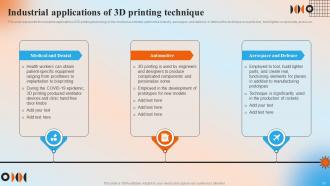

Slide 57: This slide represents the industrial applications of 3D printing technology in the medical and dental, automotive industry, aerospace, and defence.

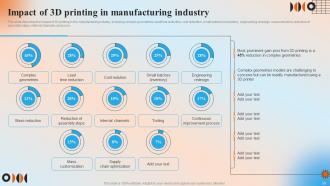

Slide 58: This slide describes the impact of 3D printing in the manufacturing industry.

Slide 59: This slide showcase table of content that is to be discuss further.

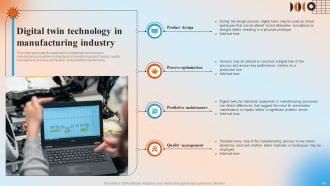

Slide 60: This slide represents the application of digital twin technology in manufacturing industries by depicting.

Slide 61: This slide represents the application of digital twin in supply chain management to predict the quality of packaging materials, improve shipment security.

Slide 62: This slide depicts the impact of the digital twin on manufacturing operations that include innovation catalyst and cost reduction.

Slide 63: This slide showcase table of content that is to be discuss further.

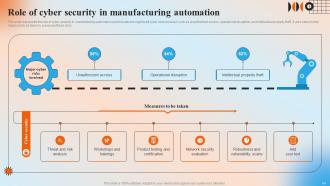

Slide 64: This slide represents the role of cyber security in manufacturing automation and includes the significant cyber risks.

Slide 65: This slide describes the first 30 days of managing cyber security in the manufacturing operations plan.

Slide 66: This slide represents the next 60 days of managing cyber security in the manufacturing operations plan.

Slide 67: This slide depicts the next 90 days of managing cyber security in the manufacturing operations plan.

Slide 68: This slide outlines the employee awareness training budget for the financial year 2023.

Slide 69: This slide showcase table of content that is to be discuss further.

Slide 70: This slide represents the training program for technologies used in the manufacturing industry.

Slide 71: This slide talks about the pricing for technologies used in the manufacturing industry.

Slide 72: This slide showcase table of content that is to be discuss further.

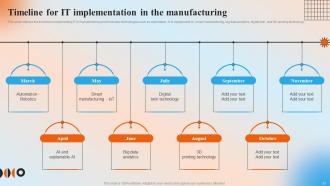

Slide 73: This slide outlines the timeline to implementing IT in manufacturing and it includes technologies such as automation, AI & explainable AI, smart manufacturing.

Slide 74: This slide showcase table of content that is to be discuss further.

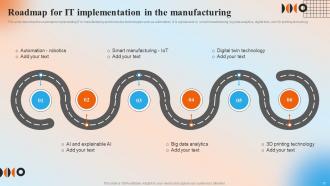

Slide 75: This slide describes the roadmap to implementing IT in manufacturing and it includes technologies.

Slide 76: This slide showcase table of content that is to be discuss further.

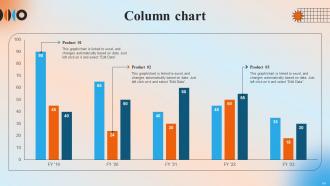

Slide 77: This graph/chart is linked to excel, and changes automatically based on data.

Slide 78: This is the icons slide.

Slide 79: This slide presents title for additional slides.

Slide 80: Services 40% Product 60% Future trend Services 20% Product 80% Current mix New business model for service business This slide describes the new business model for service business use case for the internet of things, including its impact on the product and service ratio of the company. This slide is 100% editable. Adapt it to your needs and capture your audience's attention. 80 Key insights Income mix for products and services will be shifted from 80%: 20% to 60%: 40% After-sales services and remote machine breakdowns diagnosis will aid decision-making and speed up the deployment of the necessary resources and spare parts Changes in warranty, support, and travel will result in less downtime and lower costs Add your text Add your text Add your text Add your text

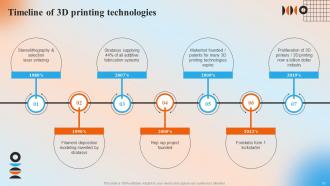

Slide 81: Timeline of 3D printing technologies 81 This slide is 100% editable. Adapt it to your needs and capture your audience's attention. 01 Stereolithography & selection laser sintering 1980’s 02 Filament deposition modeling invented by stratasys 1990’s 07 Proliferation of 3D printers / 3D printing now a billion dollar industry 2019’s 03 Stratasys supplying 44% of all additive fabrication systems 2007’s 04 Rep rap project founded 2005’s 05 Makerbot founded / patents for many 3D printing technologies expire 2009’s 06 Formlabs form 1 kickstarter 2012’s

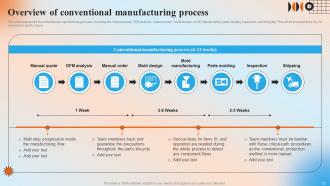

Slide 82: Overview of conventional manufacturing process 82 This slide represents the conventional manufacturing process, including the manual quote, DFM analysis, manual order, model design, mold manufacturing, parts molding, inspection, and shipping. This whole process takes 6 to 12 weeks from start to finish. Multi-step progression inside the manufacturing flow Add your text Add your text Team members track and guarantee the precautions throughout the part's lifecycle Add your text Various tests for form, fit, and operation are needed during the whole process to detect any component flaws Add your text Team members must be familiar with these critical-path procedures as the conventional production method is more manual Add your text Conventional manufacturing process (6-12 weeks) Manual quote DFM analysis Manual order Mold design Mold manufacturing Parts molding Inspection Shipping 1 Week 3-8 Weeks 2-3 Weeks This slide is 100% editable. Adapt it to your needs and capture your audience's attention.

Slide 83: This slide represents the challenges with traditional manufacturing systems.

Slide 84: This slide exhibits yearly profits stacked column charts for different products.

Slide 85: This slide showcase the title Meet our team.

Slide 86: This slide presents your company's vision, mission and goals.

Slide 87: This slide exhibits ideas generated.

Slide 88: This slide exhibits yearly timeline of company.

Slide 89: This slide presents Quotes.

Slide 90: This slide display Venn diagram.

Slide 91: This slide showcase SWOT analysis.

Slide 92: This is thank you slide & contains contact details of company like office address, phone no., etc.

Automation In Manufacturing IT Powerpoint Presentation Slides V with all 97 slides:

Use our Automation In Manufacturing IT Powerpoint Presentation Slides V to effectively help you save your valuable time. They are readymade to fit into any presentation structure.

-

Graphics are very appealing to eyes.

-

Innovative and attractive designs.