Five years ago, in 2017, the fidget spinner emerged as THE rage around the world in double quick time, only to fall 10 times faster off the popularity charts.

In fact, retailers reported that no one was taking these away, even if offered for free.

What happened to the fidget spinner?

In all probability, the makers did not anticipate such huge demand and ran out of stock; when they finally made in enough quantities, people got tired and shunned the fidget spinners.

This fact-based short story has an important lesson for manufacturers: planning a calendar and developing the capability to make things Just-In-Time.

Makers of things, especially solid, brick-and-mortar products, must implement just-in-time (JIT) manufacturing to avoid meeting the same fate as the fidget spinner.

This is especially important as the manufacturing that we are referring to here is typical of primary goods like steel, cloth, etc, without which other products cannot be made. In the business cycle, there is always a cycle in operation, and things are interlinked in ways that we cannot even imagine.

What is JIT?

Just-in-time manufacturing is a system where materials are only delivered when needed to avoid waste and excessive inventory. This type of manufacturing requires careful planning, coordination between suppliers and manufacturers, and a JIT Manufacturing System in place. JIT systems ensure that all material is delivered on time and that production schedules are met.

In just-in-time manufacturing, items are produced only when an order is placed for them. This means that there is no need to store large quantities of finished goods.

Implementing just-in-time manufacturing can be challenging, but the benefits are significant. JIT manufacturing can help improve quality control, reduce waste, and increase efficiency. When done correctly, JIT manufacturing can help to save time and money.

If you are considering implementing a just-in-time manufacturing system, there are a few things to keep in mind. First, you will need to plan and coordinate with your suppliers. Second, you will need to have a JIT system in place. And third, you will need to monitor your progress and make course corrections as needed.

With careful planning and execution, just-in-time manufacturing can be a great way to improve your manufacturing process. It’s a team effort, and everyone needs to be on board. A PowerPoint Presentation is an easy solution to disseminating the needed information. We have created and curated 10 impressive PowerPoint Templates from world-class research papers and case studies to help you out.

Template 1: Just in Time PowerPoint Bundles

Whether you're pitching to potential clients or delivering a critical report, this PPT Deck will help you get the job done. It covers the delivery approach, manufacturing process flow, workflow, and more for the JIT system. Download it by clicking the link below to implement the JIT philosophy.

Template 2: JIT Manufacturing Optimization Management

This PowerPoint Set is designed to deliver significant improvements in productivity and quality. It covers the JIT implementation for manufacturing optimization, meeting customer requirements, quality and design, etc. Get it right away.

Template 3: JIT Manufacturing System to Improve Production

This PPT slide presents a lean manufacturing system that uses JIT techniques to streamline production. The steps included are production line arrangement, supplier relationship, facility layout, etc. Use it now to optimize the manufacturing process.

Template 4: JIT Concept for Organization Manufacturing Process Optimization

This PowerPoint theme illustrates the benefits of the JIT philosophy. It covers advantages such as reliable process flow, quality control, waste reduction, and many more in a captivating manner. Use this PPT Layout to educate the company on JIT and ensure information retention.

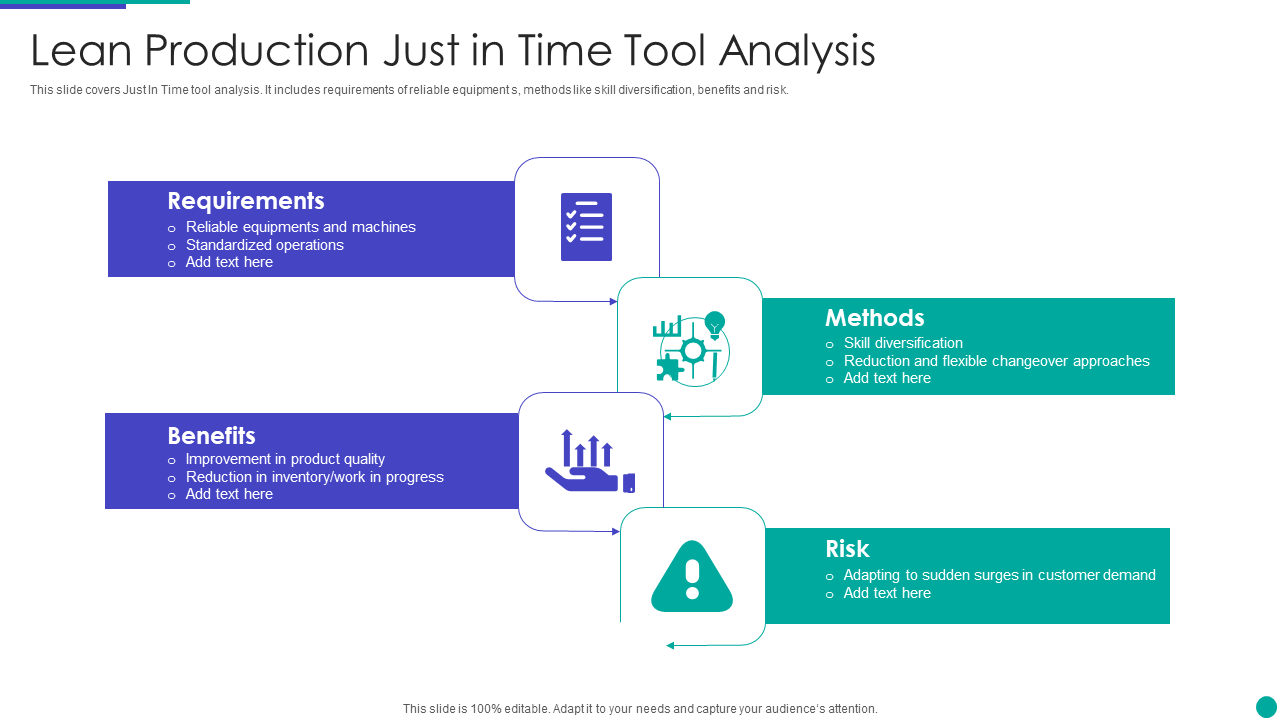

Template 5: Lean Production Just-in-Time Tool Analysis

This PPT Preset showcases the requirements, methods, benefits, and risks of implementing a lean manufacturing process. Download it now.

Template 6: JIT Structure for Maintaining Suppliers' Relationship and Production Line

If you're looking for a way to manage your production line and keep your supplier relationships strong, this JIT PowerPoint flowchart is the perfect guide. With this slide, you can track inventory levels, schedule production, and monitor supplier performance all in one place. Get it now.

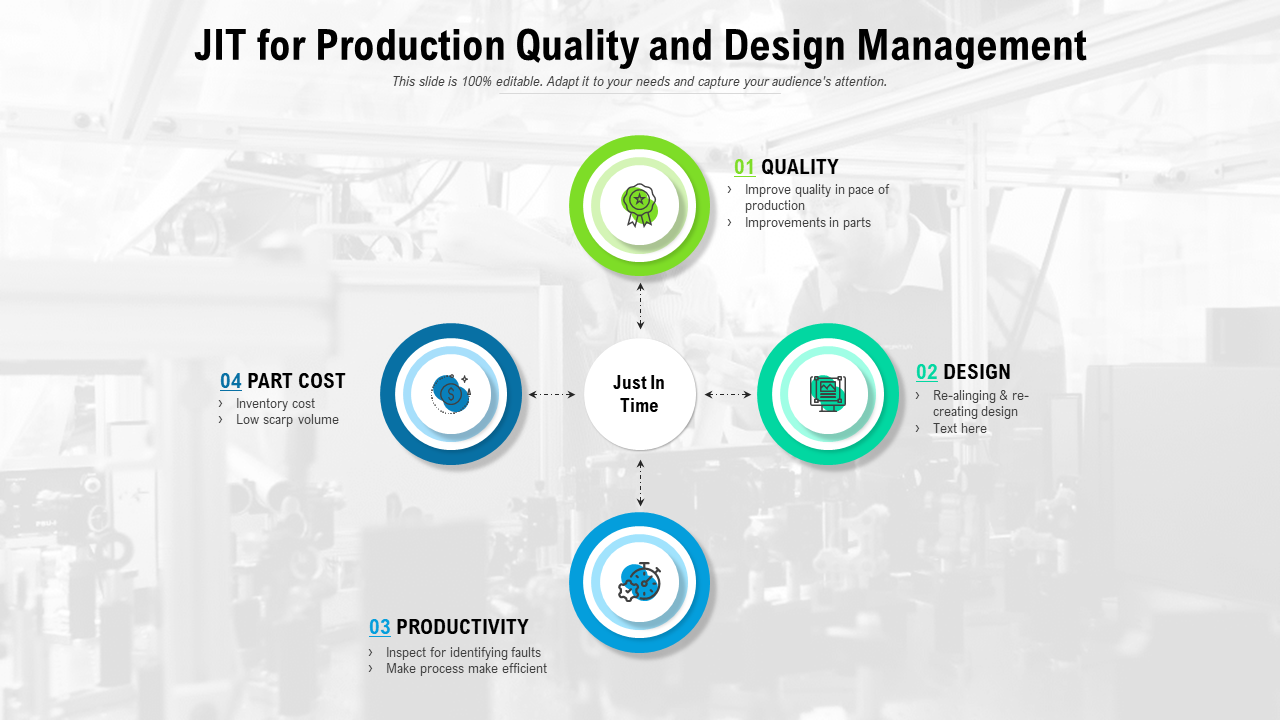

Template 7: JIT for Production Quality and Design Management

This PPT slide gives you parameters for implementing JIT with benefits listed along each of these. The parameters are quality, design, productivity, and para cost. It helps managers gain insights into all aspects of production, identify bottlenecks and areas for improvement, and track progress over time. Get it now.

Template 8: Lean Management Vs. JIT Presentation Slide

This PPT Tabulated Theme is your go-to template to present comparisons and differences between lean manufacturing and JIT manufacturing philosophies. Contrast the two techniques against activities such as inventory level, suitability, process waste, and many more. Get it now and ask your supply chain managers which process is the best for you.

Template 9: Lean Management and JIT Production

This PPT slide showcases how Lean and JIT come together to achieve goals in the company. It presents the ultimate goal that the company aims for, with several smaller goals aligning with the bigger achievement. This presentation guide also gives you the steps involved in JIT implementation.

Template 10: JIT for Fulfilling Customer Requirements

This PowerPoint Layout simplifies the role of JIT in the entire process, including the suppliers, manufacturing, customers, and more. It presents the flow of products starting with a need raised by customers as the catalyst to the process. Get it now.

JIT allows a manufacturer to work smart, not necessarily harder and benefits everyone in the supply chain. Make good use of our templates and turn your business into a well-oiled machine.

FAQs on Just-in-Time Manufacturing

1. What are the five 5 principles of JIT manufacturing?

The Five Principles of JIT Manufacturing are:

- Eliminate waste, as there is no unnecessary production involved, and resources are conserved with no need to maintain large inventory levels

- Built-in-quality

If you know you are producing to a demand that will materialize to the last unit, you can make better products and ensure premium quality in each unit in whatever you are producing

- Deliver on time

With your target set, you can deliver at the exact time it is needed. An instance of this from our daily lives is the grocer giving you fresh supplies of your favorite fruit at your chosen time. JIT aims to ensure that your product should spend as little time as possible on the shelves of a retailer or a wholesaler. It should fly off the shelves and be replaced with agility as well.

- Do it right the first time

In manufacturing, there is really no scope for tinkering with the product once it has been made. Get your product right, and ensure you get the demand forecast right.

- Continuously improve processes

With JIT, the key is to use the luxury of time that having no or negligible inventory gives you to improve your products constantly. For instance, make proper batches of fast-moving products to replace and send them to channel partners in a single go, etc.

2. What are the risks of JIT?

When it comes to just-in-time (JIT) manufacturing, there are a few potential risks that businesses should be aware of.

First, JIT relies heavily on efficient and accurate forecasting. Unexpected demand increases or decreases can throw off the entire production schedule.

Secondly, JIT involves smaller batches and more frequent deliveries, so there is a greater likelihood of disruptions in the supply chain. This could lead to production delays and, ultimately, lost revenue.

Finally, JIT manufacturing can be expensive, as it requires significant investment in inventory management and other operational processes.

3. Who invented just-in-time manufacturing?

Toyota invented just-in-time manufacturing in the 1950s. The company developed the system to improve its efficiency and competitiveness. It is now a technique used worldwide to ensure that businesses take to heart the importance of time and take a critical look at other efficiencies that they can introduce in the business that they are in.

4. What benefits do manufacturers draw from just-in-time delivery?

Just-in-time delivery offers many benefits for manufacturers. Perhaps the most obvious benefit is that it can help to reduce inventory costs. In addition, just-in-time delivery can help to improve production efficiency. Finally, just-in-time delivery can also promote better relationships with suppliers.

Customer Reviews

Customer Reviews