“What went wrong and why?” These are the words that everyone in manufacturing dreads to hear or say. It would be so much better if the errors had been filtered out before it went to the execution phase.

Is there a mechanism to do this? Yes, there is and it is called Failure Mode and Effects Analysis (FEMA). The purpose of this tool is to identify potential problems, or "failure modes," and to assess potential effects of those failures. The goal is to then take steps to eliminate or reduce the chances of occurrence of these failure mode. It is typically used during the design phase of a project, but can also be applied to existing products and systems.

FMEA can be used for any type of system, product, or process. It is used in manufacturing and engineering, but can be applied to any type of system. It is a systematic, proactive method for evaluating a process or product to identify where and how it might fail. It also assess the relative impact of kinds of failure, to zero-in on areas that need improvement.

The Best FMEA Templates to Get Ahead of Failure

What does the implementation of FMEA look like? How does one conduct it? How long does it take? All these and more questions will be on the minds of your teammates as this philosophy is introduced to them. To get them up to speed and implement FMEA quickly without failure, we have curated 10 PowerPoint templates to help you out.

There is also a helpful FAQ section at the end of the blog to clarify any doubts the audience may have. Let’s get started.

Template 1: Failure Mode and Effects Analysis (FMEA)

This PPT Deck is perfect for corporates, specifically production companies, that want to identify potential risks. The set covers the details related to sections such as FMEA process overview, team structure and responsibilities, possible effects and cause of the failure, etc. Download it now.

Template 2: FMEA to Identify Potential Failure Modes

This PowerPoint bundle covers all aspects of the process, from process overview and team structure to risk assessment and action steps. Plus, the RPN calculations are second to none. If you’re looking for a thorough, informative, and persuasive presentation on FMEA, your search ends here. Get it now.

Template 3: FMEA Method For Evaluating a Process

This PPT set covers all the critical aspects of the process, from process analysis and fundamental failure modes to potential effects of failure mode and FMEA scoring. The presentation is full of critical information and analysis, presented in an easy-to-understand manner. Download it now.

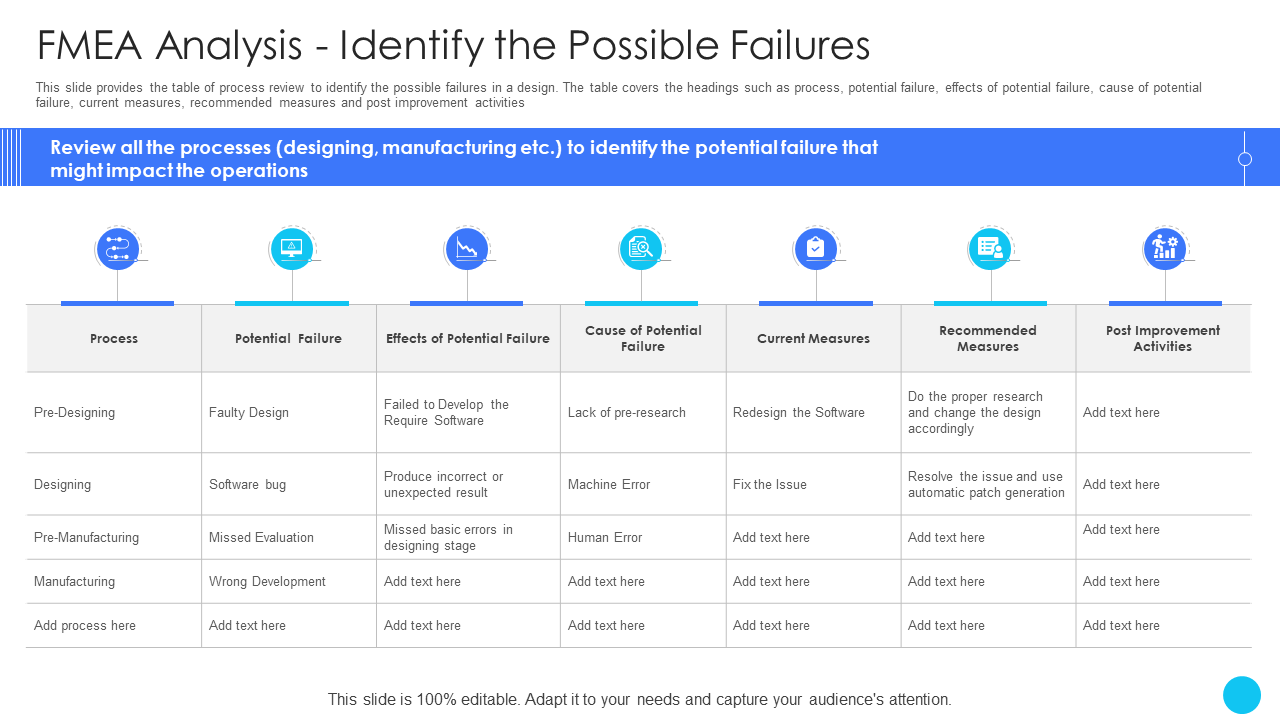

Template 4: FMEA - Identify the Possible Failures Challenges and Opportunities

This PPT Layout covers key areas such as process, potential failure, effects of potential failure, cause of potential failure, current measures, recommended measures, and activities to improve the impact or implementation of FMEA. You may use this slide to improve your product design and avoid costly mistakes. Get it now.

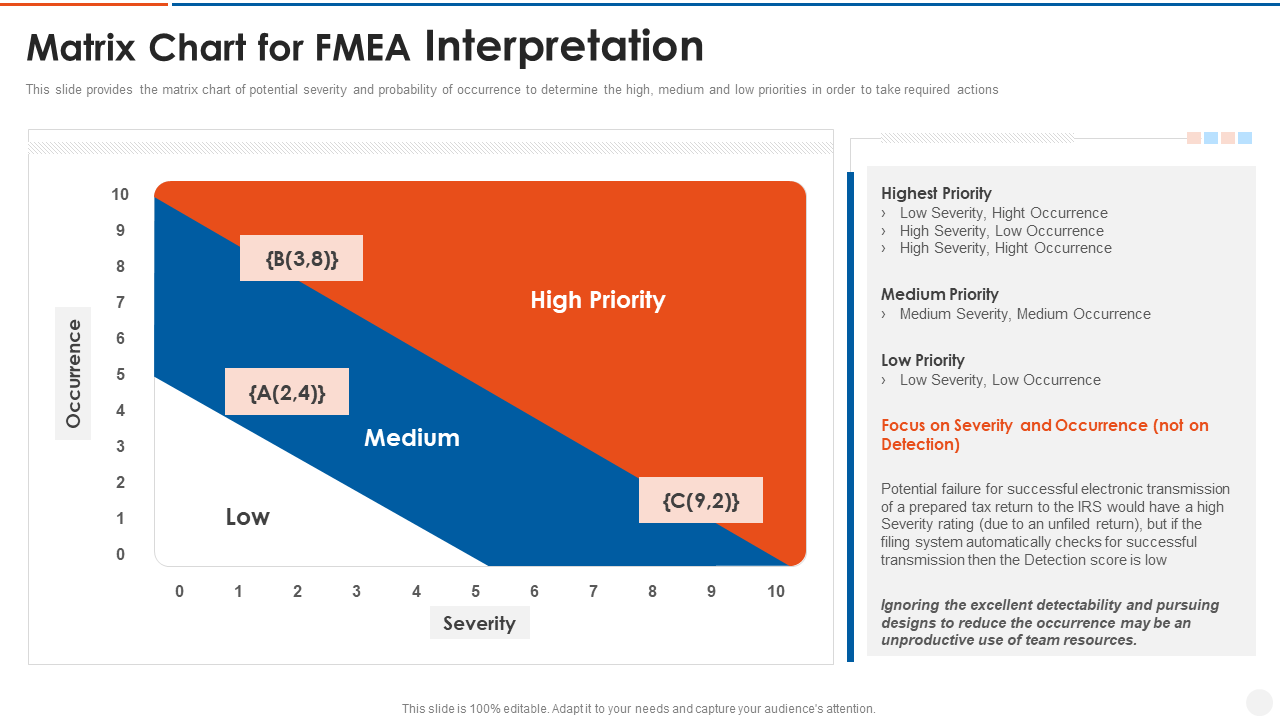

Template 5: FMEA Matrix Chart for Interpretation

The matrix chart PPT theme lists potential severity and probability of occurrence, so you can quickly identify which areas are high priority, medium priority, and low priority. This is valuable information when making decisions about next steps and corrective actions. Download it from the link given below.

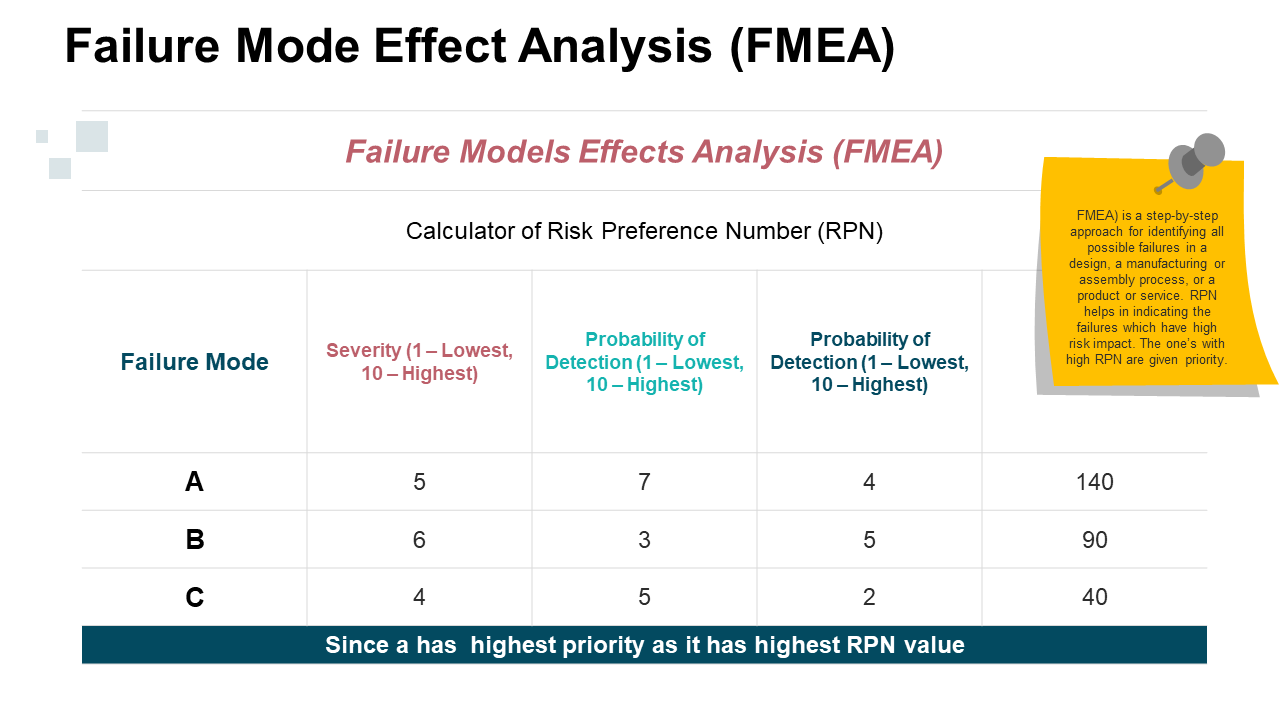

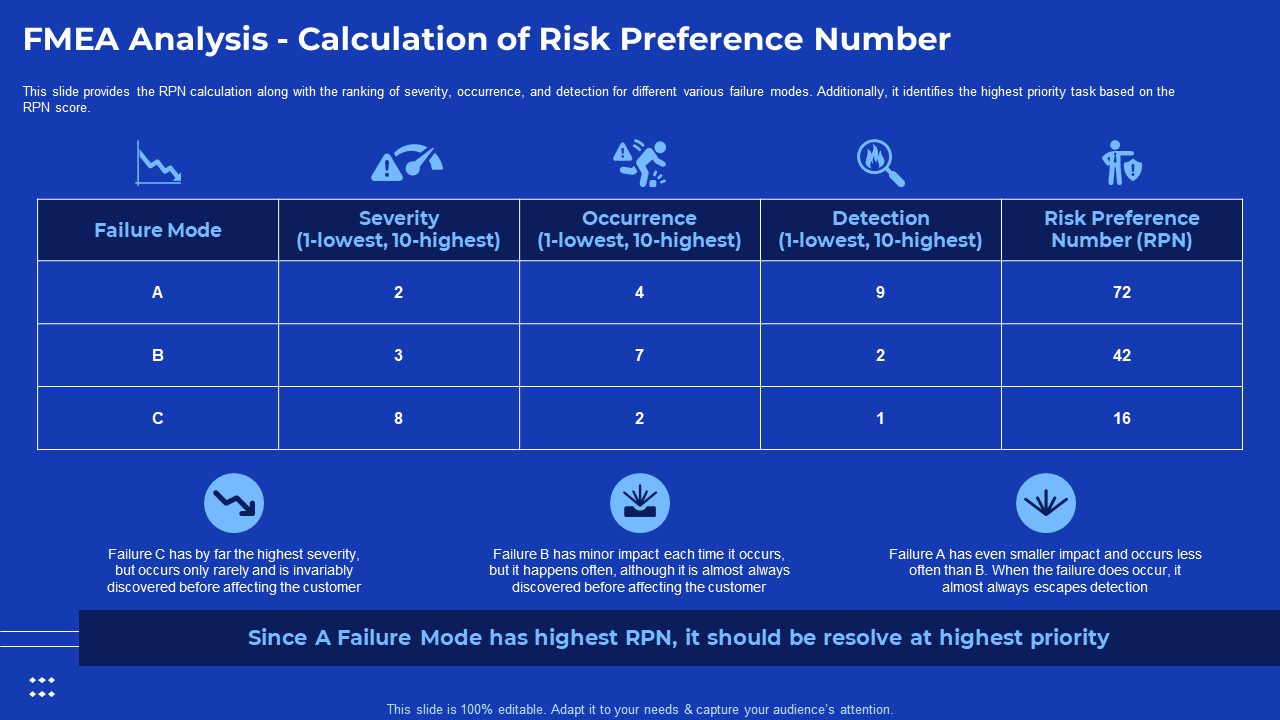

Template 6: FMEA RPN PPT

Use this PowerPoint Slide to calculate the severity of several failure modes through the Risk Preference Number (RPN). The resultant data will help you choose the preferred method of execution for the process. Make this a part of your business execution strategy now.

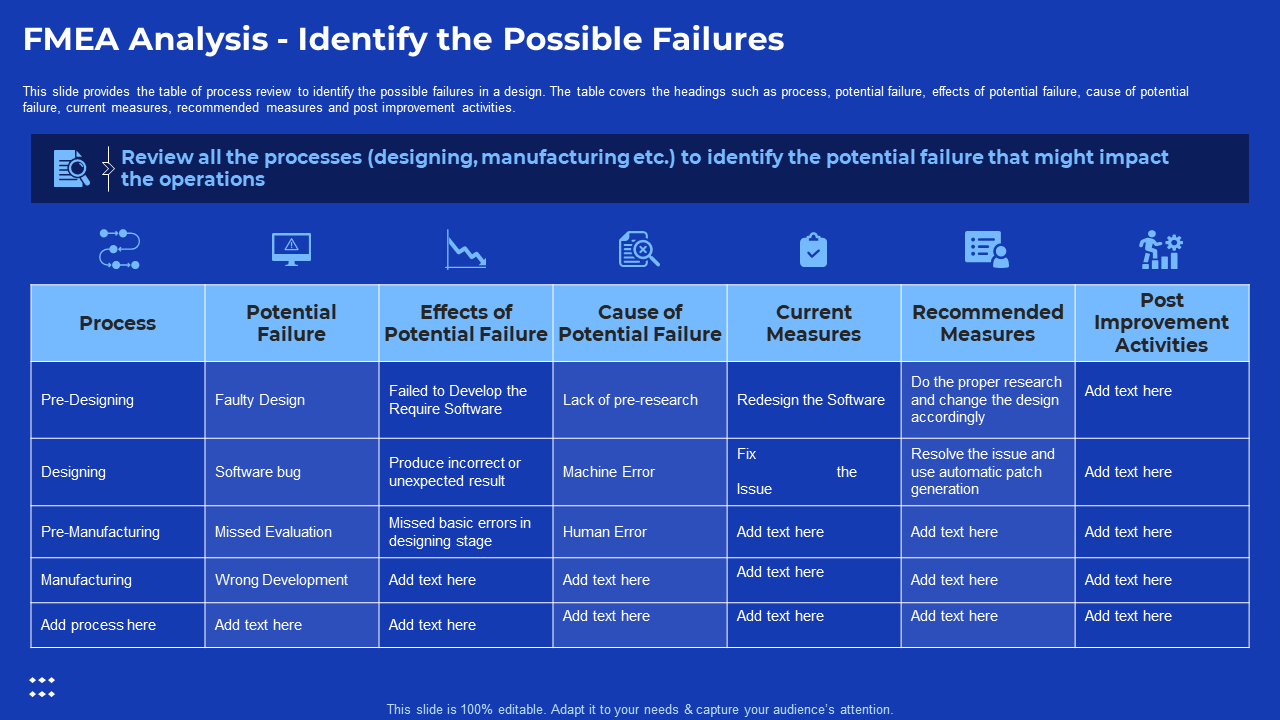

Template 7: FMEA - Identify Process Improvement in Banking Sector

This PPT Preset helps identify potential failure points and provides recommendations for improving the design. It provides a table of potential failure points for the banking sector. The table covers headings such as process, potential failure, effects of potential failure, cause of potential failure, etc. Download it now.

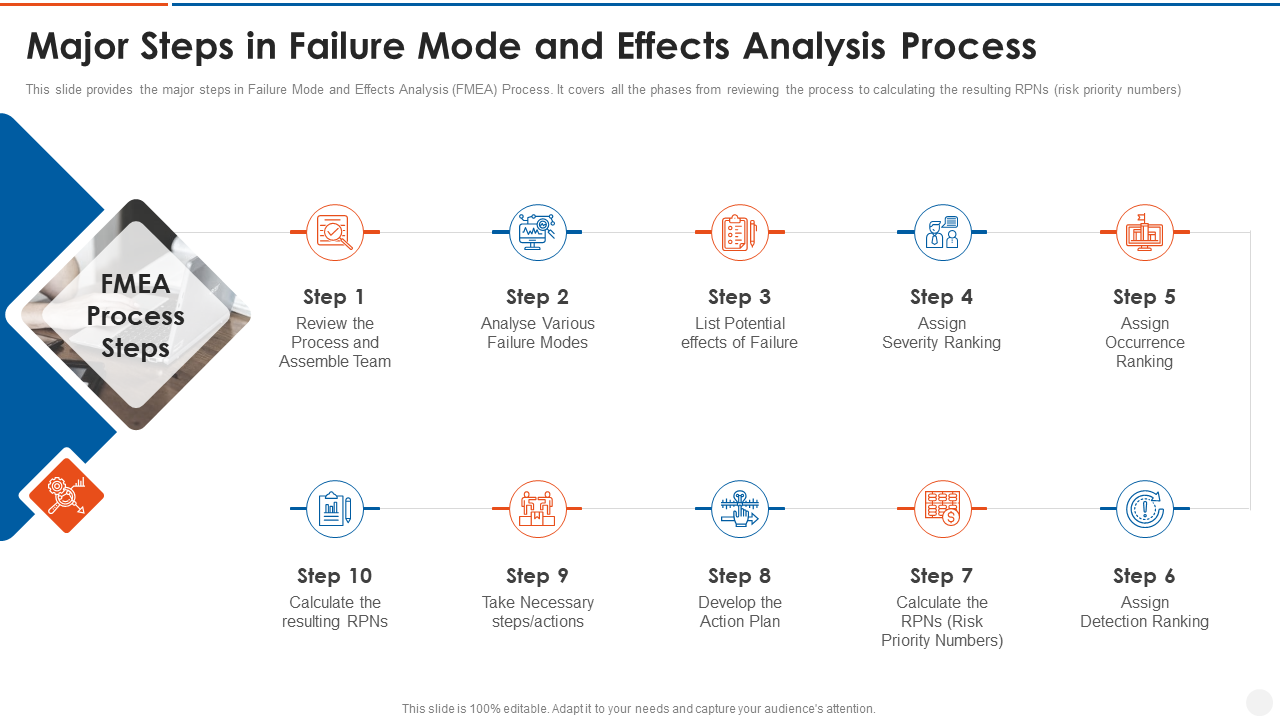

Template 8: Major Steps in FMEA Process

Covering all the key phases of the process, from reviewing the process to calculating risk priority numbers, this PowerPoint Deck is essential reading for anyone wanting to master FMEA. Why wait? Get ahead of the competition and learn everything there is to know about this important analytical tool today!

Template 9: FMEA Calculation Process Improvement in Banking Sector

Every process in the banking sector can have different failure modes. To ensure that a process is functioning well, FMEA analysis is essential. This particular slide provides the RPN calculation along with the ranking of severity, occurrence, and detection for kinds of failure modes. Download it now.

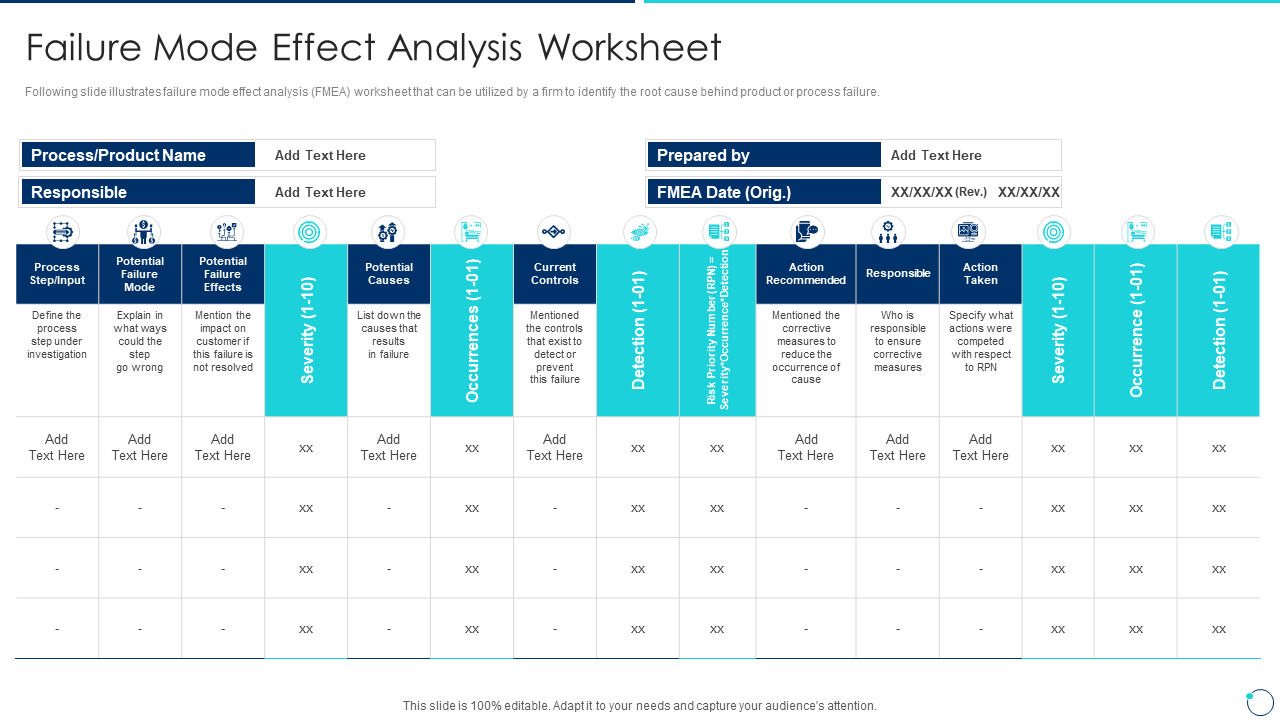

Template 10: FMEA Worksheet Collection Of Quality Control

With its easy-to-use format, the FMEA Worksheet Collection makes it simple to identify potential failure modes and effects during the design and development phases of product creation. With the detection of problems early on in your process, you can save time and money in the long run. Download it now.

The Final Word

FMEA is a powerful tool that can be used to improve the quality of products and processes. It needs to be in your organization.

Download our FMEA templates now to ensure quality control!

FAQs on FMEA

Is FMEA a Six Sigma tool?

Yes, FMEA is definitely a Six Sigma tool. In fact, it's one of the most commonly used tools in Six Sigma (this itself means defects are to be kept at less than 3.4 per million iterations of the process or event).

FMEA is particularly important in Six Sigma because one of the main goals of Six Sigma is to reduce process variability. By identifying potential failure points and then taking steps to address them, organizations can significantly reduce process variability and improve overall quality.

What are the steps to FMEA Analysis?

The first step in conducting an FMEA is to identify the potential failure modes for a process or product. A failure mode is defined as a way in which a process or product can fail to meet its intended purpose.

Once the potential failure modes have been identified, the next step is to assess the potential effects of each failure mode. The impact of a failure mode is typically classified as either major, minor, or no impact.

After the potential failure modes and their effects have been identified, the next step is to identify the causes of each failure mode. The causes of failure can be classified as either internal or external.

Internal causes are typically things that are within the control of the organization, such as design flaws, process deficiencies, or material defects. External causes are typically outside the organization’s control, such as environmental factors or customer demands. Once this is done, we come to the corrective actions that need to be taken. There are designed to eliminate or reduce the chances of a failure mode occurring.

After the corrective actions have been identified, the final step is to implement the corrective actions and to monitor the process or product to ensure that the corrective actions are effective.

When conducting an FMEA, it is important to use a systematic and logical approach. The steps outlined above are a general guide that can be followed when conducting an FMEA.

What are the types of FMEA?

There are two main types of FMEA: Design FMEA and Process FMEA. Design FMEA is used to identify potential problems with a new product or system before it is manufactured or used. Process FMEA is used to identify potential problems with an existing manufacturing or assembly process

Download the free FMEA Templates PDF.

Customer Reviews

Customer Reviews

![Top 10 ESG Framework Templates to Build an Eco-friendly Enterprise [Free PDF Attached]](https://www.slideteam.net/wp/wp-content/uploads/2022/02/Top-10-ESG-Framework-Templates_1-1013x441.png)