The better you care for your assets, physically or otherwise, the longer they stay in service. That’s easy enough, right? According to Forbes, unplanned downtime due to poor maintenance costs industrial manufacturers $50 billion dollar a year (and this is just a ballpark figure). Focusing on asset maintenance is key to slowing down, if not stopping, this financial leak.

Conducting maintenance is labor-intensive and time-consuming. You need to track what maintenance work has been completed and what is pending. This is difficult even if you work in a small factory as there’s a lot of equipment to go over. Enter, SlideTeam.

We present the Top 10 Maintenance Report Templates to help you stay on top of equipment maintenance, present maintenance reports to relevant personnel, and reduce losses due to downtime. Let’s tour these Slide Decks and see which one best fits your needs.

Template 1: Maintenance Report Time Spend Task Performed Organization Planned

This PPT Deck will act as your man FRIDAY when it comes to maintenance reports. Each slide is a unique form to address equipment maintenance procedures with checklists and tables to record your work. It includes computer system details, key tasks, services done, key areas of in-house maintenance, and more. Download this template now to ensure holistic equipment care.

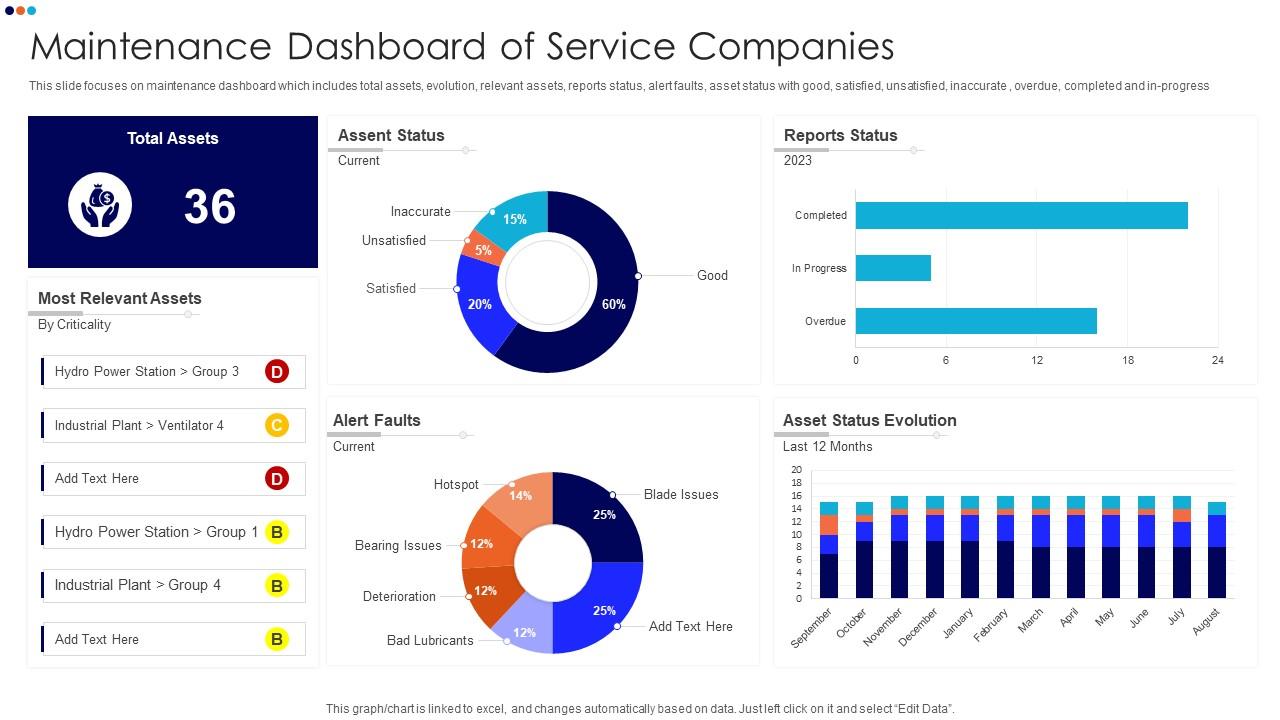

Template 2: Maintenance Dashboard Snapshot Of Service Companies

This PPT Slide is an excellent tool for recording and presenting maintenance services. It shows the total asset, asset status, alert faults, report status, and more. Download this template from the link below to paint the big picture of your maintenance work.

Template 3: Maintenance Dashboard For Monitoring And Reporting Operations

Deliver a neat maintenance report with this dashboard PPT Theme. Use tables and visuals to present information such as maintenance order status, current status, advance warnings, a summary of work, and more. Download this template right away to monitor and report how well your assets are operating, if intervention is needed, and when.

Template 4: Preventive Maintenance Report With Total Cost

Preventive maintenance saves you a significant portion of your revenue at a comparatively negligible cost. You can keep track of this cost and present it to relevant stakeholders using this PPT Slide. Present details on finished and unfinished work, time spent on maintenance, costs in labor and parts, etc. Download this template now.

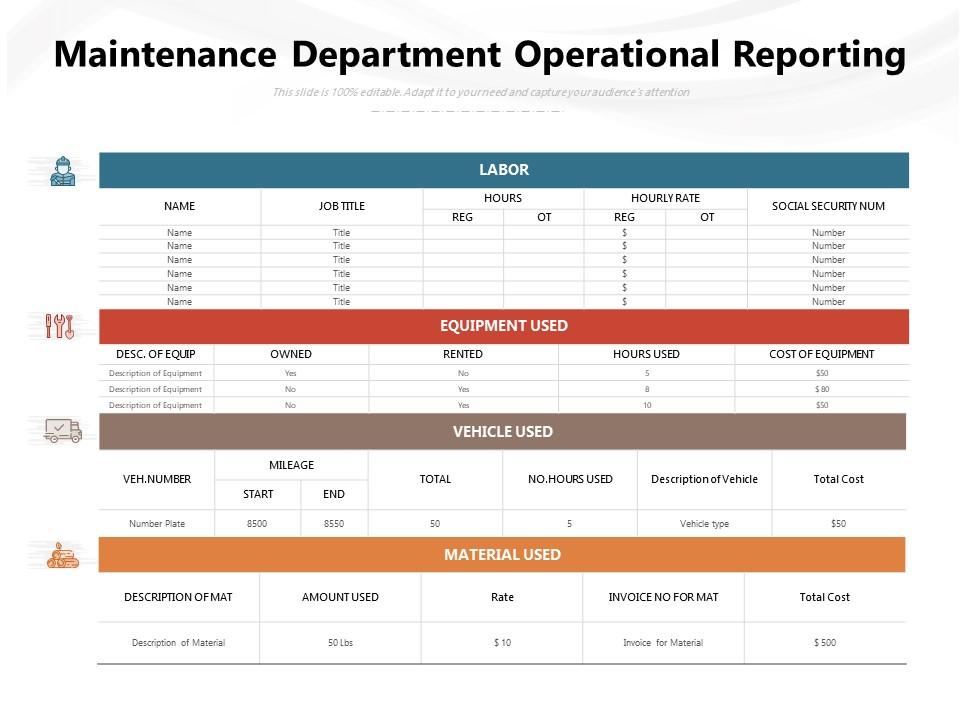

Template 5: Maintenance Department Operational Reporting

This PPT Slide has been designed to track the maintenance department’s work. Use it to record and report key performance indicators (KPIs) such as the use of labor, equipment, vehicle, and material. The hours worked by the employees, equipment rented or owned, vehicles used, material bought, etc., can all be noted using this presentation. Use this to showcase how skilled you are in sensing and designing the maintenance needs of any business. Download it here.

Template 6: Equipment Maintenance Report With Key Tasks

Download this single PPT slide to design and present a report for your equipment maintenance tasks. With the date, equipment name, and manufacturer’s name added, note down the task description, the employee’s name, and the validation date before the machine is put back into service. Stakeholders are bound to be impressed by such due diligence. Get this template right below.

Template 7: Maintenance Review Frequency Equipment PowerPoint Presentation

A rule of thumb for any work is that it should NOT take you longer to plan than to do. Plan out your maintenance work with this PPT Theme. Note down the date, equipment, parts needed, engineer name, frequency of maintenance, etc, in this tabular layout. Download this presentation template now.

Template 8: Maintenance Review Service PPT Presentation

This is a template similar to number 7 above with a color scheme in the blue spectrum. Add your maintenance review details like the date, frequency, parts needed, status, and more in an eye-soothing tabular PPT Slide. Download this template right away!

Template 9: Determine Mobile Device Maintenance Checklist Management And Monitoring

This PPT Slide is a simple tabular presentation that will make your work a breeze. Separate your work into frequency columns of daily, weekly, monthly, and quarterly, with tasks placed in rows such as backup maintenance, virus scanning, security patches, etc. Download this template now to have a handy checklist by your side!

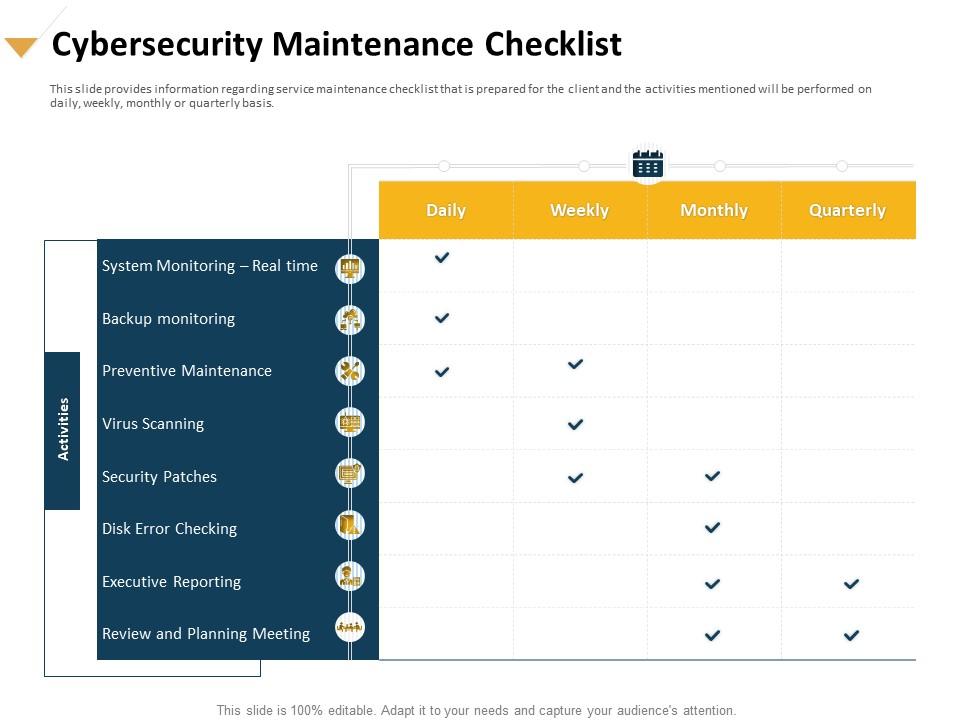

Template 10: Cybersecurity Maintenance Checklist Preventive Maintenance PPT

With a manufacturing-heavy template list, we wanted to end with a maintenance checklist for cybersecurity assets. Similar to the checklist in Template 9, the list is tabular with maintenance frequency in columns and the tasks in rows such as disk error checking, virus scanning, security patching, etc. Download this template to ensure your software can run as long as the hardware!

Regular Check-ups are Important

A thought-out maintenance schedule for your equipment will do wonders for your company’s financial goals. Unexpected breakdowns and downtime have cost industries billions upon billions in repairs and new equipment. This doesn’t have to be the case. Use our content-ready and 100% customizable Maintenance Report Templates to boost your equipment’s productivity.

PS It is not just big machines that need maintenance, it is also miniature devices like simple light bulbs that need care. Check out our facilities maintenance blog here, (with templates included) to round out your asset management plans.

FAQs on Maintenance Reports

How do I write a monthly maintenance report?

To write a monthly maintenance report, follow these steps:

- Identify the purpose and audience of the report. This will help you determine the level of detail and the type of information to be included.

- Gather data and information on maintenance activities that were performed during the month. This may include information about equipment repair, preventative maintenance tasks, and any issues or problems that were identified and addressed.

- Organize the information into an easy-to-read format. Use headings and subheadings to break up the report and make it easy to skim through.

- Include a summary of the key takeaways from the report. This should include an overview of the maintenance activities performed, any issues identified and addressed, and any recommendations.

- Review and edit the report for accuracy and completeness. Make sure that all information is accurate and up-to-date.

- Distribute the report to the appropriate stakeholders. This may include management, maintenance staff, and other departments that maintenance activities affect.

- Follow up on any recommendations or action items. This will help ensure that maintenance activities are effective and issues are addressed in a timely manner.

What are the 3 types of maintenance?

There are three main types of maintenance: preventive maintenance, predictive maintenance, and corrective maintenance.

- Preventive maintenance: This type of maintenance is scheduled in advance and is designed to prevent equipment failure and prolong its lifespan. Preventive maintenance tasks include regular inspections, cleaning, and replacement of worn parts.

- Predictive maintenance: This type of maintenance uses data and analytics to predict when equipment will fail. This allows maintenance teams to schedule repairs and replacements before a failure occurs. Predictive maintenance techniques include vibration analysis, thermal imaging, and oil analysis.

- Corrective maintenance: This type of maintenance is performed in response to equipment failure or malfunction. Corrective maintenance tasks include repairs, replacements, and troubleshooting to restore equipment to its normal operating condition. It is the costliest, by far.

What is SOP for maintenance?

A Standard Operating Procedure (SOP) for maintenance is a document that outlines procedures and processes that should be followed for the maintenance of equipment, facilities, and infrastructure. It is a set of instructions used to ensure consistent and efficient maintenance practices.

An SOP for maintenance includes the following information:

- Objectives: The purpose of the SOP and the goals it aims to achieve.

- Scope: The equipment, facilities, and infrastructure that the SOP covers.

- Responsibilities: The roles and responsibilities of the personnel involved in the maintenance process.

- Procedures: A step-by-step guide on performing maintenance tasks, including safety precautions and the use of any specialized tools or equipment.

- Checklists: A list of items that need to be checked or inspected during the maintenance process.

- Forms: Any forms that need to be filled out or signed during the maintenance process.

- References: Any additional documents or resources

- Review and approval: The process for reviewing, approving, and updating the SOP.

What are the 5 basic maintenance skills?

The five basic maintenance skills that are essential for any maintenance worker include:

- Technical skills: A good understanding of the equipment and systems being maintained, including how they work, how to troubleshoot problems, and how to repair or replace parts.

- Mechanical skills: The ability to use hand and power tools. The practice of basic mechanical skills such as welding, soldering, and fabrication.

- Electrical skills: Knowledge of electrical systems, including wiring, circuits, and electrical safety.

- Problem-solving skills: The ability to identify and diagnose problems and to develop and implement solutions.

- Communication skills: The ability to communicate effectively with other members of the maintenance team, as well as with other departments and stakeholders.

Customer Reviews

Customer Reviews

![Top 10 PPT Templates to Fulfill Your Trade Marketing Goals [Free PDF Attached]](https://www.slideteam.net/wp/wp-content/uploads/2022/03/Top-10-Trade-Marketing-Templates_1-1013x441.png)